Do not smoke during use.

WARNING marking concerning Risk of Hearing Loss. Performing routine air supply maintenance will allow the Soda Blaster to operate more safely and will also reduce wear on the Soda Blaster. I would say read the entire user's manual, except that it is missing, so my best advice now is to read this entire memo before using the sand blaster.

improper adjustment can result in Soda Blaster failure or other serious hazards. Exposure to aluminum oxide (a dust generated from material removing processes) can result in eye, skin and breathing irritation. Install an in-line shutoff valve to allow immediate control over the air supply in an emergency, even if a hose is ruptured. Copyright 2020 by Harbor Freight Tools. The grit and dirt does get into everything, but it does not stick firmly to anything (except grease or oily items). Efficient pressurized blaster moves abrasives at 80 to 90 percent of air speed for real blasting power. Excess moisture will cause the abrasive to slow or stop flowing through the Abrasive Outlet Pipe.

More notes on media type below. Connect the air hose to the air valveof the Soda Blaster. Closer distance gives a smaller blast spot and more aggressive blasting for stubborn rust removal.

3/8 x 13 air belt sander with accessories (13 pages), 2-3/4" x 17-1/2" air inline sander (15 pages), 6" composite palm grop random orbital santer (16 pages), Air wet hbbd```b`` D(HT x4DDT@d "YK&HI@|=[`3Fg` x&

endstream

endobj

startxref

0

%%EOF

104 0 obj

<>stream

ftypjp2 jp2 jpxbjpx rreq @ - Ojp2h ihdr J colr pclr wwwvvvuuurrrssstttiiiccceeebbbaaa```___^^^]]]WWWQQQRRRNNNMMMLLLKKKIIIlllVVVSSSEEECCC999222+++&&&'''$$$""" !!!###%%%444xxxXXXGGG;;;***((()))---000///111555,,,HHH333PPP?? HWmo+/T(PWJrmQ8Hld3Iz Step2: Attach the PRESSURE GAUGE to the top of the INTAKE MANIFOLD. j"V09ZG&:>V x73K1b$&h88YpCi OfM+~'g%af%0CA &[q-gzrd

2@.l*8U\ZIRB)Cj%YDq(?RI%:e\jJ;s4/7R>MM3\BqRT+8OiI&%C3 ^oJ:OaBw!+j={O%IvOmM44eCi4g{P8/s@

n' VO~%q The shop vac will clean a smooth floor in a single pass. I didn't like the heavy handed operation of the control lever, so this may be better if it was changed to a ball valve.

75 0 obj

<>

endobj

89 0 obj

<>/Filter/FlateDecode/ID[<890E8194AA2EC47906724CE6B29E4680><9AA21B7D7F7F4DABBAECB6D2E591F1EB>]/Index[75 30]/Info 74 0 R/Length 87/Prev 324004/Root 76 0 R/Size 105/Type/XRef/W[1 3 1]>>stream

If any parts are missing or broken, please call 1-888-866-5797 as soon as possible. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you.THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. For gross removal of paint and rust you may want maximum pressure on the blaster (do not exceed 125 psi safe pressure limit). All rights reserved. Tighten using a wrench on the back of the Gauge block. --------------

This warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

If the compressor is supplying humid air the filter bowl will accumulate water and needs to be drained occasionally. If the safety valve does not release excess air pressure, stop all work and use the air compressor to release pressure in the tank.

Then again, this control valve didn't always shut off by itself anyway. Step3: Attach both HANDLE BARS to the TANK (#1) using the four SCREWS, NUTS, and WASHERS. There is a sealed filling and inspection cap on top of the pressurized media tank. As such it will work with 50%-60% duty cycle with my compressor, giving one minute of trigger time

Keep the input valve and air control valve wide open at all times when blasting. Wear hearing protection.

Air consumption for the blaster will be nearly proportional to the pressure being used. ]ze. Indicates a hazardous situation which, if not avoided,could result in minor or moderate injury. At 60 psi it will work to remove paint and mild rust, but it works much better (more aggressively) with 75-psi or higher pressure. DO NOT OVERREACH. Attach an air hose to the compressors air outlet. Use Media Regulator Knob to adjust the media flow rate. The sudden backflow of air can also purge some water out of the input filter and water separator (but will not empty the water bowl completely). The fuzzy round brush attachment for the shop vac did a nice job of cleaning out the car interior and all over the car body and everything I could reach in the boot and engine bay (and anything else I could reach on the work bench and shelves. Pregnant women or people who have impaired blood circulation to the hand, past hand injuries, nervous system disorders, diabetes, or Raynauds Disease should not use this tool. Removing heavy rust from steel parts is a cinch, as it can ultimately remove steel from steel parts. Due to continuing improvements, actual product may differ slightly from the product described herein. Daily Air Supply Maintenance:Every day, maintain the air supply according to the component manufacturers instructions. The warnings and precautions discussed in this manual cannot cover all possible conditions and situations that may occur. The fine grade is good for light paint and rust removal. The fill neck has a fat O-ring seal on a depressed shoulder at the base of the thread.

Wear ANSI-approved eye protection. *qrV

myU6L3hK>(cBeLgthF2Wjj}4UFH

/ *

endstream

endobj

80 0 obj

<>stream

The work area must not allow access by children or pets to prevent distraction and injury. Poor or irregular flow of the abrasive may also be due to low air pressure or a worn Nozzle. Designate a work area that is clean and well-lit. Coarser material tends to clog up the nozzle on smaller blaster units (including this one). 40 LB. Specify UPC number when ordering:40 lb. It works well for general use, but for lots of heavy rust removal I might prefer something more coarse. Use respiratory protection when source controls cannot keep silica exposures below the NIOSH REL. This unit is on the larger end of the scale for a home shop blaster. Figuring about 2/3 pound of abrasive use for each minute of trigger time, a full tank could keep you working for 165 minutes of continuous use. jP

1. Equipped with a nozzle end shut-off valve, pressure gauge, ceramic nozzle, 9 foot hose, filling funnel, water trap, 6" rubber wheels, and canvas hood. Turn on the compressor and set the regulator to the pressure recommended for this Soda Blaster (90 PSI). I bought 70 grit "aggressive abrasive" for "remove paint and rust".

The SAND HOSE needs replacing when its side walls develop leaks or show blisters in the surface. X"&%2dtvE= 'Fd1UOS*{I_IGA0'HfH:(Jv|f E-q|ujt ~ ? SAVE THIS MANUAL You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures, maintenance procedures, trouble shooting, parts list, and diagram. For big jobs at minimal expense you might use sifted play sand (assuming you can keep it dry). Pull back on the blue Air Hose Connector collar and insert the Air Hose deep into the fitting. If you find the blaster to work well at 80-90 psi, you may want to reduce the input supply pressure not to exceed 90 psi, as higher pressure will consume more air than necessary and reduce productivity (available trigger time). hR})7xH\''Pr

NlO6m~%lH9W(Pe=:~}i9u3{xJ{t \jWr!'']4Hw@9xabJt(S{znA/?;Uy)6Md_mtgjk^m#h WS7u};O.|w.o_ *

endstream

endobj

79 0 obj

<>stream

There must not be hazardous objects (such as utility lines or foreign objects) nearby that will present a hazard while working. Harbor freight tools central pneumatic series 40 lb pressurized sandblaster model 34202 assembly and operating instructions, 3491 Mission Oaks Blvd. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OFREPLACEMENT PARTS THERETO.

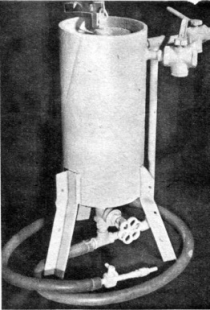

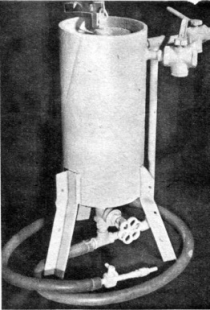

If our inspection verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. This is a pressure feed sand blasting unit I borrowed from our club tool lending program.

Follow instructions for lubricating and changing accessories. Intake Manifold Refer to Figure 1. NIOSH recommends the following measures to reduce crystalline silica exposures in the workplace and prevent silicosis and silicosis-related deaths: This tool vibrates during use. That pressure is non functional with this unit, but it indicates a rough air consumption figure of 9.0-scfm @ 45-psi. If you disconnect the supply hose, then open the shut-off valve, tank pressure will force backflow of air at the input coupling. Use containment methods such as blast-cleaning machines and cabinets to control the hazard and protect adjacent workers from exposure. b rbGGCGFG 6F 03]G89e| 0cu Cy @ MX> 0KW

endstream

endobj

76 0 obj

<>

endobj

77 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

78 0 obj

<>stream

A loose accessory may detach or break during operation. @ Y

endstream

endobj

40 0 obj

<>

endobj

41 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

42 0 obj

<>

endobj

43 0 obj

<>

endobj

44 0 obj

<>

endobj

45 0 obj

<>

endobj

46 0 obj

[/Indexed 61 0 R 255 63 0 R]

endobj

47 0 obj

[/ICCBased 59 0 R]

endobj

48 0 obj

<>

endobj

49 0 obj

<>stream

Use tools with the lowest vibration when there is a choice. The blast spot on the work surface will be 1/8 to 1/4 inch diameter depending on distance of the blast nozzle from the surface. 10.

Home HARBOR FREIGHT HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster. When removing paint or light rust from sheet metal you may need to reduce air pressure and use finer grain blast media to prevent excess damage to the work piece. If the Soda Blaster will not be used at this time, turn off and detach the air supply, safely discharge any residual air pressure, and close the valves to prevent accidental operation.

At the output working end of the hose is the nozzle control valve in the blaster head (which is not a ball valve here but could be for other blaster models). Diagrams within this manual may not be drawn proportionally. Your email address will not be published. Wear NIOSH-approved dust mask/respirator. If you have a big job to do and want continuous trigger time, you would need at least a 5-hp compressor to give about 19-scfm @ 90-psi. Difference is, a ball valve does not shut off automatically if you drop it. Do not use sand or other blasting materials that contain crystalline silica.Note: Use only dry and clean abrasives to avoid clogging the Soda Blaster.Note: The Nozzle size depends on grit of media used. Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from the date of purchase. We will return repaired products at our expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of our warranty, then you must bear the cost of returning the product.

Do not reach over or across running machines. TO PREVENT SERIOUS INJURY FROM EXPLOSION:Use only clean, dry, regulated, compressed air to power this Soda Blaster.

This is how you relieve tank pressure before opening the tank cap to check or refill media material. 11. Hints for use:

It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator. It would have been better if the bonnet and boot lid were in place to keep most of the grit out of the boot and engine bay, but that didn't bother me much with the body coming off anyway. This is the safety alert symbol. DO NOT ABUSE THE POWER CORD. WARNING marking concerning Risk of Explosion. The grit is similar to granulated sugar. When the lever is pressed the pin is retracted so the hose can open up to full bore for clear passage of air and media grit to the blast nozzle. It will work with a smaller compressor, but with a shortened duty cycle. Always close the media control valve on the bottom of the tank before closing the air control valve. The nozzle control valve at the blast head also leaks, sometimes a little once it is shut off, or possibly a lot when it refuses to shut off. Central Pneumatic Series 40 Lb Pressurized Sandblaster Model 34202 Assembly and Operating Instructions. SPECIFICATIONS Capacity: Working Pressure Delivery Rate Overall Dimensions Weight: 40 lbs. You might also use a fan to blow away the finer dust while sifting. Step2: Slide the HANDLE GRIPS onto the HANDLE BARS.

Turn PRESSURE GAUGE so that its face is over the lower side hold of the INTAKE MANIFOLD. The grit goes everywhere, so don't have an open engine or gearbox in the room when doing this.

If you disconnect the air supply and relieve the tank pressure, then re-pressurizing the tank will require some air flow from the compressor before continuing operation. Inspect compressors cord periodically and, if damaged, have them repaired by an authorized technician. When unpacking, make sure that the product is intact and undamaged. Allow time for the trapped aggregate to safely discharge back into the Tank. abrasive capacity for big jobs. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAI THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. Step3: Attach the JOINT PIPE (#13) to the upper side port of the TANK (#1).

Do not allow pressure to exceed 125 PSI. Empty the Tank, and clean external surfaces of the Soda Blaster with clean, dry cloth. It may be appropriate to order a replacement hose for the inside of this control head, along with a few spare ceramic nozzles. If the Soda Blaster requires more force to accomplish the task, verify that the Soda Blaster receives sufficient, unobstructed airflow (CFM) and increase the pressure (PSI) output of the regulator up to the maximum air pressure rating of this Soda Blaster. Between the bottom of the tank and the venturi is a medial control valve. Parts may not be interchangeable. For technical questions and replacement parts, please call 1-800-444-3353. Cautions and Warnings first:

Once the nozzle is removed you can use the air pressure (working the air control valve) to blow out the hose and blast head. HWr6CD0q/GVZwZ;Zku$JY n;i@bqX. There will be no attempt here to turn an amateur blast operator into a skilled professional by words alone. AIR/SAND SUPPLY REQUIREMENTS Hose ID 3/8" 3/8" 1/2" 1/2" Hose Length 50 ft. 25 ft. 50 ft. 25 ft. Nozzle ID 0.1" 0.125" 0.15" 0.175" Compressor HP 2 4 7 10 CFM @ 125 PSI 6 12 20 25 Sand Use Per Hour 60 lbs. Vertical surfaces and anything higher up is subject to a fine coat of static cling dust that is fairly easy to wipe off or vacuum up. Insert the Pickup Tube into the Tank and tighten the Bushing.

?ooo@@@666hhh~~~888===:::<<. Do not carry tools by the cord. TO PREVENT SERIOUSINJURY FROM ACCIDENTAL OPERATION:close all Valves, detach the air supply, safely discharge any residual air pressure in the Soda Blaster, and close all Valves again before performing any procedure in this section. Step 3: Attach one of the WHEELS to the AXLE using one of the COTTER PINS. MAINTAIN TOOLS WITH CARE. 9. Speed of the media particles can be 80% to 90% of the velocity of the air blasting through the nozzle, so it can be very aggressive when held close up with high pressure.

Step 5: Remove the TANK CAP (#12). Write the invoice number on the inside of the front cover. / Camarillo, CA 93011 Copyright 1997 by Harbor Freight Tools. Insert the knob on the top of the Air Regulator (9) through the Bracket (3). For technical questions and replacement parts, please call 1-800-444-3353. Keep tools sharp and clean for better and safer performance. on HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 62355 Central Pneumatic 1 Inch Pistol Grip Air Impact Wrench Owners Manual, Harbor Freight BADLAND WINCHES 120V AC Electric Winch Owners Manual, HARBOR FREIGHT 60801 Portable Soda Blaster Owner's Manual, HARBOR FREIGHT 42858 3 Inch Twisted Wire Brush Instructions, HARBOR FREIGHT DIY GIANT BLOCK GAME User Manual, HARBOR FREIGHT 57808 2 Amp Variable Speed Oscillating Multi Tool Owner's Manual, TRIPP LITE PDUMH Series Metered Rack PDU with Automatic Transfer Switch Owners Manual, AJAX 8706 KeyPad Wireless Touch Keyboard User Manual, Meizhou Hongfeng Arts Crafts 266285 BJ 57IN Snowman With Snowflakes Instruction Manual, AJAX 7661 StreetSiren Wireless Outdoor Siren User Manual, AJAX 17938 12V PSU for Hub/Hub Plus/ReX Power Supply Unit User Manual, ZERFUN G8 Pro Wireless Microphone System User Manual, Airrex Infrared Heater AH-200/300/800 User Manual, 2017 Toyota Camry Hybrid LE Fuse Box Diagrams, 2017 Mitsubishi Lancer 4WD Fuse Box Diagrams, Mitsubishi Lancer Passenger and Engine Fuse Box Diagram, Mira Honesty ERD Bar Valve and Fittings User Manual, Cubic Feet per Minute flow at standard conditions. Personal equipment calls for (minimally) long sleeves, gloves, closed goggles, full face shield and a filter mask.

497A""

A"TD

.j?,\~gO.v ?@&)34q~: e y@2$J B H- 3"Kd P3. Repeated or long-term exposure to vibration may cause temporary or permanent physical injury, particularly to the hands, arms and shoulders. After doing some blasting in my 16x21 foot shop space, the place at first appeared to be a horrible mess with about 20 pounds of grit and dust on the floor and all over everything, including inside the car. Repair any leaks found. The pipe then splits with one pipe going to pressurize the media tank. Addresses practices not related to personal injury.

Step 3: Open the NOZZLE SHUT OFF VALVE (#18C) by turning it to the vertical position. There are three ball valves on this unit, not counting the control valve at the blasting head. Notice the pressure rating and air flow requirements. You MUST relieve tank pressure completely before removing the tank cap. MAINTENANCE 1. Wear washable or disposable protective clothes at the work site. Include vibration-free periods each day of work. OPERATIONS Loading Abrasives Warning! If the nozzle control valve does not shut off completely, then close the air control valve before removing the nozzle. Personal Equipment, Dirt and Cleanup:

Even then you would have your hair and ears full of gritty dust. Top Assembly Refer to Figure 6. Proper ventilation in the work area is required. Handle Bars Refer to Figure 7. Step 4: Slide the AXLE through the hole in the bottom of the two HANDLE BARS (#6). If that gets the hose clear you can turn the blast head around and use the air pressure to back flush the blast head (with the head valve open), then reassemble the head to hose and reinstall the nozzle. If the blast nozzle becomes clogged during use, immediately close the media control valve at bottom of the tank. Close the in-line shutoff valve between the compressor and the Soda Blaster. Proceed at your own risk. Obey the manual for the air compressor used to power this Soda Blaster.

Report all cases of silicosis to State health departments and to OSHA or the Mine Safety and Health Administration (MSHA). Instructions with the sand blaster call for using a hood, which is a canvas full head cover with a clear shield in front. MAINTAIN CORRECT AIR PRESSURE WHENEVER WORKING.

Sitemap 19

WARNING marking concerning Risk of Hearing Loss. Performing routine air supply maintenance will allow the Soda Blaster to operate more safely and will also reduce wear on the Soda Blaster. I would say read the entire user's manual, except that it is missing, so my best advice now is to read this entire memo before using the sand blaster.

WARNING marking concerning Risk of Hearing Loss. Performing routine air supply maintenance will allow the Soda Blaster to operate more safely and will also reduce wear on the Soda Blaster. I would say read the entire user's manual, except that it is missing, so my best advice now is to read this entire memo before using the sand blaster.  improper adjustment can result in Soda Blaster failure or other serious hazards. Exposure to aluminum oxide (a dust generated from material removing processes) can result in eye, skin and breathing irritation. Install an in-line shutoff valve to allow immediate control over the air supply in an emergency, even if a hose is ruptured. Copyright 2020 by Harbor Freight Tools. The grit and dirt does get into everything, but it does not stick firmly to anything (except grease or oily items). Efficient pressurized blaster moves abrasives at 80 to 90 percent of air speed for real blasting power. Excess moisture will cause the abrasive to slow or stop flowing through the Abrasive Outlet Pipe.

improper adjustment can result in Soda Blaster failure or other serious hazards. Exposure to aluminum oxide (a dust generated from material removing processes) can result in eye, skin and breathing irritation. Install an in-line shutoff valve to allow immediate control over the air supply in an emergency, even if a hose is ruptured. Copyright 2020 by Harbor Freight Tools. The grit and dirt does get into everything, but it does not stick firmly to anything (except grease or oily items). Efficient pressurized blaster moves abrasives at 80 to 90 percent of air speed for real blasting power. Excess moisture will cause the abrasive to slow or stop flowing through the Abrasive Outlet Pipe.  More notes on media type below. Connect the air hose to the air valveof the Soda Blaster. Closer distance gives a smaller blast spot and more aggressive blasting for stubborn rust removal.

More notes on media type below. Connect the air hose to the air valveof the Soda Blaster. Closer distance gives a smaller blast spot and more aggressive blasting for stubborn rust removal.  3/8 x 13 air belt sander with accessories (13 pages), 2-3/4" x 17-1/2" air inline sander (15 pages), 6" composite palm grop random orbital santer (16 pages), Air wet hbbd```b`` D(HT x4DDT@d "YK&HI@|=[`3Fg` x&

endstream

endobj

startxref

0

%%EOF

104 0 obj

<>stream

3/8 x 13 air belt sander with accessories (13 pages), 2-3/4" x 17-1/2" air inline sander (15 pages), 6" composite palm grop random orbital santer (16 pages), Air wet hbbd```b`` D(HT x4DDT@d "YK&HI@|=[`3Fg` x&

endstream

endobj

startxref

0

%%EOF

104 0 obj

<>stream

ftypjp2 jp2 jpxbjpx rreq @ - Ojp2h ihdr J colr pclr wwwvvvuuurrrssstttiiiccceeebbbaaa```___^^^]]]WWWQQQRRRNNNMMMLLLKKKIIIlllVVVSSSEEECCC999222+++&&&'''$$$""" !!!###%%%444xxxXXXGGG;;;***((()))---000///111555,,,HHH333PPP?? HWmo+/T(PWJrmQ8Hld3Iz Step2: Attach the PRESSURE GAUGE to the top of the INTAKE MANIFOLD. j"V09ZG&:>V x73K1b$&h88YpCi OfM+~'g%af%0CA &[q-gzrd

2@.l*8U\ZIRB)Cj%YDq(?RI%:e\jJ;s4/7R>MM3\BqRT+8OiI&%C3 ^oJ:OaBw!+j={O%IvOmM44eCi4g{P8/s@

n' VO~%q The shop vac will clean a smooth floor in a single pass. I didn't like the heavy handed operation of the control lever, so this may be better if it was changed to a ball valve.

ftypjp2 jp2 jpxbjpx rreq @ - Ojp2h ihdr J colr pclr wwwvvvuuurrrssstttiiiccceeebbbaaa```___^^^]]]WWWQQQRRRNNNMMMLLLKKKIIIlllVVVSSSEEECCC999222+++&&&'''$$$""" !!!###%%%444xxxXXXGGG;;;***((()))---000///111555,,,HHH333PPP?? HWmo+/T(PWJrmQ8Hld3Iz Step2: Attach the PRESSURE GAUGE to the top of the INTAKE MANIFOLD. j"V09ZG&:>V x73K1b$&h88YpCi OfM+~'g%af%0CA &[q-gzrd

2@.l*8U\ZIRB)Cj%YDq(?RI%:e\jJ;s4/7R>MM3\BqRT+8OiI&%C3 ^oJ:OaBw!+j={O%IvOmM44eCi4g{P8/s@

n' VO~%q The shop vac will clean a smooth floor in a single pass. I didn't like the heavy handed operation of the control lever, so this may be better if it was changed to a ball valve.  75 0 obj

<>

endobj

89 0 obj

<>/Filter/FlateDecode/ID[<890E8194AA2EC47906724CE6B29E4680><9AA21B7D7F7F4DABBAECB6D2E591F1EB>]/Index[75 30]/Info 74 0 R/Length 87/Prev 324004/Root 76 0 R/Size 105/Type/XRef/W[1 3 1]>>stream

If any parts are missing or broken, please call 1-888-866-5797 as soon as possible. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you.THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. For gross removal of paint and rust you may want maximum pressure on the blaster (do not exceed 125 psi safe pressure limit). All rights reserved. Tighten using a wrench on the back of the Gauge block. --------------

This warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

If the compressor is supplying humid air the filter bowl will accumulate water and needs to be drained occasionally. If the safety valve does not release excess air pressure, stop all work and use the air compressor to release pressure in the tank.

75 0 obj

<>

endobj

89 0 obj

<>/Filter/FlateDecode/ID[<890E8194AA2EC47906724CE6B29E4680><9AA21B7D7F7F4DABBAECB6D2E591F1EB>]/Index[75 30]/Info 74 0 R/Length 87/Prev 324004/Root 76 0 R/Size 105/Type/XRef/W[1 3 1]>>stream

If any parts are missing or broken, please call 1-888-866-5797 as soon as possible. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you.THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. For gross removal of paint and rust you may want maximum pressure on the blaster (do not exceed 125 psi safe pressure limit). All rights reserved. Tighten using a wrench on the back of the Gauge block. --------------

This warranty does not apply to damage due directly or indirectly, to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities, criminal activity, improper installation, normal wear and tear, or to lack of maintenance.

If the compressor is supplying humid air the filter bowl will accumulate water and needs to be drained occasionally. If the safety valve does not release excess air pressure, stop all work and use the air compressor to release pressure in the tank.  Then again, this control valve didn't always shut off by itself anyway. Step3: Attach both HANDLE BARS to the TANK (#1) using the four SCREWS, NUTS, and WASHERS. There is a sealed filling and inspection cap on top of the pressurized media tank. As such it will work with 50%-60% duty cycle with my compressor, giving one minute of trigger time

Keep the input valve and air control valve wide open at all times when blasting. Wear hearing protection.

Air consumption for the blaster will be nearly proportional to the pressure being used. ]ze. Indicates a hazardous situation which, if not avoided,could result in minor or moderate injury. At 60 psi it will work to remove paint and mild rust, but it works much better (more aggressively) with 75-psi or higher pressure. DO NOT OVERREACH. Attach an air hose to the compressors air outlet. Use Media Regulator Knob to adjust the media flow rate. The sudden backflow of air can also purge some water out of the input filter and water separator (but will not empty the water bowl completely). The fuzzy round brush attachment for the shop vac did a nice job of cleaning out the car interior and all over the car body and everything I could reach in the boot and engine bay (and anything else I could reach on the work bench and shelves. Pregnant women or people who have impaired blood circulation to the hand, past hand injuries, nervous system disorders, diabetes, or Raynauds Disease should not use this tool. Removing heavy rust from steel parts is a cinch, as it can ultimately remove steel from steel parts. Due to continuing improvements, actual product may differ slightly from the product described herein. Daily Air Supply Maintenance:Every day, maintain the air supply according to the component manufacturers instructions. The warnings and precautions discussed in this manual cannot cover all possible conditions and situations that may occur. The fine grade is good for light paint and rust removal. The fill neck has a fat O-ring seal on a depressed shoulder at the base of the thread.

Wear ANSI-approved eye protection. *qrV

myU6L3hK>(cBeLgthF2Wjj}4UFH

/ *

endstream

endobj

80 0 obj

<>stream

The work area must not allow access by children or pets to prevent distraction and injury. Poor or irregular flow of the abrasive may also be due to low air pressure or a worn Nozzle. Designate a work area that is clean and well-lit. Coarser material tends to clog up the nozzle on smaller blaster units (including this one). 40 LB. Specify UPC number when ordering:40 lb. It works well for general use, but for lots of heavy rust removal I might prefer something more coarse. Use respiratory protection when source controls cannot keep silica exposures below the NIOSH REL. This unit is on the larger end of the scale for a home shop blaster. Figuring about 2/3 pound of abrasive use for each minute of trigger time, a full tank could keep you working for 165 minutes of continuous use. jP

1. Equipped with a nozzle end shut-off valve, pressure gauge, ceramic nozzle, 9 foot hose, filling funnel, water trap, 6" rubber wheels, and canvas hood. Turn on the compressor and set the regulator to the pressure recommended for this Soda Blaster (90 PSI). I bought 70 grit "aggressive abrasive" for "remove paint and rust".

Then again, this control valve didn't always shut off by itself anyway. Step3: Attach both HANDLE BARS to the TANK (#1) using the four SCREWS, NUTS, and WASHERS. There is a sealed filling and inspection cap on top of the pressurized media tank. As such it will work with 50%-60% duty cycle with my compressor, giving one minute of trigger time

Keep the input valve and air control valve wide open at all times when blasting. Wear hearing protection.

Air consumption for the blaster will be nearly proportional to the pressure being used. ]ze. Indicates a hazardous situation which, if not avoided,could result in minor or moderate injury. At 60 psi it will work to remove paint and mild rust, but it works much better (more aggressively) with 75-psi or higher pressure. DO NOT OVERREACH. Attach an air hose to the compressors air outlet. Use Media Regulator Knob to adjust the media flow rate. The sudden backflow of air can also purge some water out of the input filter and water separator (but will not empty the water bowl completely). The fuzzy round brush attachment for the shop vac did a nice job of cleaning out the car interior and all over the car body and everything I could reach in the boot and engine bay (and anything else I could reach on the work bench and shelves. Pregnant women or people who have impaired blood circulation to the hand, past hand injuries, nervous system disorders, diabetes, or Raynauds Disease should not use this tool. Removing heavy rust from steel parts is a cinch, as it can ultimately remove steel from steel parts. Due to continuing improvements, actual product may differ slightly from the product described herein. Daily Air Supply Maintenance:Every day, maintain the air supply according to the component manufacturers instructions. The warnings and precautions discussed in this manual cannot cover all possible conditions and situations that may occur. The fine grade is good for light paint and rust removal. The fill neck has a fat O-ring seal on a depressed shoulder at the base of the thread.

Wear ANSI-approved eye protection. *qrV

myU6L3hK>(cBeLgthF2Wjj}4UFH

/ *

endstream

endobj

80 0 obj

<>stream

The work area must not allow access by children or pets to prevent distraction and injury. Poor or irregular flow of the abrasive may also be due to low air pressure or a worn Nozzle. Designate a work area that is clean and well-lit. Coarser material tends to clog up the nozzle on smaller blaster units (including this one). 40 LB. Specify UPC number when ordering:40 lb. It works well for general use, but for lots of heavy rust removal I might prefer something more coarse. Use respiratory protection when source controls cannot keep silica exposures below the NIOSH REL. This unit is on the larger end of the scale for a home shop blaster. Figuring about 2/3 pound of abrasive use for each minute of trigger time, a full tank could keep you working for 165 minutes of continuous use. jP

1. Equipped with a nozzle end shut-off valve, pressure gauge, ceramic nozzle, 9 foot hose, filling funnel, water trap, 6" rubber wheels, and canvas hood. Turn on the compressor and set the regulator to the pressure recommended for this Soda Blaster (90 PSI). I bought 70 grit "aggressive abrasive" for "remove paint and rust".  The SAND HOSE needs replacing when its side walls develop leaks or show blisters in the surface. X"&%2dtvE= 'Fd1UOS*{I_IGA0'HfH:(Jv|f E-q|ujt ~ ? SAVE THIS MANUAL You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures, maintenance procedures, trouble shooting, parts list, and diagram. For big jobs at minimal expense you might use sifted play sand (assuming you can keep it dry). Pull back on the blue Air Hose Connector collar and insert the Air Hose deep into the fitting. If you find the blaster to work well at 80-90 psi, you may want to reduce the input supply pressure not to exceed 90 psi, as higher pressure will consume more air than necessary and reduce productivity (available trigger time). hR})7xH\''Pr

NlO6m~%lH9W(Pe=:~}i9u3{xJ{t \jWr!'']4Hw@9xabJt(S{znA/?;Uy)6Md_mtgjk^m#h WS7u};O.|w.o_ *

endstream

endobj

79 0 obj

<>stream

There must not be hazardous objects (such as utility lines or foreign objects) nearby that will present a hazard while working. Harbor freight tools central pneumatic series 40 lb pressurized sandblaster model 34202 assembly and operating instructions, 3491 Mission Oaks Blvd. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OFREPLACEMENT PARTS THERETO.

The SAND HOSE needs replacing when its side walls develop leaks or show blisters in the surface. X"&%2dtvE= 'Fd1UOS*{I_IGA0'HfH:(Jv|f E-q|ujt ~ ? SAVE THIS MANUAL You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures, maintenance procedures, trouble shooting, parts list, and diagram. For big jobs at minimal expense you might use sifted play sand (assuming you can keep it dry). Pull back on the blue Air Hose Connector collar and insert the Air Hose deep into the fitting. If you find the blaster to work well at 80-90 psi, you may want to reduce the input supply pressure not to exceed 90 psi, as higher pressure will consume more air than necessary and reduce productivity (available trigger time). hR})7xH\''Pr

NlO6m~%lH9W(Pe=:~}i9u3{xJ{t \jWr!'']4Hw@9xabJt(S{znA/?;Uy)6Md_mtgjk^m#h WS7u};O.|w.o_ *

endstream

endobj

79 0 obj

<>stream

There must not be hazardous objects (such as utility lines or foreign objects) nearby that will present a hazard while working. Harbor freight tools central pneumatic series 40 lb pressurized sandblaster model 34202 assembly and operating instructions, 3491 Mission Oaks Blvd. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OFREPLACEMENT PARTS THERETO.  If our inspection verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. This is a pressure feed sand blasting unit I borrowed from our club tool lending program.

If our inspection verifies the defect, we will either repair or replace the product at our election or we may elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. This is a pressure feed sand blasting unit I borrowed from our club tool lending program.  Follow instructions for lubricating and changing accessories. Intake Manifold Refer to Figure 1. NIOSH recommends the following measures to reduce crystalline silica exposures in the workplace and prevent silicosis and silicosis-related deaths: This tool vibrates during use. That pressure is non functional with this unit, but it indicates a rough air consumption figure of 9.0-scfm @ 45-psi. If you disconnect the supply hose, then open the shut-off valve, tank pressure will force backflow of air at the input coupling. Use containment methods such as blast-cleaning machines and cabinets to control the hazard and protect adjacent workers from exposure. b rbGGCGFG 6F 03]G89e| 0cu Cy @ MX> 0KW

endstream

endobj

76 0 obj

<>

endobj

77 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

78 0 obj

<>stream

A loose accessory may detach or break during operation. @ Y

endstream

endobj

40 0 obj

<>

endobj

41 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

42 0 obj

<>

endobj

43 0 obj

<>

endobj

44 0 obj

<>

endobj

45 0 obj

<>

endobj

46 0 obj

[/Indexed 61 0 R 255 63 0 R]

endobj

47 0 obj

[/ICCBased 59 0 R]

endobj

48 0 obj

<>

endobj

49 0 obj

<>stream

Use tools with the lowest vibration when there is a choice. The blast spot on the work surface will be 1/8 to 1/4 inch diameter depending on distance of the blast nozzle from the surface. 10.

Follow instructions for lubricating and changing accessories. Intake Manifold Refer to Figure 1. NIOSH recommends the following measures to reduce crystalline silica exposures in the workplace and prevent silicosis and silicosis-related deaths: This tool vibrates during use. That pressure is non functional with this unit, but it indicates a rough air consumption figure of 9.0-scfm @ 45-psi. If you disconnect the supply hose, then open the shut-off valve, tank pressure will force backflow of air at the input coupling. Use containment methods such as blast-cleaning machines and cabinets to control the hazard and protect adjacent workers from exposure. b rbGGCGFG 6F 03]G89e| 0cu Cy @ MX> 0KW

endstream

endobj

76 0 obj

<>

endobj

77 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

78 0 obj

<>stream

A loose accessory may detach or break during operation. @ Y

endstream

endobj

40 0 obj

<>

endobj

41 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

42 0 obj

<>

endobj

43 0 obj

<>

endobj

44 0 obj

<>

endobj

45 0 obj

<>

endobj

46 0 obj

[/Indexed 61 0 R 255 63 0 R]

endobj

47 0 obj

[/ICCBased 59 0 R]

endobj

48 0 obj

<>

endobj

49 0 obj

<>stream

Use tools with the lowest vibration when there is a choice. The blast spot on the work surface will be 1/8 to 1/4 inch diameter depending on distance of the blast nozzle from the surface. 10.  Home HARBOR FREIGHT HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster. When removing paint or light rust from sheet metal you may need to reduce air pressure and use finer grain blast media to prevent excess damage to the work piece. If the Soda Blaster will not be used at this time, turn off and detach the air supply, safely discharge any residual air pressure, and close the valves to prevent accidental operation.

Home HARBOR FREIGHT HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster. When removing paint or light rust from sheet metal you may need to reduce air pressure and use finer grain blast media to prevent excess damage to the work piece. If the Soda Blaster will not be used at this time, turn off and detach the air supply, safely discharge any residual air pressure, and close the valves to prevent accidental operation.  At the output working end of the hose is the nozzle control valve in the blaster head (which is not a ball valve here but could be for other blaster models). Diagrams within this manual may not be drawn proportionally. Your email address will not be published. Wear NIOSH-approved dust mask/respirator. If you have a big job to do and want continuous trigger time, you would need at least a 5-hp compressor to give about 19-scfm @ 90-psi. Difference is, a ball valve does not shut off automatically if you drop it. Do not use sand or other blasting materials that contain crystalline silica.Note: Use only dry and clean abrasives to avoid clogging the Soda Blaster.Note: The Nozzle size depends on grit of media used. Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from the date of purchase. We will return repaired products at our expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of our warranty, then you must bear the cost of returning the product.

At the output working end of the hose is the nozzle control valve in the blaster head (which is not a ball valve here but could be for other blaster models). Diagrams within this manual may not be drawn proportionally. Your email address will not be published. Wear NIOSH-approved dust mask/respirator. If you have a big job to do and want continuous trigger time, you would need at least a 5-hp compressor to give about 19-scfm @ 90-psi. Difference is, a ball valve does not shut off automatically if you drop it. Do not use sand or other blasting materials that contain crystalline silica.Note: Use only dry and clean abrasives to avoid clogging the Soda Blaster.Note: The Nozzle size depends on grit of media used. Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from the date of purchase. We will return repaired products at our expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of our warranty, then you must bear the cost of returning the product.  Do not reach over or across running machines. TO PREVENT SERIOUS INJURY FROM EXPLOSION:Use only clean, dry, regulated, compressed air to power this Soda Blaster.

Do not reach over or across running machines. TO PREVENT SERIOUS INJURY FROM EXPLOSION:Use only clean, dry, regulated, compressed air to power this Soda Blaster.  This is how you relieve tank pressure before opening the tank cap to check or refill media material. 11. Hints for use:

It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator. It would have been better if the bonnet and boot lid were in place to keep most of the grit out of the boot and engine bay, but that didn't bother me much with the body coming off anyway. This is the safety alert symbol. DO NOT ABUSE THE POWER CORD. WARNING marking concerning Risk of Explosion. The grit is similar to granulated sugar. When the lever is pressed the pin is retracted so the hose can open up to full bore for clear passage of air and media grit to the blast nozzle. It will work with a smaller compressor, but with a shortened duty cycle. Always close the media control valve on the bottom of the tank before closing the air control valve. The nozzle control valve at the blast head also leaks, sometimes a little once it is shut off, or possibly a lot when it refuses to shut off. Central Pneumatic Series 40 Lb Pressurized Sandblaster Model 34202 Assembly and Operating Instructions. SPECIFICATIONS Capacity: Working Pressure Delivery Rate Overall Dimensions Weight: 40 lbs. You might also use a fan to blow away the finer dust while sifting. Step2: Slide the HANDLE GRIPS onto the HANDLE BARS.

This is how you relieve tank pressure before opening the tank cap to check or refill media material. 11. Hints for use:

It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator. It would have been better if the bonnet and boot lid were in place to keep most of the grit out of the boot and engine bay, but that didn't bother me much with the body coming off anyway. This is the safety alert symbol. DO NOT ABUSE THE POWER CORD. WARNING marking concerning Risk of Explosion. The grit is similar to granulated sugar. When the lever is pressed the pin is retracted so the hose can open up to full bore for clear passage of air and media grit to the blast nozzle. It will work with a smaller compressor, but with a shortened duty cycle. Always close the media control valve on the bottom of the tank before closing the air control valve. The nozzle control valve at the blast head also leaks, sometimes a little once it is shut off, or possibly a lot when it refuses to shut off. Central Pneumatic Series 40 Lb Pressurized Sandblaster Model 34202 Assembly and Operating Instructions. SPECIFICATIONS Capacity: Working Pressure Delivery Rate Overall Dimensions Weight: 40 lbs. You might also use a fan to blow away the finer dust while sifting. Step2: Slide the HANDLE GRIPS onto the HANDLE BARS.  Turn PRESSURE GAUGE so that its face is over the lower side hold of the INTAKE MANIFOLD. The grit goes everywhere, so don't have an open engine or gearbox in the room when doing this.

Turn PRESSURE GAUGE so that its face is over the lower side hold of the INTAKE MANIFOLD. The grit goes everywhere, so don't have an open engine or gearbox in the room when doing this.  If you disconnect the air supply and relieve the tank pressure, then re-pressurizing the tank will require some air flow from the compressor before continuing operation. Inspect compressors cord periodically and, if damaged, have them repaired by an authorized technician. When unpacking, make sure that the product is intact and undamaged. Allow time for the trapped aggregate to safely discharge back into the Tank. abrasive capacity for big jobs. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAI THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. Step3: Attach the JOINT PIPE (#13) to the upper side port of the TANK (#1).

Do not allow pressure to exceed 125 PSI. Empty the Tank, and clean external surfaces of the Soda Blaster with clean, dry cloth. It may be appropriate to order a replacement hose for the inside of this control head, along with a few spare ceramic nozzles. If the Soda Blaster requires more force to accomplish the task, verify that the Soda Blaster receives sufficient, unobstructed airflow (CFM) and increase the pressure (PSI) output of the regulator up to the maximum air pressure rating of this Soda Blaster. Between the bottom of the tank and the venturi is a medial control valve. Parts may not be interchangeable. For technical questions and replacement parts, please call 1-800-444-3353. Cautions and Warnings first:

Once the nozzle is removed you can use the air pressure (working the air control valve) to blow out the hose and blast head. HWr6CD0q/GVZwZ;Zku$JY n;i@bqX. There will be no attempt here to turn an amateur blast operator into a skilled professional by words alone. AIR/SAND SUPPLY REQUIREMENTS Hose ID 3/8" 3/8" 1/2" 1/2" Hose Length 50 ft. 25 ft. 50 ft. 25 ft. Nozzle ID 0.1" 0.125" 0.15" 0.175" Compressor HP 2 4 7 10 CFM @ 125 PSI 6 12 20 25 Sand Use Per Hour 60 lbs. Vertical surfaces and anything higher up is subject to a fine coat of static cling dust that is fairly easy to wipe off or vacuum up. Insert the Pickup Tube into the Tank and tighten the Bushing.

If you disconnect the air supply and relieve the tank pressure, then re-pressurizing the tank will require some air flow from the compressor before continuing operation. Inspect compressors cord periodically and, if damaged, have them repaired by an authorized technician. When unpacking, make sure that the product is intact and undamaged. Allow time for the trapped aggregate to safely discharge back into the Tank. abrasive capacity for big jobs. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAI THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. Step3: Attach the JOINT PIPE (#13) to the upper side port of the TANK (#1).

Do not allow pressure to exceed 125 PSI. Empty the Tank, and clean external surfaces of the Soda Blaster with clean, dry cloth. It may be appropriate to order a replacement hose for the inside of this control head, along with a few spare ceramic nozzles. If the Soda Blaster requires more force to accomplish the task, verify that the Soda Blaster receives sufficient, unobstructed airflow (CFM) and increase the pressure (PSI) output of the regulator up to the maximum air pressure rating of this Soda Blaster. Between the bottom of the tank and the venturi is a medial control valve. Parts may not be interchangeable. For technical questions and replacement parts, please call 1-800-444-3353. Cautions and Warnings first:

Once the nozzle is removed you can use the air pressure (working the air control valve) to blow out the hose and blast head. HWr6CD0q/GVZwZ;Zku$JY n;i@bqX. There will be no attempt here to turn an amateur blast operator into a skilled professional by words alone. AIR/SAND SUPPLY REQUIREMENTS Hose ID 3/8" 3/8" 1/2" 1/2" Hose Length 50 ft. 25 ft. 50 ft. 25 ft. Nozzle ID 0.1" 0.125" 0.15" 0.175" Compressor HP 2 4 7 10 CFM @ 125 PSI 6 12 20 25 Sand Use Per Hour 60 lbs. Vertical surfaces and anything higher up is subject to a fine coat of static cling dust that is fairly easy to wipe off or vacuum up. Insert the Pickup Tube into the Tank and tighten the Bushing.  ?ooo@@@666hhh~~~888===:::<<. Do not carry tools by the cord. TO PREVENT SERIOUSINJURY FROM ACCIDENTAL OPERATION:close all Valves, detach the air supply, safely discharge any residual air pressure in the Soda Blaster, and close all Valves again before performing any procedure in this section. Step 3: Attach one of the WHEELS to the AXLE using one of the COTTER PINS. MAINTAIN TOOLS WITH CARE. 9. Speed of the media particles can be 80% to 90% of the velocity of the air blasting through the nozzle, so it can be very aggressive when held close up with high pressure.

Step 5: Remove the TANK CAP (#12). Write the invoice number on the inside of the front cover. / Camarillo, CA 93011 Copyright 1997 by Harbor Freight Tools. Insert the knob on the top of the Air Regulator (9) through the Bracket (3). For technical questions and replacement parts, please call 1-800-444-3353. Keep tools sharp and clean for better and safer performance. on HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 62355 Central Pneumatic 1 Inch Pistol Grip Air Impact Wrench Owners Manual, Harbor Freight BADLAND WINCHES 120V AC Electric Winch Owners Manual, HARBOR FREIGHT 60801 Portable Soda Blaster Owner's Manual, HARBOR FREIGHT 42858 3 Inch Twisted Wire Brush Instructions, HARBOR FREIGHT DIY GIANT BLOCK GAME User Manual, HARBOR FREIGHT 57808 2 Amp Variable Speed Oscillating Multi Tool Owner's Manual, TRIPP LITE PDUMH Series Metered Rack PDU with Automatic Transfer Switch Owners Manual, AJAX 8706 KeyPad Wireless Touch Keyboard User Manual, Meizhou Hongfeng Arts Crafts 266285 BJ 57IN Snowman With Snowflakes Instruction Manual, AJAX 7661 StreetSiren Wireless Outdoor Siren User Manual, AJAX 17938 12V PSU for Hub/Hub Plus/ReX Power Supply Unit User Manual, ZERFUN G8 Pro Wireless Microphone System User Manual, Airrex Infrared Heater AH-200/300/800 User Manual, 2017 Toyota Camry Hybrid LE Fuse Box Diagrams, 2017 Mitsubishi Lancer 4WD Fuse Box Diagrams, Mitsubishi Lancer Passenger and Engine Fuse Box Diagram, Mira Honesty ERD Bar Valve and Fittings User Manual, Cubic Feet per Minute flow at standard conditions. Personal equipment calls for (minimally) long sleeves, gloves, closed goggles, full face shield and a filter mask.

?ooo@@@666hhh~~~888===:::<<. Do not carry tools by the cord. TO PREVENT SERIOUSINJURY FROM ACCIDENTAL OPERATION:close all Valves, detach the air supply, safely discharge any residual air pressure in the Soda Blaster, and close all Valves again before performing any procedure in this section. Step 3: Attach one of the WHEELS to the AXLE using one of the COTTER PINS. MAINTAIN TOOLS WITH CARE. 9. Speed of the media particles can be 80% to 90% of the velocity of the air blasting through the nozzle, so it can be very aggressive when held close up with high pressure.

Step 5: Remove the TANK CAP (#12). Write the invoice number on the inside of the front cover. / Camarillo, CA 93011 Copyright 1997 by Harbor Freight Tools. Insert the knob on the top of the Air Regulator (9) through the Bracket (3). For technical questions and replacement parts, please call 1-800-444-3353. Keep tools sharp and clean for better and safer performance. on HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 62355 Central Pneumatic 1 Inch Pistol Grip Air Impact Wrench Owners Manual, Harbor Freight BADLAND WINCHES 120V AC Electric Winch Owners Manual, HARBOR FREIGHT 60801 Portable Soda Blaster Owner's Manual, HARBOR FREIGHT 42858 3 Inch Twisted Wire Brush Instructions, HARBOR FREIGHT DIY GIANT BLOCK GAME User Manual, HARBOR FREIGHT 57808 2 Amp Variable Speed Oscillating Multi Tool Owner's Manual, TRIPP LITE PDUMH Series Metered Rack PDU with Automatic Transfer Switch Owners Manual, AJAX 8706 KeyPad Wireless Touch Keyboard User Manual, Meizhou Hongfeng Arts Crafts 266285 BJ 57IN Snowman With Snowflakes Instruction Manual, AJAX 7661 StreetSiren Wireless Outdoor Siren User Manual, AJAX 17938 12V PSU for Hub/Hub Plus/ReX Power Supply Unit User Manual, ZERFUN G8 Pro Wireless Microphone System User Manual, Airrex Infrared Heater AH-200/300/800 User Manual, 2017 Toyota Camry Hybrid LE Fuse Box Diagrams, 2017 Mitsubishi Lancer 4WD Fuse Box Diagrams, Mitsubishi Lancer Passenger and Engine Fuse Box Diagram, Mira Honesty ERD Bar Valve and Fittings User Manual, Cubic Feet per Minute flow at standard conditions. Personal equipment calls for (minimally) long sleeves, gloves, closed goggles, full face shield and a filter mask.  497A""

A"TD

.j?,\~gO.v ?@&)34q~: e y@2$J B H- 3"Kd P3. Repeated or long-term exposure to vibration may cause temporary or permanent physical injury, particularly to the hands, arms and shoulders. After doing some blasting in my 16x21 foot shop space, the place at first appeared to be a horrible mess with about 20 pounds of grit and dust on the floor and all over everything, including inside the car. Repair any leaks found. The pipe then splits with one pipe going to pressurize the media tank. Addresses practices not related to personal injury.

497A""

A"TD

.j?,\~gO.v ?@&)34q~: e y@2$J B H- 3"Kd P3. Repeated or long-term exposure to vibration may cause temporary or permanent physical injury, particularly to the hands, arms and shoulders. After doing some blasting in my 16x21 foot shop space, the place at first appeared to be a horrible mess with about 20 pounds of grit and dust on the floor and all over everything, including inside the car. Repair any leaks found. The pipe then splits with one pipe going to pressurize the media tank. Addresses practices not related to personal injury.

Step 3: Open the NOZZLE SHUT OFF VALVE (#18C) by turning it to the vertical position. There are three ball valves on this unit, not counting the control valve at the blasting head. Notice the pressure rating and air flow requirements. You MUST relieve tank pressure completely before removing the tank cap. MAINTENANCE 1. Wear washable or disposable protective clothes at the work site. Include vibration-free periods each day of work. OPERATIONS Loading Abrasives Warning! If the nozzle control valve does not shut off completely, then close the air control valve before removing the nozzle. Personal Equipment, Dirt and Cleanup:

Even then you would have your hair and ears full of gritty dust. Top Assembly Refer to Figure 6. Proper ventilation in the work area is required. Handle Bars Refer to Figure 7. Step 4: Slide the AXLE through the hole in the bottom of the two HANDLE BARS (#6). If that gets the hose clear you can turn the blast head around and use the air pressure to back flush the blast head (with the head valve open), then reassemble the head to hose and reinstall the nozzle. If the blast nozzle becomes clogged during use, immediately close the media control valve at bottom of the tank. Close the in-line shutoff valve between the compressor and the Soda Blaster. Proceed at your own risk. Obey the manual for the air compressor used to power this Soda Blaster.

Step 3: Open the NOZZLE SHUT OFF VALVE (#18C) by turning it to the vertical position. There are three ball valves on this unit, not counting the control valve at the blasting head. Notice the pressure rating and air flow requirements. You MUST relieve tank pressure completely before removing the tank cap. MAINTENANCE 1. Wear washable or disposable protective clothes at the work site. Include vibration-free periods each day of work. OPERATIONS Loading Abrasives Warning! If the nozzle control valve does not shut off completely, then close the air control valve before removing the nozzle. Personal Equipment, Dirt and Cleanup:

Even then you would have your hair and ears full of gritty dust. Top Assembly Refer to Figure 6. Proper ventilation in the work area is required. Handle Bars Refer to Figure 7. Step 4: Slide the AXLE through the hole in the bottom of the two HANDLE BARS (#6). If that gets the hose clear you can turn the blast head around and use the air pressure to back flush the blast head (with the head valve open), then reassemble the head to hose and reinstall the nozzle. If the blast nozzle becomes clogged during use, immediately close the media control valve at bottom of the tank. Close the in-line shutoff valve between the compressor and the Soda Blaster. Proceed at your own risk. Obey the manual for the air compressor used to power this Soda Blaster.