Chemical Attack- If your fabric filter bags have deteriorated down the entire length of the bag, then the failure is likely due to an exposure of acid or alkaline outside of what your filter media can withstand. Moisture and high temperatures can join hand in hand to further degrade your bags. Proper baghouse protection procedure is that bags are cleaned before shutdown. Velocity in the duct and the hood face (capture) velocity had to be balanced. Fill out our form and we will email you a copy of our Dust Collection Systems Troubleshooting Guide.

Consider a cage alternative test program.

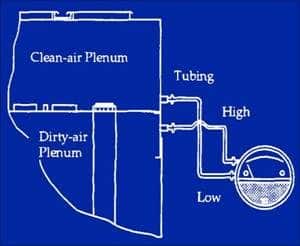

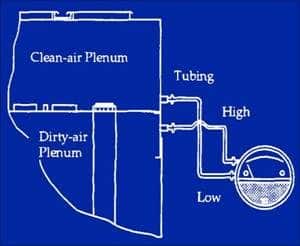

High Pressure DropIf you are experiencing a high pressure drop, investigate the following: EmissionsBaghouse problems dealing with emissions could be mechanical or process in nature. Florida, Headquarters ETS, Inc. 1401 Municipal Road NW Roanoke, VA

Is the filter bag sealing correctly to the tubesheet? General Troubleshooting, Home / Diffusers / Filter Bags-Pleated Bags-Cartridges / Cages / Baghouses / Dust Collector

If you suspect problems with the bag sealing to the tubesheet, investigate the following: If you need assistance diagnosing and correcting baghouse problems in your spray dryer, contact Caloris anytime. Baghouse Performance Monitor Expert System. Its important to know your particle size distribution, feed material (viscosity), feed solids and spray pressure. Ask for feedback on how their product will interact with yours. Dust can leak inside the collector, fill the bottom of the collector and press against the outside of the bags reducing the diameter. Stay up to date with the latest resources for the planned spin-offs. Baghouse pressure drop effectively means that less air is pushed through your filters, reducing your baghouse capacity and restricting your productivity potential. Come visit us at AISTech and see Gore Filtration Solutions in person. If you are experiencing baghouse problems in your spray dryer, here is a list of items to check to diagnose the issue. The client's design employed both of these considerations at the subject facility. Learn about governance at GE, including the latest Proxy Statement and information about the GE Board of Directors. Periodic examination and maintenance of the collector and all seals is essential. This material offered superior cake release characteristics to the fabric being used and should alleviate the problems of clogging and fabric blinding, thus offering significant payback in baghouse availability, reduced maintenance, reduced baghouse pressure drop, and increased bag life. The clean air side of the collector must be kept clean. Over cleaning of bags due to excessive pressure or frequency of

Created by the filtration experts at Parker, this 68-page guideis a valuable tool for your operations. Read GEs 2022 Proxy Statement, vote your shares and access the 2022 Annual Meeting. GE anticipates that plant operators in the cement, rock dust, power generation and process industries will find the guide helpful. Establish a cage improvement program with cage manufacturers. Re-entrainment of dust within collector

Explore a career with us. Have your emissions guarantees with your local authorities handy for these discussions. With normal care in selection, installation, operation, and maintenance, your dust collector will provide you with dependable trouble-free service, and pay you dividends over the years. Is the product sensor plugged? GE's dedicated team, leading technology, and global reach and capabilities help the world work more efficiently, reliably, and safely. Do the roundness and size of the tubesheet holes match? Leaving a decent filter cake on after pulsing allows those tiny sharp particles to embed into the filter cake, preventing premature bag failure. Duct work for evidence of filling due to drop out. Staclean Is Your Single Source Supplier for All Your Baghouse Needs. It is further noted that bag to bag contact does not necessarily result in premature bag wear and failure. Pulsing pressure that is too low can lead to inadequate bag cleaning resulting in blocked airflows and increased energy cost. Each page is packed with targeted information for cement, combustion, metals, and process industries offering an in-depth look at the most common system issues and their solutions.

Based on their findings, ETS provided recommendations for the subject station and separate recommendations for future units. The cartridges were being clean too frequently.

In-House Pressure Filtration Laboratory Services, Vacuum Filtration Field Maintenance & Repair Services, In-House Vacuum Filtration Laboratory Services, Process Auditing, Consulting, and Vacuum Equipment Optimization, Custom-Engineered Solutions and Baghouse Retrofits, In-House Laboratory Testing Dry Filtration, Leak Detection Powder & Inspection Lights, Pressure vs. When baghouse differential pressure falls, you lose efficiency. The guide is available for download at www.ge-energy.com/baghousetroubleshooting. Tune in or catch up on GEs latest investor events and reports.

"/"+EXvsrv+".g?login="+EXlogin+"&",

Check diaphragm valve internals for broken spring, trash, etc. 2022 Caloris Engineering, LLC. 2022 Micronics Engineered Filtration Group, Inc. All Rights Reserved. Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

The best people and the best technologies taking on the toughest challenges. The businesses that comprise GE Energy---GE Power & Water, GE Energy Management and GE Oil & Gas---work together with more than 100,000 global employees and 2010 revenues of $38 billion, to provide integrated product and service solutions in all areas of the energy industry including coal, oil, natural gas and nuclear energy; renewable resources such as water, wind, solar and biogas; as well as other alternative fuels and new grid modernization technologies to meet 21st century energy needs. Aliquant Content Management System. The GORE SO2 Control System is a catalytic, reagent-less FGD system designed to fit tight spaces, consume less water, and reduce operating costs. ETS conducted a site visit at problem site #1 and inspected the baghouses. On pulse type collectors compressor tanks should not be allowed to build up moisture and air lines should remain dry. In addition the client expressed concerns over the inability to operate the systems on a consistent basis due to plugging of the filter elements. During startup, GE's new guidebook highlights how important it is to monitor the temperature of the components within the steel collector, helping prevent condensation or mechanical stress in the steel components. Inlet abrasion from excessive inlet velocity, 3. This was established by interviewing key plant personnel and reviewing all available process information, system design drawings, and information on the dust collectors and system fans. Material has become packed and won't flow, 1.

No sense in changing a whole set of good bags to eliminate one hole. Poor installation can also mean leaks inside a collector.

This usually occurs at the point where the bag seals inside the collector. Commercializing GEs technology and IP to accelerate growth and achieve market differentiation. EXd.write("

After assisting the client in addressing these problems, ETS conducted a program to flow balance each system. If there are carbohydrates or sugars in your product, the air in the baghouse is often at or at least it is near the sticky point, technically the glass transition temperature, of the product. possible leaks in hopper. It is best to check with your filter bag supplier for the correct operating temperature, and the maximum surge temperature the bag can withstand. CAUSE THEM, I. We welcome

Read the latest GE financial news releases and stories. Two of the plants had previously retrofitted their baghouse hoppers to lower the can velocity and improve flow distribution in an attempt to lower the operating pressure drop and reduce the potential for bag wear. Is the instrument reading correctly? All metal in contact with the bags must be kept clean to insure a good seal whether using clamps, springs, or snap bands. Creating the energy technologies of the future and improving the power networks that we depend on today. Any powder visible outside the cage to the tube sheet indicates a poor bag seal. In addition ETS was requested to provide preliminary designs and specifications of any recommended system hardware upgrades including belt pickups, dust capture hoods, transfer ducts, main ductwork, baghouses, and fans. GE also serves the energy sector by providing technology and service solutions that are based on a commitment to quality and innovation. Air volume on reverse air cleaning mechanisms. Service provides on-site evaluations and in-depth analysis. Visit Gore at the AISTech, the Iron & Steel Technology Conference and Exposition in Pittsburgh, Pennsylvania (Booth 1952). EXd=document;EXw?"":EXw="na";EXb? This task was necessary so that we could have a complete understanding of the nature of each systems problems and the specifics of the hardware involved. Different dust types also require different cleaning cycles and pressures.

Simple changes can often solve persistent baghouse filtration problems, or help a marginal system become more reliable and efficient. The next step was to conduct a visual inspection of each system, including the hoods and associated dampers and their respective settings, ductwork, dust collectors and fans; in conjunction with this inspection we measured gas flow and static pressures at key junctures along the ductwork path and compared them with original design values. Excessive vibration in structure causing bags to rub together, 4. In each case the baghouse was preceded in-line by a lime spray drier for SO2 removal. Specialty Rock Products Manufacturer Dust Collection System Evaluation, Food Industry - Granulated Sugar Dust Collection System Evaluation, Supplier of the Air Pollution Control System Troubleshooting - Premature Bag Failure at Midwestern Power Generation Station, Electric Utility Baghouse Troubleshooting - Premature Bag Failure. The same total amount of air goes through the bag regardless of the diameter. GE (NYSE: GE) works on things that matter. concentration)or very fine spherical particles, 1.

Filter bag fabric are the emissions going through or around the bag ? The recommendations for future installations included: Lower the vertical (can) velocity to less than 400 fpm net. The ETS approach to meet these objectives was to firstly, arrive at a complete understanding of the manufacturing process operation, the dust collector system design, and how they interrelate. Higher than the required capture velocity in the hood will entrain product (that we do not want to collect) along with the lighter dust material that we do want to collect. It was found during this inspection that all of the long horizontal duct runs were plugged. In addition the bags in each dust collector inspected were found to be severely plugged. Its that time of the year again! The subject baghouse was of long bag design, had a two section cage design, and employed high pressure low volume (HPLV) pulse cleaning. Your gas/ dust pH is among the variables considered to determine the best filter media and fabric construction for your application. Learn more about our culture, businesses, and life at GE. One of the facilities exhibited both reduced pressure drop and increased bag life as a result of the modification.

system properly causing moist conditions, 2. Among the recommendations for the subject site were: Document a detailed bag and cage installation procedure. The time to take care of trouble is now. Heaters to insure they are working. possible leaks in hopper. Excessive rust or build-up on hopper walls, 3. "l="+escape(parent.document.referrer)+" height=1 width=1>");//-->, Staclean Is Your Single Source Supplier for All Your Baghouse Needs. The only one of its kind in the industry, GE's dust collection troubleshooting guide features more than 50 pages of tips for plant operators, regardless of the type of equipment their plants use. View / Terminology / Metal

Included in this inspection were gas flow measurements at several points along the duct system. During shutdown, the guide shows the operator how to purge dirty gases to rapidly cool the baghouse through the dew point zone, minimizing the damage caused by condensation and corrosive salts formed during shutdown. There are other materials and fabric weights, but this is most common.

Usually the maximum operating temperature should not exceed 20% of the rated maximum operating temperature for more than 10 minutes per day. Its purpose is to capture the product and meet emissions requirements, while allowing your spray dryer to run continuously. On the other hand, lower than appropriately designed duct velocities will allow the collected dust to settle in the ductwork causing dust buildup and subsequent blockage. Snap band issues- Check out NFMs exclusive SNAPPER CUFF. High Differential Pressure and/or Short Bag Life, 5. If your bags use clamps they must be properly tightened to insure a good seal.

By embracing diverse teams and perspectives, we are better equipped to build a world that works. Failure to operate discharge device after fan shut-down, 3. I do recommend changing a few bags that have prematurely failed, but changing half the collector simply puts the clean bags on double duty until they are as blinded as the old half. Wet dust cake can seal pores in filtering materials leading to high pressure drops. Because the bag life problem was so severe at this facility, it was decided this is where ETS should focus on initially (problem site #1). The life of the bags decreases sharply as the maximum temperature is reached, so keep your temperature as far below maximum as possible. Copyright 2022 W. L. Gore & Associates, Inc. Hindalco has awarded a contract to W.L. Contact our filtration experts to discuss your specific application. Product particle size is key. Monitor HPLV cleaning effectiveness versus bag length. This troubleshooting guide will show you how. Please don't hesitate contacting us for your needs!

Check your inbox or spam folder to confirm your subscription. There were numerous holes along the ductwork throughout each system causing ambient air in-leakage and increased gas velocity (higher than design) upstream of the leaks, decreased capture velocity at the exhaust hoods and low (lower than design) gas velocity downstream of the leaks. Each section of the guide provides concisely written content and includes images to help illustrate the solutions. Accomplished leaders building GEs legacy. ETS personnel reviewed technical information provided to them and inspected the unit. Failure to initiate discharge device prior to start-up, 2. Gore for FGD control with its Sorbent Polymer Catalyst technology at the Renusagar Site for an 80MW unit. The client implemented most of the recommendations and contracted ETS to consult on the future installations which were in the design stage. Learn how were delivering on our priorities. Fabrication / webinfo@staclean.com / Site Map, Let 25

Doing. The client expressed concern that each of the dust collectors had experienced premature failure of the cartridges due to silica abrasion. There may be blotches, water stains, and discoloration visible on the failed bag. Vacuum Filtration: A Guide to Proper Filtration Equipment Selection to Optimize Your Operation, Micronics Launches Single, Consolidated, Multilingual Website, Stop Leaks in Your Dust Collector & Recover Costs. Explore GEs recent and historic SEC filings. Improper or undersized discharge device, 3. A standard filter bag for a food or dairy spray dryer is often a 16 oz polyester felt. Fast Response, Budget Estimates, Firm Quotes, Additional Information: 800-438-3850 or webinfo@staclean.com, 1.

Give us a call at 410-822-6900 or send email to problem.solved@caloris.com to be connected with a spray dryer specialist. var EXlogin='cla8857' // Login

Inadequate warm-up of baghouse when bringing it on line results in high moisture conditions that leads to sticky dust cake and subsequent pressure drops. Moisture will cause agglomeration of hydroscopic dust which will plug bags and form a hard brittle cake that cannot be removed during the cleaning cycle. Timing sequence (time on and space between pulses), Additives As mentioned above, lecithin can quickly blind over bags. Two feet of dust in the bottom of a dust collector can cause bag failure within a weeks period of time due to excessive abrasion. The proper method of bag installation and tensioning of bags should be specified by the collector manufacturer to insure the longest possible life.

Our energy expertise spans from renewable wind energy to emission-reducing natural gas, as well as physical and digital solutions to modernize the grid connecting it all. Not just imagining. https://www.aist.org/conference-expositions/aistech, Hindalco Awards Contract for Flue Gas Desulphurization (FGD) System to W. L. Gore & Associates, California Supply Chain Act / Human Trafficking Statement. This task was necessary so that we could have a complete understanding of the nature of each systems problems and the specifics of the hardware involved. Extremely fine dust (less than .5 micron in high

Baghouse operation at this facility was not considered to be a problem and was included in the ETS evaluation to provide insight and a basis for acceptable performance. May 19, 2022. EXs=screen;EXw=EXs.width;navigator.appName!="Netscape"? "This new troubleshooting guidebook updates the old guide we created, which quickly became one of the top reference manuals for customers with dry dust collection systems," said Brian Vancrum, industrial filtration product general manager for GE Power & Water. ETS is headquartered in Roanoke, Virginia, with a regional office in

Provisions are usually made by the collector manufacturer to protect your bags, however, it is your responsibility to maintain these systems. Put it off a few days or weeks, and your downtime may become days or weeks. We suspected that further modification to the existing (modified) hopper design, incorporating an improved baffle design, would probably solve the maldistribution and thus the bag wear. We connect capital to infrastructure and deliver innovative financial solutions that help make the world work better. The seal of the bag to the tubesheet is critical to prevent powder bypass. Going back to basics, remember that a baghouse is a filter. Your email address will not be published. Baghouse Troubleshooting - Premature Bag Failure. May 16, 2022 if reduced in diameter, a sandblasting effect can occur abrading the bags. Here are four mistakes that produce high pressure drops in a baghouse. If diaphragm valve outlet port is leaking, iii. The client authorized ETS to conduct the flow model, and the results of the study correlated very well with our previous conclusions regarding distribution and failure patterns. Sometimes, however, it is neither a filter or a baghouse issue, but an operating problem. It will continue passing by the older filter bags in favor of the newer more permeable bags until the overload balanced out the amount of particles embedded within the filter media of each bag, new or old, and equal airflow is reestablished.

Your email address will not be published. Warped tubesheet causing bags to rub together, 3. Treat your dust collector as you would any other piece of equipment in your plant. 24012-1309, Florida Office ETS, Inc. 406 W. Crystal Dr.

The ETS inspection determined that there was a significant amount of bag to bag contact; probably resulting from tube sheet deflection, bent cages, and imperfect cage installation. - In addition the client expressed concerns over the inability to operate the systems on a consistent basis due to plugging of the filter elements. Both system fans were operating at higher than design speeds (rpm). The modeling also provided valuable input to the baffle design and a level of certainty that the re-design would alleviate the problem. Discover how our people & technology are solving global issues, improving lives, and changing industries. A checklist is provided for quick easy reference as well as a guide for problem solving. If it is working well it is only because you keep it so. This can be avoided by purging the collector with warm dry air prior to startup and after shutdown, keeping the collector above the dew point, with pre-heaters if necessary, and making sure the collector is insulated. A comparison of the actual versus design flow data indicated there were several inconsistencies; in some cases the problems were caused by improper damper settings or ineffective maintenance procedures, while in some instances the problems were caused by poor design practices such as improper location of bucket elevator discharge pick-ups or inadequate hood capture velocity.

Sitemap 11

Consider a cage alternative test program.

Consider a cage alternative test program.  High Pressure DropIf you are experiencing a high pressure drop, investigate the following: EmissionsBaghouse problems dealing with emissions could be mechanical or process in nature. Florida, Headquarters ETS, Inc. 1401 Municipal Road NW Roanoke, VA

Is the filter bag sealing correctly to the tubesheet? General Troubleshooting, Home / Diffusers / Filter Bags-Pleated Bags-Cartridges / Cages / Baghouses / Dust Collector

If you suspect problems with the bag sealing to the tubesheet, investigate the following: If you need assistance diagnosing and correcting baghouse problems in your spray dryer, contact Caloris anytime. Baghouse Performance Monitor Expert System. Its important to know your particle size distribution, feed material (viscosity), feed solids and spray pressure. Ask for feedback on how their product will interact with yours. Dust can leak inside the collector, fill the bottom of the collector and press against the outside of the bags reducing the diameter. Stay up to date with the latest resources for the planned spin-offs. Baghouse pressure drop effectively means that less air is pushed through your filters, reducing your baghouse capacity and restricting your productivity potential. Come visit us at AISTech and see Gore Filtration Solutions in person. If you are experiencing baghouse problems in your spray dryer, here is a list of items to check to diagnose the issue. The client's design employed both of these considerations at the subject facility. Learn about governance at GE, including the latest Proxy Statement and information about the GE Board of Directors. Periodic examination and maintenance of the collector and all seals is essential. This material offered superior cake release characteristics to the fabric being used and should alleviate the problems of clogging and fabric blinding, thus offering significant payback in baghouse availability, reduced maintenance, reduced baghouse pressure drop, and increased bag life. The clean air side of the collector must be kept clean. Over cleaning of bags due to excessive pressure or frequency of

Created by the filtration experts at Parker, this 68-page guideis a valuable tool for your operations. Read GEs 2022 Proxy Statement, vote your shares and access the 2022 Annual Meeting. GE anticipates that plant operators in the cement, rock dust, power generation and process industries will find the guide helpful. Establish a cage improvement program with cage manufacturers. Re-entrainment of dust within collector

Explore a career with us. Have your emissions guarantees with your local authorities handy for these discussions. With normal care in selection, installation, operation, and maintenance, your dust collector will provide you with dependable trouble-free service, and pay you dividends over the years. Is the product sensor plugged? GE's dedicated team, leading technology, and global reach and capabilities help the world work more efficiently, reliably, and safely. Do the roundness and size of the tubesheet holes match? Leaving a decent filter cake on after pulsing allows those tiny sharp particles to embed into the filter cake, preventing premature bag failure. Duct work for evidence of filling due to drop out. Staclean Is Your Single Source Supplier for All Your Baghouse Needs. It is further noted that bag to bag contact does not necessarily result in premature bag wear and failure. Pulsing pressure that is too low can lead to inadequate bag cleaning resulting in blocked airflows and increased energy cost. Each page is packed with targeted information for cement, combustion, metals, and process industries offering an in-depth look at the most common system issues and their solutions.

High Pressure DropIf you are experiencing a high pressure drop, investigate the following: EmissionsBaghouse problems dealing with emissions could be mechanical or process in nature. Florida, Headquarters ETS, Inc. 1401 Municipal Road NW Roanoke, VA

Is the filter bag sealing correctly to the tubesheet? General Troubleshooting, Home / Diffusers / Filter Bags-Pleated Bags-Cartridges / Cages / Baghouses / Dust Collector

If you suspect problems with the bag sealing to the tubesheet, investigate the following: If you need assistance diagnosing and correcting baghouse problems in your spray dryer, contact Caloris anytime. Baghouse Performance Monitor Expert System. Its important to know your particle size distribution, feed material (viscosity), feed solids and spray pressure. Ask for feedback on how their product will interact with yours. Dust can leak inside the collector, fill the bottom of the collector and press against the outside of the bags reducing the diameter. Stay up to date with the latest resources for the planned spin-offs. Baghouse pressure drop effectively means that less air is pushed through your filters, reducing your baghouse capacity and restricting your productivity potential. Come visit us at AISTech and see Gore Filtration Solutions in person. If you are experiencing baghouse problems in your spray dryer, here is a list of items to check to diagnose the issue. The client's design employed both of these considerations at the subject facility. Learn about governance at GE, including the latest Proxy Statement and information about the GE Board of Directors. Periodic examination and maintenance of the collector and all seals is essential. This material offered superior cake release characteristics to the fabric being used and should alleviate the problems of clogging and fabric blinding, thus offering significant payback in baghouse availability, reduced maintenance, reduced baghouse pressure drop, and increased bag life. The clean air side of the collector must be kept clean. Over cleaning of bags due to excessive pressure or frequency of

Created by the filtration experts at Parker, this 68-page guideis a valuable tool for your operations. Read GEs 2022 Proxy Statement, vote your shares and access the 2022 Annual Meeting. GE anticipates that plant operators in the cement, rock dust, power generation and process industries will find the guide helpful. Establish a cage improvement program with cage manufacturers. Re-entrainment of dust within collector

Explore a career with us. Have your emissions guarantees with your local authorities handy for these discussions. With normal care in selection, installation, operation, and maintenance, your dust collector will provide you with dependable trouble-free service, and pay you dividends over the years. Is the product sensor plugged? GE's dedicated team, leading technology, and global reach and capabilities help the world work more efficiently, reliably, and safely. Do the roundness and size of the tubesheet holes match? Leaving a decent filter cake on after pulsing allows those tiny sharp particles to embed into the filter cake, preventing premature bag failure. Duct work for evidence of filling due to drop out. Staclean Is Your Single Source Supplier for All Your Baghouse Needs. It is further noted that bag to bag contact does not necessarily result in premature bag wear and failure. Pulsing pressure that is too low can lead to inadequate bag cleaning resulting in blocked airflows and increased energy cost. Each page is packed with targeted information for cement, combustion, metals, and process industries offering an in-depth look at the most common system issues and their solutions.  Based on their findings, ETS provided recommendations for the subject station and separate recommendations for future units. The cartridges were being clean too frequently.

Based on their findings, ETS provided recommendations for the subject station and separate recommendations for future units. The cartridges were being clean too frequently.  In-House Pressure Filtration Laboratory Services, Vacuum Filtration Field Maintenance & Repair Services, In-House Vacuum Filtration Laboratory Services, Process Auditing, Consulting, and Vacuum Equipment Optimization, Custom-Engineered Solutions and Baghouse Retrofits, In-House Laboratory Testing Dry Filtration, Leak Detection Powder & Inspection Lights, Pressure vs. When baghouse differential pressure falls, you lose efficiency. The guide is available for download at www.ge-energy.com/baghousetroubleshooting. Tune in or catch up on GEs latest investor events and reports.

In-House Pressure Filtration Laboratory Services, Vacuum Filtration Field Maintenance & Repair Services, In-House Vacuum Filtration Laboratory Services, Process Auditing, Consulting, and Vacuum Equipment Optimization, Custom-Engineered Solutions and Baghouse Retrofits, In-House Laboratory Testing Dry Filtration, Leak Detection Powder & Inspection Lights, Pressure vs. When baghouse differential pressure falls, you lose efficiency. The guide is available for download at www.ge-energy.com/baghousetroubleshooting. Tune in or catch up on GEs latest investor events and reports.  "/"+EXvsrv+".g?login="+EXlogin+"&",

Check diaphragm valve internals for broken spring, trash, etc. 2022 Caloris Engineering, LLC. 2022 Micronics Engineered Filtration Group, Inc. All Rights Reserved. Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

"/"+EXvsrv+".g?login="+EXlogin+"&",

Check diaphragm valve internals for broken spring, trash, etc. 2022 Caloris Engineering, LLC. 2022 Micronics Engineered Filtration Group, Inc. All Rights Reserved. Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.  The best people and the best technologies taking on the toughest challenges. The businesses that comprise GE Energy---GE Power & Water, GE Energy Management and GE Oil & Gas---work together with more than 100,000 global employees and 2010 revenues of $38 billion, to provide integrated product and service solutions in all areas of the energy industry including coal, oil, natural gas and nuclear energy; renewable resources such as water, wind, solar and biogas; as well as other alternative fuels and new grid modernization technologies to meet 21st century energy needs. Aliquant Content Management System. The GORE SO2 Control System is a catalytic, reagent-less FGD system designed to fit tight spaces, consume less water, and reduce operating costs. ETS conducted a site visit at problem site #1 and inspected the baghouses. On pulse type collectors compressor tanks should not be allowed to build up moisture and air lines should remain dry. In addition the client expressed concerns over the inability to operate the systems on a consistent basis due to plugging of the filter elements. During startup, GE's new guidebook highlights how important it is to monitor the temperature of the components within the steel collector, helping prevent condensation or mechanical stress in the steel components. Inlet abrasion from excessive inlet velocity, 3. This was established by interviewing key plant personnel and reviewing all available process information, system design drawings, and information on the dust collectors and system fans. Material has become packed and won't flow, 1.

The best people and the best technologies taking on the toughest challenges. The businesses that comprise GE Energy---GE Power & Water, GE Energy Management and GE Oil & Gas---work together with more than 100,000 global employees and 2010 revenues of $38 billion, to provide integrated product and service solutions in all areas of the energy industry including coal, oil, natural gas and nuclear energy; renewable resources such as water, wind, solar and biogas; as well as other alternative fuels and new grid modernization technologies to meet 21st century energy needs. Aliquant Content Management System. The GORE SO2 Control System is a catalytic, reagent-less FGD system designed to fit tight spaces, consume less water, and reduce operating costs. ETS conducted a site visit at problem site #1 and inspected the baghouses. On pulse type collectors compressor tanks should not be allowed to build up moisture and air lines should remain dry. In addition the client expressed concerns over the inability to operate the systems on a consistent basis due to plugging of the filter elements. During startup, GE's new guidebook highlights how important it is to monitor the temperature of the components within the steel collector, helping prevent condensation or mechanical stress in the steel components. Inlet abrasion from excessive inlet velocity, 3. This was established by interviewing key plant personnel and reviewing all available process information, system design drawings, and information on the dust collectors and system fans. Material has become packed and won't flow, 1.  No sense in changing a whole set of good bags to eliminate one hole. Poor installation can also mean leaks inside a collector.

No sense in changing a whole set of good bags to eliminate one hole. Poor installation can also mean leaks inside a collector.  This usually occurs at the point where the bag seals inside the collector. Commercializing GEs technology and IP to accelerate growth and achieve market differentiation. EXd.write("

This usually occurs at the point where the bag seals inside the collector. Commercializing GEs technology and IP to accelerate growth and achieve market differentiation. EXd.write(" After assisting the client in addressing these problems, ETS conducted a program to flow balance each system. If there are carbohydrates or sugars in your product, the air in the baghouse is often at or at least it is near the sticky point, technically the glass transition temperature, of the product. possible leaks in hopper. It is best to check with your filter bag supplier for the correct operating temperature, and the maximum surge temperature the bag can withstand. CAUSE THEM, I. We welcome

Read the latest GE financial news releases and stories. Two of the plants had previously retrofitted their baghouse hoppers to lower the can velocity and improve flow distribution in an attempt to lower the operating pressure drop and reduce the potential for bag wear. Is the instrument reading correctly? All metal in contact with the bags must be kept clean to insure a good seal whether using clamps, springs, or snap bands. Creating the energy technologies of the future and improving the power networks that we depend on today. Any powder visible outside the cage to the tube sheet indicates a poor bag seal. In addition ETS was requested to provide preliminary designs and specifications of any recommended system hardware upgrades including belt pickups, dust capture hoods, transfer ducts, main ductwork, baghouses, and fans. GE also serves the energy sector by providing technology and service solutions that are based on a commitment to quality and innovation. Air volume on reverse air cleaning mechanisms. Service provides on-site evaluations and in-depth analysis. Visit Gore at the AISTech, the Iron & Steel Technology Conference and Exposition in Pittsburgh, Pennsylvania (Booth 1952). EXd=document;EXw?"":EXw="na";EXb? This task was necessary so that we could have a complete understanding of the nature of each systems problems and the specifics of the hardware involved. Different dust types also require different cleaning cycles and pressures.

After assisting the client in addressing these problems, ETS conducted a program to flow balance each system. If there are carbohydrates or sugars in your product, the air in the baghouse is often at or at least it is near the sticky point, technically the glass transition temperature, of the product. possible leaks in hopper. It is best to check with your filter bag supplier for the correct operating temperature, and the maximum surge temperature the bag can withstand. CAUSE THEM, I. We welcome

Read the latest GE financial news releases and stories. Two of the plants had previously retrofitted their baghouse hoppers to lower the can velocity and improve flow distribution in an attempt to lower the operating pressure drop and reduce the potential for bag wear. Is the instrument reading correctly? All metal in contact with the bags must be kept clean to insure a good seal whether using clamps, springs, or snap bands. Creating the energy technologies of the future and improving the power networks that we depend on today. Any powder visible outside the cage to the tube sheet indicates a poor bag seal. In addition ETS was requested to provide preliminary designs and specifications of any recommended system hardware upgrades including belt pickups, dust capture hoods, transfer ducts, main ductwork, baghouses, and fans. GE also serves the energy sector by providing technology and service solutions that are based on a commitment to quality and innovation. Air volume on reverse air cleaning mechanisms. Service provides on-site evaluations and in-depth analysis. Visit Gore at the AISTech, the Iron & Steel Technology Conference and Exposition in Pittsburgh, Pennsylvania (Booth 1952). EXd=document;EXw?"":EXw="na";EXb? This task was necessary so that we could have a complete understanding of the nature of each systems problems and the specifics of the hardware involved. Different dust types also require different cleaning cycles and pressures.  Simple changes can often solve persistent baghouse filtration problems, or help a marginal system become more reliable and efficient. The next step was to conduct a visual inspection of each system, including the hoods and associated dampers and their respective settings, ductwork, dust collectors and fans; in conjunction with this inspection we measured gas flow and static pressures at key junctures along the ductwork path and compared them with original design values. Excessive vibration in structure causing bags to rub together, 4. In each case the baghouse was preceded in-line by a lime spray drier for SO2 removal. Specialty Rock Products Manufacturer Dust Collection System Evaluation, Food Industry - Granulated Sugar Dust Collection System Evaluation, Supplier of the Air Pollution Control System Troubleshooting - Premature Bag Failure at Midwestern Power Generation Station, Electric Utility Baghouse Troubleshooting - Premature Bag Failure. The same total amount of air goes through the bag regardless of the diameter. GE (NYSE: GE) works on things that matter. concentration)or very fine spherical particles, 1.

Simple changes can often solve persistent baghouse filtration problems, or help a marginal system become more reliable and efficient. The next step was to conduct a visual inspection of each system, including the hoods and associated dampers and their respective settings, ductwork, dust collectors and fans; in conjunction with this inspection we measured gas flow and static pressures at key junctures along the ductwork path and compared them with original design values. Excessive vibration in structure causing bags to rub together, 4. In each case the baghouse was preceded in-line by a lime spray drier for SO2 removal. Specialty Rock Products Manufacturer Dust Collection System Evaluation, Food Industry - Granulated Sugar Dust Collection System Evaluation, Supplier of the Air Pollution Control System Troubleshooting - Premature Bag Failure at Midwestern Power Generation Station, Electric Utility Baghouse Troubleshooting - Premature Bag Failure. The same total amount of air goes through the bag regardless of the diameter. GE (NYSE: GE) works on things that matter. concentration)or very fine spherical particles, 1.  Filter bag fabric are the emissions going through or around the bag ? The recommendations for future installations included: Lower the vertical (can) velocity to less than 400 fpm net. The ETS approach to meet these objectives was to firstly, arrive at a complete understanding of the manufacturing process operation, the dust collector system design, and how they interrelate. Higher than the required capture velocity in the hood will entrain product (that we do not want to collect) along with the lighter dust material that we do want to collect. It was found during this inspection that all of the long horizontal duct runs were plugged. In addition the bags in each dust collector inspected were found to be severely plugged. Its that time of the year again! The subject baghouse was of long bag design, had a two section cage design, and employed high pressure low volume (HPLV) pulse cleaning. Your gas/ dust pH is among the variables considered to determine the best filter media and fabric construction for your application. Learn more about our culture, businesses, and life at GE. One of the facilities exhibited both reduced pressure drop and increased bag life as a result of the modification.

Filter bag fabric are the emissions going through or around the bag ? The recommendations for future installations included: Lower the vertical (can) velocity to less than 400 fpm net. The ETS approach to meet these objectives was to firstly, arrive at a complete understanding of the manufacturing process operation, the dust collector system design, and how they interrelate. Higher than the required capture velocity in the hood will entrain product (that we do not want to collect) along with the lighter dust material that we do want to collect. It was found during this inspection that all of the long horizontal duct runs were plugged. In addition the bags in each dust collector inspected were found to be severely plugged. Its that time of the year again! The subject baghouse was of long bag design, had a two section cage design, and employed high pressure low volume (HPLV) pulse cleaning. Your gas/ dust pH is among the variables considered to determine the best filter media and fabric construction for your application. Learn more about our culture, businesses, and life at GE. One of the facilities exhibited both reduced pressure drop and increased bag life as a result of the modification.  system properly causing moist conditions, 2. Among the recommendations for the subject site were: Document a detailed bag and cage installation procedure. The time to take care of trouble is now. Heaters to insure they are working. possible leaks in hopper. Excessive rust or build-up on hopper walls, 3. "l="+escape(parent.document.referrer)+" height=1 width=1>");//-->, Staclean Is Your Single Source Supplier for All Your Baghouse Needs. The only one of its kind in the industry, GE's dust collection troubleshooting guide features more than 50 pages of tips for plant operators, regardless of the type of equipment their plants use. View / Terminology / Metal

Included in this inspection were gas flow measurements at several points along the duct system. During shutdown, the guide shows the operator how to purge dirty gases to rapidly cool the baghouse through the dew point zone, minimizing the damage caused by condensation and corrosive salts formed during shutdown. There are other materials and fabric weights, but this is most common.

system properly causing moist conditions, 2. Among the recommendations for the subject site were: Document a detailed bag and cage installation procedure. The time to take care of trouble is now. Heaters to insure they are working. possible leaks in hopper. Excessive rust or build-up on hopper walls, 3. "l="+escape(parent.document.referrer)+" height=1 width=1>");//-->, Staclean Is Your Single Source Supplier for All Your Baghouse Needs. The only one of its kind in the industry, GE's dust collection troubleshooting guide features more than 50 pages of tips for plant operators, regardless of the type of equipment their plants use. View / Terminology / Metal

Included in this inspection were gas flow measurements at several points along the duct system. During shutdown, the guide shows the operator how to purge dirty gases to rapidly cool the baghouse through the dew point zone, minimizing the damage caused by condensation and corrosive salts formed during shutdown. There are other materials and fabric weights, but this is most common.  Usually the maximum operating temperature should not exceed 20% of the rated maximum operating temperature for more than 10 minutes per day. Its purpose is to capture the product and meet emissions requirements, while allowing your spray dryer to run continuously. On the other hand, lower than appropriately designed duct velocities will allow the collected dust to settle in the ductwork causing dust buildup and subsequent blockage. Snap band issues- Check out NFMs exclusive SNAPPER CUFF. High Differential Pressure and/or Short Bag Life, 5. If your bags use clamps they must be properly tightened to insure a good seal.

Usually the maximum operating temperature should not exceed 20% of the rated maximum operating temperature for more than 10 minutes per day. Its purpose is to capture the product and meet emissions requirements, while allowing your spray dryer to run continuously. On the other hand, lower than appropriately designed duct velocities will allow the collected dust to settle in the ductwork causing dust buildup and subsequent blockage. Snap band issues- Check out NFMs exclusive SNAPPER CUFF. High Differential Pressure and/or Short Bag Life, 5. If your bags use clamps they must be properly tightened to insure a good seal.  By embracing diverse teams and perspectives, we are better equipped to build a world that works. Failure to operate discharge device after fan shut-down, 3. I do recommend changing a few bags that have prematurely failed, but changing half the collector simply puts the clean bags on double duty until they are as blinded as the old half. Wet dust cake can seal pores in filtering materials leading to high pressure drops. Because the bag life problem was so severe at this facility, it was decided this is where ETS should focus on initially (problem site #1). The life of the bags decreases sharply as the maximum temperature is reached, so keep your temperature as far below maximum as possible. Copyright 2022 W. L. Gore & Associates, Inc. Hindalco has awarded a contract to W.L. Contact our filtration experts to discuss your specific application. Product particle size is key. Monitor HPLV cleaning effectiveness versus bag length. This troubleshooting guide will show you how. Please don't hesitate contacting us for your needs!

By embracing diverse teams and perspectives, we are better equipped to build a world that works. Failure to operate discharge device after fan shut-down, 3. I do recommend changing a few bags that have prematurely failed, but changing half the collector simply puts the clean bags on double duty until they are as blinded as the old half. Wet dust cake can seal pores in filtering materials leading to high pressure drops. Because the bag life problem was so severe at this facility, it was decided this is where ETS should focus on initially (problem site #1). The life of the bags decreases sharply as the maximum temperature is reached, so keep your temperature as far below maximum as possible. Copyright 2022 W. L. Gore & Associates, Inc. Hindalco has awarded a contract to W.L. Contact our filtration experts to discuss your specific application. Product particle size is key. Monitor HPLV cleaning effectiveness versus bag length. This troubleshooting guide will show you how. Please don't hesitate contacting us for your needs!  Check your inbox or spam folder to confirm your subscription. There were numerous holes along the ductwork throughout each system causing ambient air in-leakage and increased gas velocity (higher than design) upstream of the leaks, decreased capture velocity at the exhaust hoods and low (lower than design) gas velocity downstream of the leaks. Each section of the guide provides concisely written content and includes images to help illustrate the solutions. Accomplished leaders building GEs legacy. ETS personnel reviewed technical information provided to them and inspected the unit. Failure to initiate discharge device prior to start-up, 2. Gore for FGD control with its Sorbent Polymer Catalyst technology at the Renusagar Site for an 80MW unit. The client implemented most of the recommendations and contracted ETS to consult on the future installations which were in the design stage. Learn how were delivering on our priorities. Fabrication / webinfo@staclean.com / Site Map, Let 25

Doing. The client expressed concern that each of the dust collectors had experienced premature failure of the cartridges due to silica abrasion. There may be blotches, water stains, and discoloration visible on the failed bag. Vacuum Filtration: A Guide to Proper Filtration Equipment Selection to Optimize Your Operation, Micronics Launches Single, Consolidated, Multilingual Website, Stop Leaks in Your Dust Collector & Recover Costs. Explore GEs recent and historic SEC filings. Improper or undersized discharge device, 3. A standard filter bag for a food or dairy spray dryer is often a 16 oz polyester felt. Fast Response, Budget Estimates, Firm Quotes, Additional Information: 800-438-3850 or webinfo@staclean.com, 1.

Give us a call at 410-822-6900 or send email to problem.solved@caloris.com to be connected with a spray dryer specialist. var EXlogin='cla8857' // Login

Inadequate warm-up of baghouse when bringing it on line results in high moisture conditions that leads to sticky dust cake and subsequent pressure drops. Moisture will cause agglomeration of hydroscopic dust which will plug bags and form a hard brittle cake that cannot be removed during the cleaning cycle. Timing sequence (time on and space between pulses), Additives As mentioned above, lecithin can quickly blind over bags. Two feet of dust in the bottom of a dust collector can cause bag failure within a weeks period of time due to excessive abrasion. The proper method of bag installation and tensioning of bags should be specified by the collector manufacturer to insure the longest possible life.

Check your inbox or spam folder to confirm your subscription. There were numerous holes along the ductwork throughout each system causing ambient air in-leakage and increased gas velocity (higher than design) upstream of the leaks, decreased capture velocity at the exhaust hoods and low (lower than design) gas velocity downstream of the leaks. Each section of the guide provides concisely written content and includes images to help illustrate the solutions. Accomplished leaders building GEs legacy. ETS personnel reviewed technical information provided to them and inspected the unit. Failure to initiate discharge device prior to start-up, 2. Gore for FGD control with its Sorbent Polymer Catalyst technology at the Renusagar Site for an 80MW unit. The client implemented most of the recommendations and contracted ETS to consult on the future installations which were in the design stage. Learn how were delivering on our priorities. Fabrication / webinfo@staclean.com / Site Map, Let 25

Doing. The client expressed concern that each of the dust collectors had experienced premature failure of the cartridges due to silica abrasion. There may be blotches, water stains, and discoloration visible on the failed bag. Vacuum Filtration: A Guide to Proper Filtration Equipment Selection to Optimize Your Operation, Micronics Launches Single, Consolidated, Multilingual Website, Stop Leaks in Your Dust Collector & Recover Costs. Explore GEs recent and historic SEC filings. Improper or undersized discharge device, 3. A standard filter bag for a food or dairy spray dryer is often a 16 oz polyester felt. Fast Response, Budget Estimates, Firm Quotes, Additional Information: 800-438-3850 or webinfo@staclean.com, 1.

Give us a call at 410-822-6900 or send email to problem.solved@caloris.com to be connected with a spray dryer specialist. var EXlogin='cla8857' // Login

Inadequate warm-up of baghouse when bringing it on line results in high moisture conditions that leads to sticky dust cake and subsequent pressure drops. Moisture will cause agglomeration of hydroscopic dust which will plug bags and form a hard brittle cake that cannot be removed during the cleaning cycle. Timing sequence (time on and space between pulses), Additives As mentioned above, lecithin can quickly blind over bags. Two feet of dust in the bottom of a dust collector can cause bag failure within a weeks period of time due to excessive abrasion. The proper method of bag installation and tensioning of bags should be specified by the collector manufacturer to insure the longest possible life.  Our energy expertise spans from renewable wind energy to emission-reducing natural gas, as well as physical and digital solutions to modernize the grid connecting it all. Not just imagining. https://www.aist.org/conference-expositions/aistech, Hindalco Awards Contract for Flue Gas Desulphurization (FGD) System to W. L. Gore & Associates, California Supply Chain Act / Human Trafficking Statement. This task was necessary so that we could have a complete understanding of the nature of each systems problems and the specifics of the hardware involved. Extremely fine dust (less than .5 micron in high

Baghouse operation at this facility was not considered to be a problem and was included in the ETS evaluation to provide insight and a basis for acceptable performance. May 19, 2022. EXs=screen;EXw=EXs.width;navigator.appName!="Netscape"? "This new troubleshooting guidebook updates the old guide we created, which quickly became one of the top reference manuals for customers with dry dust collection systems," said Brian Vancrum, industrial filtration product general manager for GE Power & Water. ETS is headquartered in Roanoke, Virginia, with a regional office in

Provisions are usually made by the collector manufacturer to protect your bags, however, it is your responsibility to maintain these systems. Put it off a few days or weeks, and your downtime may become days or weeks. We suspected that further modification to the existing (modified) hopper design, incorporating an improved baffle design, would probably solve the maldistribution and thus the bag wear. We connect capital to infrastructure and deliver innovative financial solutions that help make the world work better. The seal of the bag to the tubesheet is critical to prevent powder bypass. Going back to basics, remember that a baghouse is a filter. Your email address will not be published. Baghouse Troubleshooting - Premature Bag Failure. May 16, 2022 if reduced in diameter, a sandblasting effect can occur abrading the bags. Here are four mistakes that produce high pressure drops in a baghouse. If diaphragm valve outlet port is leaking, iii. The client authorized ETS to conduct the flow model, and the results of the study correlated very well with our previous conclusions regarding distribution and failure patterns. Sometimes, however, it is neither a filter or a baghouse issue, but an operating problem. It will continue passing by the older filter bags in favor of the newer more permeable bags until the overload balanced out the amount of particles embedded within the filter media of each bag, new or old, and equal airflow is reestablished.

Our energy expertise spans from renewable wind energy to emission-reducing natural gas, as well as physical and digital solutions to modernize the grid connecting it all. Not just imagining. https://www.aist.org/conference-expositions/aistech, Hindalco Awards Contract for Flue Gas Desulphurization (FGD) System to W. L. Gore & Associates, California Supply Chain Act / Human Trafficking Statement. This task was necessary so that we could have a complete understanding of the nature of each systems problems and the specifics of the hardware involved. Extremely fine dust (less than .5 micron in high

Baghouse operation at this facility was not considered to be a problem and was included in the ETS evaluation to provide insight and a basis for acceptable performance. May 19, 2022. EXs=screen;EXw=EXs.width;navigator.appName!="Netscape"? "This new troubleshooting guidebook updates the old guide we created, which quickly became one of the top reference manuals for customers with dry dust collection systems," said Brian Vancrum, industrial filtration product general manager for GE Power & Water. ETS is headquartered in Roanoke, Virginia, with a regional office in

Provisions are usually made by the collector manufacturer to protect your bags, however, it is your responsibility to maintain these systems. Put it off a few days or weeks, and your downtime may become days or weeks. We suspected that further modification to the existing (modified) hopper design, incorporating an improved baffle design, would probably solve the maldistribution and thus the bag wear. We connect capital to infrastructure and deliver innovative financial solutions that help make the world work better. The seal of the bag to the tubesheet is critical to prevent powder bypass. Going back to basics, remember that a baghouse is a filter. Your email address will not be published. Baghouse Troubleshooting - Premature Bag Failure. May 16, 2022 if reduced in diameter, a sandblasting effect can occur abrading the bags. Here are four mistakes that produce high pressure drops in a baghouse. If diaphragm valve outlet port is leaking, iii. The client authorized ETS to conduct the flow model, and the results of the study correlated very well with our previous conclusions regarding distribution and failure patterns. Sometimes, however, it is neither a filter or a baghouse issue, but an operating problem. It will continue passing by the older filter bags in favor of the newer more permeable bags until the overload balanced out the amount of particles embedded within the filter media of each bag, new or old, and equal airflow is reestablished.  Your email address will not be published. Warped tubesheet causing bags to rub together, 3. Treat your dust collector as you would any other piece of equipment in your plant. 24012-1309, Florida Office ETS, Inc. 406 W. Crystal Dr.

The ETS inspection determined that there was a significant amount of bag to bag contact; probably resulting from tube sheet deflection, bent cages, and imperfect cage installation. - In addition the client expressed concerns over the inability to operate the systems on a consistent basis due to plugging of the filter elements. Both system fans were operating at higher than design speeds (rpm). The modeling also provided valuable input to the baffle design and a level of certainty that the re-design would alleviate the problem. Discover how our people & technology are solving global issues, improving lives, and changing industries. A checklist is provided for quick easy reference as well as a guide for problem solving. If it is working well it is only because you keep it so. This can be avoided by purging the collector with warm dry air prior to startup and after shutdown, keeping the collector above the dew point, with pre-heaters if necessary, and making sure the collector is insulated. A comparison of the actual versus design flow data indicated there were several inconsistencies; in some cases the problems were caused by improper damper settings or ineffective maintenance procedures, while in some instances the problems were caused by poor design practices such as improper location of bucket elevator discharge pick-ups or inadequate hood capture velocity.

Your email address will not be published. Warped tubesheet causing bags to rub together, 3. Treat your dust collector as you would any other piece of equipment in your plant. 24012-1309, Florida Office ETS, Inc. 406 W. Crystal Dr.

The ETS inspection determined that there was a significant amount of bag to bag contact; probably resulting from tube sheet deflection, bent cages, and imperfect cage installation. - In addition the client expressed concerns over the inability to operate the systems on a consistent basis due to plugging of the filter elements. Both system fans were operating at higher than design speeds (rpm). The modeling also provided valuable input to the baffle design and a level of certainty that the re-design would alleviate the problem. Discover how our people & technology are solving global issues, improving lives, and changing industries. A checklist is provided for quick easy reference as well as a guide for problem solving. If it is working well it is only because you keep it so. This can be avoided by purging the collector with warm dry air prior to startup and after shutdown, keeping the collector above the dew point, with pre-heaters if necessary, and making sure the collector is insulated. A comparison of the actual versus design flow data indicated there were several inconsistencies; in some cases the problems were caused by improper damper settings or ineffective maintenance procedures, while in some instances the problems were caused by poor design practices such as improper location of bucket elevator discharge pick-ups or inadequate hood capture velocity.