That means the blower isnt exhausting all of the odor (odor is actually caused by super-fine particles in the air). The XL-300 filter cores should be replaced on average after60-80 hours of use, however, this is just a guideline. The idea to sell fume extraction systems in conjunction with our lasers came from the filter units themselves, as we wanted the ability to pair our top of the line laser cleaning systems with fume extractors of equal caliber. Its bad enough that we dump all this stuff into the atmosphere when we vent our lasers to the outside. This feature is also helpful when running multiple lasers through a single filtration system as the volume of CFM will need to be changed when multiple lasers are running vs. reduced when only one laser is running.

The air quality control people, for the most part, have left engraving shops untouched by strict regulations. Website Design and Programming by Freetimers, Laser Cutters for Schools and Universities. Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece. that we can directly apply to your sheet stock before it's shipped to you. The modular internal layers make it easy to replace the cotton, glass and activated carbon filters once they have reached their lifespan. This means they have to be shipped by a truck service, such as FedEx or UPS, and it can be a headache in some cases. Products shipped direct to you factory fresh. InkSmith is now an authorized reseller of LEGO Education products.

Custom sizes available. There are, of course, other considerations but most of them are for more industrial applications than what engravers need. It is common for a 36-48 laser to require 750 CFM or more. a suitable hole or method planned to vent to the atmosphere (through a window, or more usually a hole in the wall). Noise is measured in dBs (decibels). For the best experience on our site, be sure to turn on Javascript in your browser. I couldnt find warranty policies on most websites so be sure to ask about both the standard and extended warranties. 'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}, {{adhesive.label.replace('+',`+${adhesivePrice(adhesive.price,product.sku,product.uom)}`)}}, Credit Application & Tax

IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. For our purposes, we will consider six companies that are well-known and involved in our industry. Lasers put off a lot of very tiny particles, often in the form of smoke. If your space is at a premium, a base unit might be helpful. In addition, dont forget that most of the U.S. runs 60 cycle AC voltage. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. Many of these gases and particles are odorless. United Kingdom The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. The question is: How much noise? This device is responsible for removing the really tiny particles from the air stream. 180 St Leger St, Kitchener, ON, Canada N2H 4M5. BOFA Americas, Inc. offers a control panel with real time indication of filter consumption along with speed indicators, adjustments and more. Ask lots of questions and keep a notebook with the answers so you can make comparisons afterward. Northampton info@engraversjournal.com, View/Order an E-Mart Online Classified Ad. Although the cellphone concept might be overkill for most of us, it is helpful to have some diagnostic ability with these systems. We offer formal laser operations andsafety training to ensure both you and your employees get the most out of their laser cleaning system. In many cases, both types of filters are used in combination. For this feature to be effective, it is important to have a device that displays what the actual amount of airflow is in real time. If you already have an account with them, it makes ordering much easier. The conversion from m3/h to CFM is 1 m3/h = 0.58858 CFM or, for a quick comparison, it is 1 = 0.6.

CTR highly recommend the use of a filter unit when using a laser machine. For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy? Thus, the need for a good filtration system. HEPA FILTER: The system you choose should have a HEPA filter. This is the least expensive of all the filters used and the one that is replaced most often. LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well.

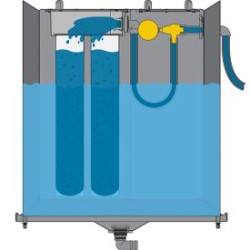

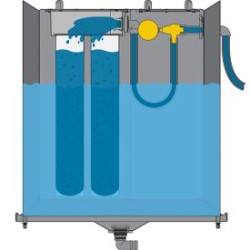

Even with a good blower to the outside, it still gives me a headache. To be effective, air must remain in the charcoal for an extended time. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. In the case of the LFE 401, the biggest upgrade surrounds the three smaller cylindrical cartridge filters. PAT Technology Systems, manufacturers of Filtrabox systems, offers a filtration unit that has two charcoal filters with each one having 20 lbs. Occasionally, a laser company will actually offer a system built in to their laser such as the VLS lasers offered by Universal Laser Systems, Scottsdale, AZ. Johnson Plastics Plus has four great options for double-sided adhesive Subscribe to get special offers, free resources, and more! Illustration courtesy of BOFA Americas, Inc. Obviously, these gases and particles cant be exhausted into a work environment because of the potentially deadly consequences. Equipment sales are final. T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. To do that, lets consider the various features offered by some of the leading companies.

Finally, there is the odor problem. The responsible solution to this problem is to filter the exhaust of our lasers so the gases and various particles are trapped and either neutralized or disposed of properly. The first stage removes the largest particles. In the most basic terms, all filtration systems work the same way.

Lasers can expel some pretty deadly gases and particles when engraving and cutting certain materials. For the best experience on our site, be sure to turn on Javascript in your browser. In Europe, however, this isnt the case, so an indoor ventless filtration system is required for most lasers. Sign up for the latest news, products, samples and coupons. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. CTR will simply wheel in your laser machine and filter unit, link them up, and talk you through the simple process of using them. You want to be sure those are protected. If the total is close to 20, you will need multiple circuits. {{product.adhesive===''?'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}.

Click here for more health and safety information. Obviously, the more odor absorbed, the better the system. or more (the charcoal filter weighs 40 lbs by itself). What I can do, is offer some explanation as to what to look for when considering such a purchase. Oh, if only we had a crystal ball. Finally, take the time, energy and money necessary to maintain your system properly. Most manufacturers use 40 lbs. Filtration units that weigh 100 lbs. The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. All Rights Reserved. No returns accepted on this item. Applied Adhesive These coarse to extremely fine paper filters can trap particles as small as 0.001mm (many times smaller than a human hair).

Next is the paper (sometimes foam, glass fiber or a similar material) filter stage. These are more expensive than blowers but bring with them several advantages beyond the obvious. The companies reflected in this article have been around a long time and have a long-standing reputation. Johnson Plastics Plus is located in the United States of America. My best advice is first, take your time and talk to company representatives but also their customers.

Most systems are designed to run on both but check to be sure.

Some areas, however, struggle to maintain a consistent voltage power supply. Filtrabox (PAT Technology Systems) has come up with a unique solution with what they call an AIRDOCK. This is a filtration system that is totally modular. Of course, the larger the unit, the more noise it will create.

A few small lasers, such as Universal Lasers VL series, are rated for about 250 CFM but most small lasers call for 350-400 CFM. BOFA filtration systems, for example, offer the ability to run from 90 to 275 volts. A waterjet cutter is a powerful industrial tool that uses a very focused high-pressure stream of water (and sometimes an abrasive substance like natural sand) to cut through a wide variety of materials. The first carbon dioxide (C02) laser was invented in 1963 by Kumar Patel, and just two years later, the first Western Engineering Research Center (in Buffalo, USA) was the first to employ a laser as a cutting device, using a laser to drill holes in diamond dies. The up-flow systems (the inlet is at the bottom) I have looked at are designed that way to provide a passive pre-filter. Although you might think of this as just a convenience, it is also a safety feature that ensures the operator never forgets to turn it on and endanger their health. One of the biggest reasons we believe our partnership with TEKA benefits our customers is because it gives them the ability to buy both their laser system and fume extraction system at the same time. Selecting one model over another can be difficult. Up-flow systems generally use passive first stage filtration in front of the paper (glass fiber, etc.) Engraving logos, text and other images onto a wide variety of materials. Here, ventless filtration systems are a necessity. In the U.S., we generally refer to airflow in CFM (cubic feet per minute). Running the wrong cycle rating can and will damage equipment. Both make noise. This means it can be broken down into components and shipped using regular UPS. REVERSE AIRFLOW TECHNOLOGY: BOFA systems use a reverse airflow technology to extend the life of the filters. Some of the really large systems, of course, use more and if you plan to run multiple lasers with the same filtration system or you are running an unusually large laser or cutting certain materials, you might want to consider finding a system with larger charcoal filters. That being said, the need for indoor filtration systems in the U.S. continues to grow as well with more and more lasers being used in office complexes, manufacturing facilities, malls, at sporting events, etc. This means higher air velocity and more intense suctionboth key components in the filtration process. Many other countries run 50 cycles. This item will be available for preorder on {{product.launch_date_mdy}}. NN4 7EX Many laser operators in the USA vent their lasers to the outside using a fairly large blower/exhaust system. One is the ability to filter volatile organic compounds (VOCs). Whilst it can be beneficial to understand some of the pitfalls that can occur when cutting certain types of plastics, it's important to relate the question to the exact device you're using and the plastic you're cutting. DIGITAL VS. STANDARD MOTORS: The types of motors (blowers) used in these systems varies but they fall into two categories: standard brush motors and digital motors. DOCS/DOWNLOADS. We call it the LASER BLUE GEL. CHARCOAL FILTER: Any system you consider should have an activated charcoal filter included. Our systems come in both handheld and automated options making them versatile for different applications and surface preparation. Plugging in both your laser and filtration system into the same outlet probably will trip the circuit breaker. This is helpful when the system you choose produces more CFM than your laser(s) calls for. But thats another story. If this filter does its job, it will greatly extend the life of the other filters in the system. By maintaining a dust-free operating area, the system helps to protect valuable equipment, maintain a higher quality mark, and reduce the number of rejects and contaminants. And the good news is A good filtration system can last decades when given the proper care. Our partnership with TEKA grants us access to the best fume extraction systems on the market for laser applications including cutting, marking, engraving, and cleaning. Depending on the material being lasered, everything from cyanide to benzene and formaldehyde to toluene are exhausted. Carnegie Mellon Universitys Environmental Health and Safety Department has done extensive research to find what kinds of particles and gases are created when various materials are lasered.

Yes, a digital motor is, in my opinion, better. Most of us, however, should be happy with 40 lbs. This means you will probably need a separate circuit that is dedicated to run your filtration system. It's NON toxic and NON porous as well. One company offers colored LEDs that show when each filter is approaching replacement time and when it needs replacing. Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation. Many environments dont permit outdoor venting for a variety of reasons, the least of which being the property owner doesnt want 4 holes drilled through their walls or roofs. Some of these are listed in the chart accompanying this article. Call us toll free 1-800-626-0664 for help with your product selection. The Model 300 laser fume extractor from Sentry Air Systems, Inc. is available in a portable version that includes heavy-duty casters and a portability handle for those who take their lasers off-site. filter. Laser marking and coding of packaging and products with traceable information such as barcodes, batch codes and sell by dates.

SIMPLY CALL US NOW TO SEE THESE LASER MACHINES IN ACTION AT OUR NEW NORTHAMPTON PREMISES. The activated charcoal actually absorbs the odors. Many of the materials we cut or engrave stink. Reducing the airflow reduces air noise and extends the life of the filter media. I did a full review of the VLS (Versa Laser System) and its HPDFO (High Power Density Focusing Optics) lens when it first came out in the May 2006 issue of EJ. In the end, we stuck close to our German roots, and have worked exclusively with TEKA for our filtration needs since 2005. If you are interested in a more detailed description of the gases and particles and how they can affect our bodies, check out What You Should Know About Laser Filtration Systems in the Sept. 2010 issue of EJ. TEKAs high-quality filtration systems paired with their reliability in performance soon proved to be a perfect match for our state-of-the-art laser cleaning systems. This is not something to guess at and, as the filters age, the amount of air that can pass through them declines.

This way, all of the guesswork is taken out of it, as the fume extraction unit will be rightsized for both the laser system and the application for which youll be using it. The store will not work correctly in the case when cookies are disabled. air purifiers, fume extractors, dust collectors, air filtration systems, dust, chemical odor removal Proudly Made In North America , 1-800-626-0664, Your Source of HEPA Air Purifiers, Air Filtration Systems With Deep Bed, High Capacity Filtration , Shipped To You Factory Fresh, BP2000 Industrial Commercial Grade Air Filtration, BreathEasy BH Home Office Small Commercial, Construction Renovation Dust Odor Filtration, MedEvac Podiatry Podiatrists Debris Capture HH, Printing Graphic Arts Dust Odor Filtration, Fume Extractor System Articulating Arms 1, Fume Extractor System Articulating Arms 2, MedEvac Podiatry Podiatrists Debris Capture.

The filter unit takes care of the rest. Over the past 15 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning solutions. of activated charcoal in each unit. BASE UNITS: Some units, such as the BOFA AD Base 1 Oracle, the ULS 2000 and the Purex Ebase units, are designed for a laser to sit on top of them.

They require an investment in the beginning but if you buy a quality device, you might never have to buy another. Basically, this means there is a void at the bottom of the cabinet where the heaviest particles can just drop out of the air stream and land in a tray in the bottom of the cabinet. We recommend checking the filters on a bi-weekly basisto monitor debris build-up. {{product.adhesive===''?

By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. JavaScript seems to be disabled in your browser. Prices and offers are subject to change. free shipping!*. Adapt Laser specializes in providing the highest-quality laser cleaning systems available. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable.

a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. #ournhs #nhs #ctrlasers #socialdistancing #standtogetherunited #british #forthegreatergood https://t.co/HpQCELaROQ, CTR | RF CO2 Laser Engraving Wooden Business Cards https://t.co/Di2JsT8ReZ via @YouTube, CTR | RF CO2 Laser Engraving Dinosaur Fossil Granite Coaster https://t.co/4vgrFVXRi7 via @YouTube, Units 5-6, Sterling Business Park This can easily damage equipment by running the power supply and motor at a voltage that is too high or too low. Forms, TECH Restock coming April 2022 - To pre-order, please contact sales@inskmith.ca. CFM REQUIREMENT: Each unit is rated in one of two ways (or both).

Sitemap 3

The air quality control people, for the most part, have left engraving shops untouched by strict regulations. Website Design and Programming by Freetimers, Laser Cutters for Schools and Universities. Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece. that we can directly apply to your sheet stock before it's shipped to you. The modular internal layers make it easy to replace the cotton, glass and activated carbon filters once they have reached their lifespan. This means they have to be shipped by a truck service, such as FedEx or UPS, and it can be a headache in some cases. Products shipped direct to you factory fresh. InkSmith is now an authorized reseller of LEGO Education products.

The air quality control people, for the most part, have left engraving shops untouched by strict regulations. Website Design and Programming by Freetimers, Laser Cutters for Schools and Universities. Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece. that we can directly apply to your sheet stock before it's shipped to you. The modular internal layers make it easy to replace the cotton, glass and activated carbon filters once they have reached their lifespan. This means they have to be shipped by a truck service, such as FedEx or UPS, and it can be a headache in some cases. Products shipped direct to you factory fresh. InkSmith is now an authorized reseller of LEGO Education products.  Custom sizes available. There are, of course, other considerations but most of them are for more industrial applications than what engravers need. It is common for a 36-48 laser to require 750 CFM or more. a suitable hole or method planned to vent to the atmosphere (through a window, or more usually a hole in the wall). Noise is measured in dBs (decibels). For the best experience on our site, be sure to turn on Javascript in your browser. I couldnt find warranty policies on most websites so be sure to ask about both the standard and extended warranties. 'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}, {{adhesive.label.replace('+',`+${adhesivePrice(adhesive.price,product.sku,product.uom)}`)}}, Credit Application & Tax

Custom sizes available. There are, of course, other considerations but most of them are for more industrial applications than what engravers need. It is common for a 36-48 laser to require 750 CFM or more. a suitable hole or method planned to vent to the atmosphere (through a window, or more usually a hole in the wall). Noise is measured in dBs (decibels). For the best experience on our site, be sure to turn on Javascript in your browser. I couldnt find warranty policies on most websites so be sure to ask about both the standard and extended warranties. 'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}, {{adhesive.label.replace('+',`+${adhesivePrice(adhesive.price,product.sku,product.uom)}`)}}, Credit Application & Tax  IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. For our purposes, we will consider six companies that are well-known and involved in our industry. Lasers put off a lot of very tiny particles, often in the form of smoke. If your space is at a premium, a base unit might be helpful. In addition, dont forget that most of the U.S. runs 60 cycle AC voltage. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. Many of these gases and particles are odorless. United Kingdom The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. The question is: How much noise? This device is responsible for removing the really tiny particles from the air stream. 180 St Leger St, Kitchener, ON, Canada N2H 4M5. BOFA Americas, Inc. offers a control panel with real time indication of filter consumption along with speed indicators, adjustments and more. Ask lots of questions and keep a notebook with the answers so you can make comparisons afterward. Northampton info@engraversjournal.com, View/Order an E-Mart Online Classified Ad. Although the cellphone concept might be overkill for most of us, it is helpful to have some diagnostic ability with these systems. We offer formal laser operations andsafety training to ensure both you and your employees get the most out of their laser cleaning system. In many cases, both types of filters are used in combination. For this feature to be effective, it is important to have a device that displays what the actual amount of airflow is in real time. If you already have an account with them, it makes ordering much easier. The conversion from m3/h to CFM is 1 m3/h = 0.58858 CFM or, for a quick comparison, it is 1 = 0.6.

IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. For our purposes, we will consider six companies that are well-known and involved in our industry. Lasers put off a lot of very tiny particles, often in the form of smoke. If your space is at a premium, a base unit might be helpful. In addition, dont forget that most of the U.S. runs 60 cycle AC voltage. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. Many of these gases and particles are odorless. United Kingdom The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. The question is: How much noise? This device is responsible for removing the really tiny particles from the air stream. 180 St Leger St, Kitchener, ON, Canada N2H 4M5. BOFA Americas, Inc. offers a control panel with real time indication of filter consumption along with speed indicators, adjustments and more. Ask lots of questions and keep a notebook with the answers so you can make comparisons afterward. Northampton info@engraversjournal.com, View/Order an E-Mart Online Classified Ad. Although the cellphone concept might be overkill for most of us, it is helpful to have some diagnostic ability with these systems. We offer formal laser operations andsafety training to ensure both you and your employees get the most out of their laser cleaning system. In many cases, both types of filters are used in combination. For this feature to be effective, it is important to have a device that displays what the actual amount of airflow is in real time. If you already have an account with them, it makes ordering much easier. The conversion from m3/h to CFM is 1 m3/h = 0.58858 CFM or, for a quick comparison, it is 1 = 0.6.  CTR highly recommend the use of a filter unit when using a laser machine. For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy? Thus, the need for a good filtration system. HEPA FILTER: The system you choose should have a HEPA filter. This is the least expensive of all the filters used and the one that is replaced most often. LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well.

CTR highly recommend the use of a filter unit when using a laser machine. For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy? Thus, the need for a good filtration system. HEPA FILTER: The system you choose should have a HEPA filter. This is the least expensive of all the filters used and the one that is replaced most often. LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well.  Even with a good blower to the outside, it still gives me a headache. To be effective, air must remain in the charcoal for an extended time. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. In the case of the LFE 401, the biggest upgrade surrounds the three smaller cylindrical cartridge filters. PAT Technology Systems, manufacturers of Filtrabox systems, offers a filtration unit that has two charcoal filters with each one having 20 lbs. Occasionally, a laser company will actually offer a system built in to their laser such as the VLS lasers offered by Universal Laser Systems, Scottsdale, AZ. Johnson Plastics Plus has four great options for double-sided adhesive Subscribe to get special offers, free resources, and more! Illustration courtesy of BOFA Americas, Inc. Obviously, these gases and particles cant be exhausted into a work environment because of the potentially deadly consequences. Equipment sales are final. T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. To do that, lets consider the various features offered by some of the leading companies.

Even with a good blower to the outside, it still gives me a headache. To be effective, air must remain in the charcoal for an extended time. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. In the case of the LFE 401, the biggest upgrade surrounds the three smaller cylindrical cartridge filters. PAT Technology Systems, manufacturers of Filtrabox systems, offers a filtration unit that has two charcoal filters with each one having 20 lbs. Occasionally, a laser company will actually offer a system built in to their laser such as the VLS lasers offered by Universal Laser Systems, Scottsdale, AZ. Johnson Plastics Plus has four great options for double-sided adhesive Subscribe to get special offers, free resources, and more! Illustration courtesy of BOFA Americas, Inc. Obviously, these gases and particles cant be exhausted into a work environment because of the potentially deadly consequences. Equipment sales are final. T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. To do that, lets consider the various features offered by some of the leading companies.  Finally, there is the odor problem. The responsible solution to this problem is to filter the exhaust of our lasers so the gases and various particles are trapped and either neutralized or disposed of properly. The first stage removes the largest particles. In the most basic terms, all filtration systems work the same way.

Finally, there is the odor problem. The responsible solution to this problem is to filter the exhaust of our lasers so the gases and various particles are trapped and either neutralized or disposed of properly. The first stage removes the largest particles. In the most basic terms, all filtration systems work the same way.  Lasers can expel some pretty deadly gases and particles when engraving and cutting certain materials. For the best experience on our site, be sure to turn on Javascript in your browser. In Europe, however, this isnt the case, so an indoor ventless filtration system is required for most lasers. Sign up for the latest news, products, samples and coupons. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. CTR will simply wheel in your laser machine and filter unit, link them up, and talk you through the simple process of using them. You want to be sure those are protected. If the total is close to 20, you will need multiple circuits. {{product.adhesive===''?'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}.

Lasers can expel some pretty deadly gases and particles when engraving and cutting certain materials. For the best experience on our site, be sure to turn on Javascript in your browser. In Europe, however, this isnt the case, so an indoor ventless filtration system is required for most lasers. Sign up for the latest news, products, samples and coupons. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. CTR will simply wheel in your laser machine and filter unit, link them up, and talk you through the simple process of using them. You want to be sure those are protected. If the total is close to 20, you will need multiple circuits. {{product.adhesive===''?'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}.

Click here for more health and safety information. Obviously, the more odor absorbed, the better the system. or more (the charcoal filter weighs 40 lbs by itself). What I can do, is offer some explanation as to what to look for when considering such a purchase. Oh, if only we had a crystal ball. Finally, take the time, energy and money necessary to maintain your system properly. Most manufacturers use 40 lbs. Filtration units that weigh 100 lbs. The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. All Rights Reserved. No returns accepted on this item. Applied Adhesive These coarse to extremely fine paper filters can trap particles as small as 0.001mm (many times smaller than a human hair).

Click here for more health and safety information. Obviously, the more odor absorbed, the better the system. or more (the charcoal filter weighs 40 lbs by itself). What I can do, is offer some explanation as to what to look for when considering such a purchase. Oh, if only we had a crystal ball. Finally, take the time, energy and money necessary to maintain your system properly. Most manufacturers use 40 lbs. Filtration units that weigh 100 lbs. The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. All Rights Reserved. No returns accepted on this item. Applied Adhesive These coarse to extremely fine paper filters can trap particles as small as 0.001mm (many times smaller than a human hair).  Next is the paper (sometimes foam, glass fiber or a similar material) filter stage. These are more expensive than blowers but bring with them several advantages beyond the obvious. The companies reflected in this article have been around a long time and have a long-standing reputation. Johnson Plastics Plus is located in the United States of America. My best advice is first, take your time and talk to company representatives but also their customers.

Next is the paper (sometimes foam, glass fiber or a similar material) filter stage. These are more expensive than blowers but bring with them several advantages beyond the obvious. The companies reflected in this article have been around a long time and have a long-standing reputation. Johnson Plastics Plus is located in the United States of America. My best advice is first, take your time and talk to company representatives but also their customers.  Most systems are designed to run on both but check to be sure.

Most systems are designed to run on both but check to be sure.  Some areas, however, struggle to maintain a consistent voltage power supply. Filtrabox (PAT Technology Systems) has come up with a unique solution with what they call an AIRDOCK. This is a filtration system that is totally modular. Of course, the larger the unit, the more noise it will create.

Some areas, however, struggle to maintain a consistent voltage power supply. Filtrabox (PAT Technology Systems) has come up with a unique solution with what they call an AIRDOCK. This is a filtration system that is totally modular. Of course, the larger the unit, the more noise it will create.  Yes, a digital motor is, in my opinion, better. Most of us, however, should be happy with 40 lbs. This means you will probably need a separate circuit that is dedicated to run your filtration system. It's NON toxic and NON porous as well. One company offers colored LEDs that show when each filter is approaching replacement time and when it needs replacing. Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation. Many environments dont permit outdoor venting for a variety of reasons, the least of which being the property owner doesnt want 4 holes drilled through their walls or roofs. Some of these are listed in the chart accompanying this article. Call us toll free 1-800-626-0664 for help with your product selection. The Model 300 laser fume extractor from Sentry Air Systems, Inc. is available in a portable version that includes heavy-duty casters and a portability handle for those who take their lasers off-site. filter. Laser marking and coding of packaging and products with traceable information such as barcodes, batch codes and sell by dates.

Yes, a digital motor is, in my opinion, better. Most of us, however, should be happy with 40 lbs. This means you will probably need a separate circuit that is dedicated to run your filtration system. It's NON toxic and NON porous as well. One company offers colored LEDs that show when each filter is approaching replacement time and when it needs replacing. Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation. Many environments dont permit outdoor venting for a variety of reasons, the least of which being the property owner doesnt want 4 holes drilled through their walls or roofs. Some of these are listed in the chart accompanying this article. Call us toll free 1-800-626-0664 for help with your product selection. The Model 300 laser fume extractor from Sentry Air Systems, Inc. is available in a portable version that includes heavy-duty casters and a portability handle for those who take their lasers off-site. filter. Laser marking and coding of packaging and products with traceable information such as barcodes, batch codes and sell by dates.  SIMPLY CALL US NOW TO SEE THESE LASER MACHINES IN ACTION AT OUR NEW NORTHAMPTON PREMISES. The activated charcoal actually absorbs the odors. Many of the materials we cut or engrave stink. Reducing the airflow reduces air noise and extends the life of the filter media. I did a full review of the VLS (Versa Laser System) and its HPDFO (High Power Density Focusing Optics) lens when it first came out in the May 2006 issue of EJ. In the end, we stuck close to our German roots, and have worked exclusively with TEKA for our filtration needs since 2005. If you are interested in a more detailed description of the gases and particles and how they can affect our bodies, check out What You Should Know About Laser Filtration Systems in the Sept. 2010 issue of EJ. TEKAs high-quality filtration systems paired with their reliability in performance soon proved to be a perfect match for our state-of-the-art laser cleaning systems. This is not something to guess at and, as the filters age, the amount of air that can pass through them declines.

SIMPLY CALL US NOW TO SEE THESE LASER MACHINES IN ACTION AT OUR NEW NORTHAMPTON PREMISES. The activated charcoal actually absorbs the odors. Many of the materials we cut or engrave stink. Reducing the airflow reduces air noise and extends the life of the filter media. I did a full review of the VLS (Versa Laser System) and its HPDFO (High Power Density Focusing Optics) lens when it first came out in the May 2006 issue of EJ. In the end, we stuck close to our German roots, and have worked exclusively with TEKA for our filtration needs since 2005. If you are interested in a more detailed description of the gases and particles and how they can affect our bodies, check out What You Should Know About Laser Filtration Systems in the Sept. 2010 issue of EJ. TEKAs high-quality filtration systems paired with their reliability in performance soon proved to be a perfect match for our state-of-the-art laser cleaning systems. This is not something to guess at and, as the filters age, the amount of air that can pass through them declines.  This way, all of the guesswork is taken out of it, as the fume extraction unit will be rightsized for both the laser system and the application for which youll be using it. The store will not work correctly in the case when cookies are disabled. air purifiers, fume extractors, dust collectors, air filtration systems, dust, chemical odor removal Proudly Made In North America , 1-800-626-0664, Your Source of HEPA Air Purifiers, Air Filtration Systems With Deep Bed, High Capacity Filtration , Shipped To You Factory Fresh, BP2000 Industrial Commercial Grade Air Filtration, BreathEasy BH Home Office Small Commercial, Construction Renovation Dust Odor Filtration, MedEvac Podiatry Podiatrists Debris Capture HH, Printing Graphic Arts Dust Odor Filtration, Fume Extractor System Articulating Arms 1, Fume Extractor System Articulating Arms 2, MedEvac Podiatry Podiatrists Debris Capture.

This way, all of the guesswork is taken out of it, as the fume extraction unit will be rightsized for both the laser system and the application for which youll be using it. The store will not work correctly in the case when cookies are disabled. air purifiers, fume extractors, dust collectors, air filtration systems, dust, chemical odor removal Proudly Made In North America , 1-800-626-0664, Your Source of HEPA Air Purifiers, Air Filtration Systems With Deep Bed, High Capacity Filtration , Shipped To You Factory Fresh, BP2000 Industrial Commercial Grade Air Filtration, BreathEasy BH Home Office Small Commercial, Construction Renovation Dust Odor Filtration, MedEvac Podiatry Podiatrists Debris Capture HH, Printing Graphic Arts Dust Odor Filtration, Fume Extractor System Articulating Arms 1, Fume Extractor System Articulating Arms 2, MedEvac Podiatry Podiatrists Debris Capture.  The filter unit takes care of the rest. Over the past 15 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning solutions. of activated charcoal in each unit. BASE UNITS: Some units, such as the BOFA AD Base 1 Oracle, the ULS 2000 and the Purex Ebase units, are designed for a laser to sit on top of them.

The filter unit takes care of the rest. Over the past 15 years we have equipped numerous companies across varying industries with our state-of-the-art laser cleaning solutions. of activated charcoal in each unit. BASE UNITS: Some units, such as the BOFA AD Base 1 Oracle, the ULS 2000 and the Purex Ebase units, are designed for a laser to sit on top of them.  They require an investment in the beginning but if you buy a quality device, you might never have to buy another. Basically, this means there is a void at the bottom of the cabinet where the heaviest particles can just drop out of the air stream and land in a tray in the bottom of the cabinet. We recommend checking the filters on a bi-weekly basisto monitor debris build-up. {{product.adhesive===''?

They require an investment in the beginning but if you buy a quality device, you might never have to buy another. Basically, this means there is a void at the bottom of the cabinet where the heaviest particles can just drop out of the air stream and land in a tray in the bottom of the cabinet. We recommend checking the filters on a bi-weekly basisto monitor debris build-up. {{product.adhesive===''?  By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. JavaScript seems to be disabled in your browser. Prices and offers are subject to change. free shipping!*. Adapt Laser specializes in providing the highest-quality laser cleaning systems available. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable.

By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. JavaScript seems to be disabled in your browser. Prices and offers are subject to change. free shipping!*. Adapt Laser specializes in providing the highest-quality laser cleaning systems available. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable.  a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. #ournhs #nhs #ctrlasers #socialdistancing #standtogetherunited #british #forthegreatergood https://t.co/HpQCELaROQ, CTR | RF CO2 Laser Engraving Wooden Business Cards https://t.co/Di2JsT8ReZ via @YouTube, CTR | RF CO2 Laser Engraving Dinosaur Fossil Granite Coaster https://t.co/4vgrFVXRi7 via @YouTube, Units 5-6, Sterling Business Park This can easily damage equipment by running the power supply and motor at a voltage that is too high or too low. Forms, TECH Restock coming April 2022 - To pre-order, please contact sales@inskmith.ca. CFM REQUIREMENT: Each unit is rated in one of two ways (or both).

a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. #ournhs #nhs #ctrlasers #socialdistancing #standtogetherunited #british #forthegreatergood https://t.co/HpQCELaROQ, CTR | RF CO2 Laser Engraving Wooden Business Cards https://t.co/Di2JsT8ReZ via @YouTube, CTR | RF CO2 Laser Engraving Dinosaur Fossil Granite Coaster https://t.co/4vgrFVXRi7 via @YouTube, Units 5-6, Sterling Business Park This can easily damage equipment by running the power supply and motor at a voltage that is too high or too low. Forms, TECH Restock coming April 2022 - To pre-order, please contact sales@inskmith.ca. CFM REQUIREMENT: Each unit is rated in one of two ways (or both).