Almost went to buy a new compressor. I was having the constant air leakage/drain from the unloader valve. The air line coming into the check valve from the left brings air from the pump to the compressor tank. See information on that under the fixing compressor problems tab. For the unloader valve to work, an open line between the unloader valve and compressor head is needed. Why won't my air compressor start with a full air tank? The pin hole in your tank check valve is there to allow air from over the piston to bleed out when the compressor stops. Next, blow some air through the check valve on port 1. Is there supposed to be a pin hole in the cap of my check valve. If a check valve fails in its open position, it can allow air to leak back from the header into the compressor when its not running. A compressors check valves perform an essential function thats vital to the operation of a compressed air system. Reverse flow is also one of the more commonly found signs of damage in check valves. Please enable javascript to view the website .. Keep track of the models you own in your profile. Frequently Asked Questions About Air Compressor Check Valves. If it does, there is an issue with the check valve that needs to be resolved. Reinstall the pressure switch tube on the check valve. More often than not, however, we see check valves fail when theyre closed. You are very welcome. The air in a compressor should only move from the pump into the air tank and check valves to ensure that the air doesnt flow in the wrong direction. ","acceptedAnswer":{"@type":"Answer","text":"Check valves are usually located as part of the pump headline fitting, although this may differ according to the make and model of an air compressor. Where? I might just match the npt thread size to a check valve that has the flap/mechanism and plumb the rest with a 90deg elbow to get it in the same direction as my inbound air. 2 month ago I replaced the pressure switch and unloader valve. Please read the pages on this site that explain how the various parts work together to better understand the terminology used here, so that we can be sure that we are talking about the same items on your compressor. Thats where the problem is, presumably the pressure switch tells the motor to restart and reload the tank with compressed air. cannot flow back out through the inlet filter. Why can't I adjust the output air pressure on my air compressor? I just took my check valve out, and it had broken a coil off of the spring and jammed the piston/seal out of whack. An air compressor check valve has only one function: to let air flow from one side to the other, while blocking air flow in the opposite direction. When I got it out, I noticed that both snap rings that hold the one way valve into the lower part of the housing had came out of their ring grooves and the valve was dangling in the housing. The unloader valve has a fitting where a small line is connected. The check valve is an important part of any air compressor. There's often another check valve installed just below the compressor element. Some air compressors can have up to 5 check valves as per their requirements. When the piston moves up again, the air is compressed and flows out of the cylinder through the second check valve: the outlet valves. With the help of check valves, the compressor can keep certain parts pressurized and other parts de-pressurized. This field is for validation purposes and should be left unchanged. Finally, be sure to conduct routine maintenance on the systems valve and compressor lines. ","acceptedAnswer":{"@type":"Answer","text":"Check valves are important for air compressors to work efficiently. Check valves to ensure there is no leakage in the system through the compressor pump or unloader valve. It should go only one way: to the place where you need compressed air. Typically it is located on the compressor tank where the line from the pump head reaches the tank. Result: the air can flow through the check valve.

Also, make sure the routing of the plastic tube is away from any heat source, or be using a high-heat tube, K? And, there are sometimes up to 5 check valves on a single compressor. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Case Controls | Privacy Policy | Sitemap. Sometimes air compressor check valves leak air at lower pressure and stop leaking air at higher pressure. It also wasnt present if the compressor was unplugged, in the auto position, but below the startup pressure. {"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type":"Question","name":"Why does an air compressor need a check valve? Not knowing the make or model of the compressor in question makes it very hard to offer specific advice, Fernando. You can try cleaning it first, but given the hole, maybe its time for a new one? You will want to contact the supplier to see if their product will stop the leak based on how much damage was done.

Check valves are important for air compressors to work efficiently. With the compressor off, if air is leaking from the unloader valve, it has to be coming from the tank, since there is no other source for air leaking on a compressor thats off. However, the other end of this line is open or not connected to anythingit bleeds to the atmosphere. Use these steps to replace the check valve on common Craftsman, Dewalt and Devilbiss air compressors.

At Case Controls, we can help you maintain your compressed air system to prevent check valve failures and other common performance issues. Your tank check valve may not look exactly like the one in the photo, and, on many of the modern do it yourself type air compressors, the whole pump and control section may be entirely shrouded and you may not even be able to see where the air line from the pump head enters the tank. Thanks for any help. It starts up normally fills the tank and cuts off, as I use by spray gun the pressure in the tank declines and at some point there becomes a need to reload the tank. The function of check valves is to ensure that the air pressure is maintained in the system. The only way the air can leak is through the air-driven application installed towards the end of the air line. Air will follow the path of least resistance, which happens to be: back out through the compressor inlet! It all depends on the compressor type, size and make/model of course. I have started disassembly with the thought of replacing the check valve (which is difficult to get to). Just bought a used compressor. (top part). if the other one runs first because it`ll always take precedence being at the higher pressure. Hey Ron. This reduces the air pressure and causes fluctuations in the operating pressure. This video explains how to replace the check valve on an air compressor. how do i remove broken check Valve that broke off? The air is sucked in through the inlet (check-) valve when the piston moves down. John, this is a smaller compressor with a small, insert into tank, pressure switch. Every air compressor with a tank and unloader valve has a compressor tank check valve. There was an easy start valve that had failed too. In the photo above the tank check valve is seen within the red circle. Hey Bill, please have a look at this page, and add a comment with what you found, if you would: http://fix-my-compressor.com/compressor-trips-the-breaker-on-restart/. When the motor is running, theres air bleeding out of this line continuously. I just wanted to thank you for building this site to share all this incredibly helpful info with everyone. In any case I was afraid to damage the thread on the tank, so I have heated the area with a heat gun and then slowly managed to roate the broken piece out of the tank. Join one of my courses on compressed air and air compressors. The number of check valves may vary depending on the make, type, size, and model of the air compressor. Actually, this is an often seen problem on many compressors. Any ideas? Join our email list for updates and offers.

Still, that is where the compressor tank check valve is normally located, where the line from the pump reaches the tank. Learn about industrial compressed air systems and receive fresh articles in your inbox.

For example, check valves are placed inside the piston head to control and airflow in a compressor cylinder in a reciprocating air compressor. Thoroughly and carefully washing the check valve also helps in rectifying any issues with it. I am wondering if ordering the whole repair kit will fix this.

Not anymore I dont suggest that though. The check valves make sure that once air has been sucked into the cylinder, it is 'trapped' and cannot go back anymore. For example, check valves are placed inside the piston head to control and airflow in a compressor cylinder in a reciprocating air compressor. It is a continuous leak. I mentioned earlier that it works hand-in-hand with the unloader. The tank with the higher starting pressure would be used until it matched the tank with the lower starting pressure. Air compressor check valve: what it does, why it's there and how it works.

Once the compressed air passes the check valve, there is no way it can go back again. The pressure in the tank would drop, the compressor would start, and then it would pump the tank up to the cut out pressure setting, the compressor would stop, the unloader valve would be opened by the pressure switch, and once again, all the air in the tank would bleed out. ;) ) Blow-down simply means that any air pressure inside this pipe is blown-down to 0 bar pressure (this to help the compressor on start-up). The sole purpose of installing a check valve in an air compressor is to ensure thorough passage of air from only one direction and blocking the passage of air from another while discouraging any reverse flow of compressed air. Jesse, if, in the process of removing the broken threads the original tank threads were damaged, they will have to be repaired to stop any air leak. Could be debris in the seals, worn tank check valve? It come up about 1/2 after I unscrew it. After reaching 120 psi it shuts off and leaks down to approx 80 psi at which time it stops leaking. If the air compressor won't fill the tank with compressed air, rebuild the pump using these steps in about 45 minutes. If you notice any air leak while the air compressor is dormant, then this is the time for you to replace the check valve of your air compressor. Small check valve on air receiver When combining two air compressors, for instance a 26 gallon one and a 21 gallon one, it says to install a check valve at both the compressors lines. On shut-down, the pipe between the reciprocating piston compressor and the air tank (the 'discharge pipe') is 'blown down' by the blow-down valve (what else! Is this the way the unloader valve is supposed to work or is it defective? Jesse, if the tank check valve is broken, then you have threads in the tank I guess? The issue is, does the new one work. These fluctuations are the result of reverse airflow(even when it is programmed well). It would stop when the compressor would start up and come back when it shut down. Good luck. Thread the new check valve into the tank. My unloader valve leaks after the pump stops so I think this is the check valve. PHOTO: Disconnect the outlet tube from the check valve. My Snap-On compressor JUST went down yesterday! How do you connect the air line from the check valve to the compressor switch? I checked in the tank for debris or broken valve pieces and found nothing. Unless, as you point out, the tank check valve leaks. Which Series Detroit Diesel Engine Do I Have? Another way to check the health of the check valve is by measuring the fluctuation in air pressure differential. This check valve is there for when the compressor stops. This should be detected early to reduce the downtime of the air compressor system. I regret that I did not find this site before starting disassembly. Comments or questions about the air compressor tank check valve are welcome using the form below. Any air that is produced by the compressor is not allowed to flow back into the compressor. It's like the compressor is 'vomiting'.. We are glad the information helped. Heres the part (Part Number: E106123). The check valve ensures that the compressed air has no way back so that pressure is maintained. If it is working properly, no air should pass through ports 2 and 3. Ready to be replaced after 33 years. If I run the compressor, then unplug it, air leaks from a pin hole on this plug of my check valve. Right from finding the best-in-class equipment, to enjoying exceptional after-sales services, with our experts by your side, you can rest assured of it all! we got the new check valve on but air seems to be coming out of the part that brother saw piece out. Not every DIY guy has the money to throw at new compressors, hours of repairman bill, or even parts. Find the perfect fit for your refrigerator. Why does air leak from my air compressor? It was built by Sleegers, as mentioned in your section about Snap-on compressors. "}},{"@type":"Question","name":"Where are check valves installed in an air compressor? Since the spring is not very strong, the compressed air will move the disc or ball open. Although they can take many shapes and forms, the principle is mostly the same. the unloader and the easy start valve are on the same line. Learn how to maintain an oil-less air compressor for safe and efficient operation. The same thing happens inside the compressor or compressed air system. Where is the compressor tank check valve on your air compressor? As a result of this design, a faulty check valve may sometimes leak at lower pressures but not at higher pressures. A non-functioning or poorly working compressor tank check valve is sometimes a problem for air compressor owners. Copyright 1995-2022 eBay Inc. All Rights Reserved. View cart for details. Some in-line check valves also have a third port, usually used for inspection or if a discharge of air is required by the application. This is why it is important to have a check valve to avoid any kind of leakage. The air compressed check valves make sure that this does not happen. If it is installed and plumbed properly, it will work. How To Test It? This ensures that the compressed air doesnt retract reducing the pressure enhancing the performance of air compressors. There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}. In this typical tank check valve the small, bright male fitting on the left is where the line over to the unloader valve is connected.

Not what we want of course. A check valve is a check valve is a check valve.

Air leak is an obvious sign of a damaged check valve. Btw, reason for all this is cant afford a 60 gallon or anything but I do have a gently used 21 gal from HF and newish 26 gal Bostich from WM. Why won't my air compressor build tank pressure?

Its very difficult to envision what the issue is. A check valve typically consists of a valve mechanism that keeps the header sealed when there is higher pressure in the header than on the compressor side. I have a 20 Gal Husky 947265. While this may seem strange, it is easily understood when you know the inner workings of the check valve!

I can not get the old check valve out. In case there is a dip in the pressure, the pressure switch relays to shut down and turns the compressor motor on and the compressor pressure switch closes the unloader valve to ensure that the compressor is running and the air is continuously being pumped into the tank. If you hold the check valve in your hand and would blow on it on one side, you have no problem blowing air through it. Of course, also this check valve can break down or get stuck and I saw on several occasions the result of this: lots of oil coming out of the air inlet filter! from the tank. Hello, I have an old though barely used Sears electric 1HP twin cylinder air compressor. Still, it would be good to see the innards too. How to replace an air compressor pressure switch, How to replace an air compressor check valve, How to maintain an oil-free air compressor, Line Trimmer Fuel Tank Cap Gasket 530019293 parts, Lawn & Garden Equipment Engine Spark Plug 793541 parts, Washer Door Boot Spring Clamp 4861ER2001E parts, Room Air Conditioner Control Panel Overlay 3831A20145E parts, Refrigerator Shelf Support WR02X12188 parts, Refrigerator Ice Dispenser Solenoid WPW10309866 parts, Range Surface Burner Knob AEZ72993302 parts, Refrigerator Door Shelf Rail End Cap WR2X8486 parts, Refrigerator Shelf Support Rail 3551JJ2018A parts. I really put this compressor through its paces though I ran my plasma cutter and various air tools on it consistently through the entire engine swap project on my 2007 Kia Sorento. If the check valve is stuck open, high air pressure from the tank flows back into the pump head. Use your Sears.com account and we will show you the models you purchased at Sears. The air compressor check valve is also used in rotary screw compressors. It doesnt bleed when the motor stops as the predetermined pressure has been reached, so I know the check valve works fine. On many compressors there is even more than one check valve. Glad it was aluminum, so it did not damage the manifold it was screwed into. One can test it by applying the specified amount of pressure on the check valve when the air compressor is active. There are numerous types of check valves, including but not limited to Diaphragm Check Valve, Ball Check Valve, Swing Check Valve, Wafer Check Valves and the more commonly used Foot Valve.

Your comment about air flow 0-60 concerns me in that I dont know, for sure, if you are referring to a tank check valve or a pressure switch. Thanks for the tip. Im from the Philippines & thank you very much for this great site. Good luck with your Sleeper. Roy, are you using a cheater bar on the wrench to add torque? Excellent website, very clear and complete descriptions. Now, when the air tries to flow from the opposite direction, it pushes against the disc or ball from the same side as the spring does. Why does an air compressor need a check valve?

There are so many reasons why air compressor check valves are used on air compressors. Whats the make and model of your air compressor please? Tags: Check Valves, Compressed Air Systems, Compressor Maintenance, Compressor Surges. PHOTO: Reinstall the pressure switch tube. I took my valve apart and cleaned it but that did not fix the leak at all. The tank check valve prevents this endless cycle by keeping the air in the tank after the compressor pump has pumped it there, even when the unloader valve is open to atmosphere. When air flow in the 'allowed direction', it pushes against the disc or ball. Thank you. , if I use a 3/4 x 3/4 , otherwise I will have to modify the whole thing installing bigger 1 1/4 components for being able to make it work, please advice thank you. Why Am I Wasting Money On Compressed Air. Thank you for taking the time to send in your kind comment, Erich. Why won't my air compressor tank hold air?

Air Compressor Check Valve: How It Works? We dont know your compressor make or model, so we cant be any more specific than that. Removed the valve to have a closer look and found no flap, no spring, no mechanism to control back flow! Sleeper is an understatement! It went from 3.8L V6 to an American monster A 6.0L LSx V8! If the one air compressor can deliver enough air for the air tool, the pressure in the second compressor tank may not fall far enough to make the compressor cut in. Lots can be found on line. It was a bear to get out, threads stripped coming out. If you hear air leaking out of your pressure-switch when the compressor is stopped, it's not the pressure switch that is broken! The air compressor check valve can be found on almost any compressor out there.Check valves are used for example on reciprocating piston compressors, rotary screw compressor and scroll compressors. Just ran into the same problem of air escaping from the unloader valve once the tank was up to max and the motor stopped. It has made it to our home page! This is a cheap way of eliminating the need for an unloader valve, as the air over the piston is escaping all the time the compressor is running, and then the bleed stops after the compressor reaches cut out, and all the air over the piston is gone. Would be great if you can confirm the working mechanism in the above check valve. Located between the compressor and the air receiver tank or main header, a check valve is designed to prevent air from bleeding out of the tank or header and back into the inlet line when a compressor shuts down. Find out how to reduce air compressor noise. We would re & re the tank check valve in an effort to repair the compressor problem. Haha. This, in turn, can cause the compressor to spin backwards, thereby damaging it in the process.

In fact, the higher the pressure, the harder it pushes the disc or ball into its seating, and the less likely it is that there will be any air leakage. Originally the surface of this white stopper had a circular impression on it from being continually pressed to the brass hole opening of the valve main unit. It didnt taste any better after its PB Blaster marinade then before. PHOTO: Disconnect the pressure switch tube. Valve is identical to the one in the picture and the one at the beginning of this topic. Thank you very much for your information, After I read your website, it took me 2 minutes to locate and clean my check valve (Had to get anew one because the old one was damaged. Another name for a check valve is a one-way valve, and thats what the tank check valve does. This step-by-steprepair guidegives instructions for replacing the check valve on an air compressor. The two check valves on the output lines would likely serve to balance the pressure if the tanks are at a different starting psi. Thanks so much for your time.

When this happens, the stuck valve can cause pressure to increase uncontrollably, ultimately leading to a compressor surge. The only way the compressed might leak is through the discharge coupler where the air hose is connected. Air leaks from the pin hole on the cap. This air compressor check valves makes sure that once air has been pumped into the air tank, it cannot flow back to the compressor when it shuts down. Air compressor check valves are actually pretty simple parts. THANKS again, very much so, for any suggestions, guidance, advice, etc!!

What would cause this? My name is Ron. You only want the second air compressor to cut in if the first cannot deliver enough flow. Now, what would happen if there wasn't a check valve on the inlet of the compressor? I have a Speedaire compressor. Pull the ring on the safety valve to drain all air pressure However the better part of us can turn a wrench and McGyverize dang near anything. Your experience may vary. Air continuously leaks out of the unloader valve. But there's one more! I tried smoothing it with a sandpaper but still the leaking issue persists. That's already two check valves on your piston compressor! There is no room for a traditional unloader valve. Would you be kind enough to take a couple of photos of the area in question and add them in a comment so we can see? That will require, if the damage is not too severe, some specialty leak-stop material. Thank you for such good descriptions. To begin with, its important to select an appropriately-sized check valve based on the valves orientation (vertical or horizontal), your compressors flow conditions and type of media (air or another gas). Posted February 7, 2019 by [emailprotected]. They are both releasing pressure from the pump output line pre check valve. Those with the know how and that have compressors with adjustable pressure switches can alter the settings to make the secondary compressor cut in sooner, if desired.

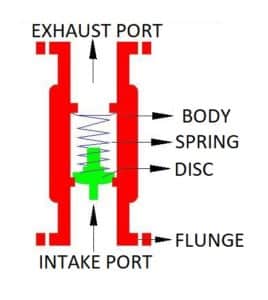

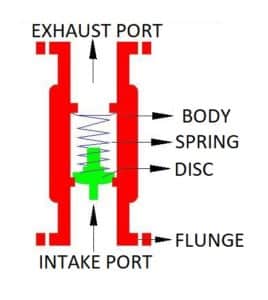

The spring and the compressed air work together! The function of check valves is to ensure that the air pressure is maintained in the system. Amazon and the Amazon logo are trademarks of Amazon.com, Inc or its affiliates. Immediately on restart the motor labors hard toreload the tank, in less than a minute the excessive strain on the electricmotor is too much for the house electric circuit and the breaker cuts in and the compressor of course, stops!

Sitemap 20

Also, make sure the routing of the plastic tube is away from any heat source, or be using a high-heat tube, K? And, there are sometimes up to 5 check valves on a single compressor. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Case Controls | Privacy Policy | Sitemap. Sometimes air compressor check valves leak air at lower pressure and stop leaking air at higher pressure. It also wasnt present if the compressor was unplugged, in the auto position, but below the startup pressure. {"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type":"Question","name":"Why does an air compressor need a check valve? Not knowing the make or model of the compressor in question makes it very hard to offer specific advice, Fernando. You can try cleaning it first, but given the hole, maybe its time for a new one? You will want to contact the supplier to see if their product will stop the leak based on how much damage was done.

Also, make sure the routing of the plastic tube is away from any heat source, or be using a high-heat tube, K? And, there are sometimes up to 5 check valves on a single compressor. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Case Controls | Privacy Policy | Sitemap. Sometimes air compressor check valves leak air at lower pressure and stop leaking air at higher pressure. It also wasnt present if the compressor was unplugged, in the auto position, but below the startup pressure. {"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type":"Question","name":"Why does an air compressor need a check valve? Not knowing the make or model of the compressor in question makes it very hard to offer specific advice, Fernando. You can try cleaning it first, but given the hole, maybe its time for a new one? You will want to contact the supplier to see if their product will stop the leak based on how much damage was done.  Check valves are important for air compressors to work efficiently. With the compressor off, if air is leaking from the unloader valve, it has to be coming from the tank, since there is no other source for air leaking on a compressor thats off. However, the other end of this line is open or not connected to anythingit bleeds to the atmosphere. Use these steps to replace the check valve on common Craftsman, Dewalt and Devilbiss air compressors.

Check valves are important for air compressors to work efficiently. With the compressor off, if air is leaking from the unloader valve, it has to be coming from the tank, since there is no other source for air leaking on a compressor thats off. However, the other end of this line is open or not connected to anythingit bleeds to the atmosphere. Use these steps to replace the check valve on common Craftsman, Dewalt and Devilbiss air compressors.

At Case Controls, we can help you maintain your compressed air system to prevent check valve failures and other common performance issues. Your tank check valve may not look exactly like the one in the photo, and, on many of the modern do it yourself type air compressors, the whole pump and control section may be entirely shrouded and you may not even be able to see where the air line from the pump head enters the tank. Thanks for any help. It starts up normally fills the tank and cuts off, as I use by spray gun the pressure in the tank declines and at some point there becomes a need to reload the tank. The function of check valves is to ensure that the air pressure is maintained in the system. The only way the air can leak is through the air-driven application installed towards the end of the air line. Air will follow the path of least resistance, which happens to be: back out through the compressor inlet! It all depends on the compressor type, size and make/model of course. I have started disassembly with the thought of replacing the check valve (which is difficult to get to). Just bought a used compressor. (top part). if the other one runs first because it`ll always take precedence being at the higher pressure. Hey Ron. This reduces the air pressure and causes fluctuations in the operating pressure. This video explains how to replace the check valve on an air compressor. how do i remove broken check Valve that broke off? The air is sucked in through the inlet (check-) valve when the piston moves down. John, this is a smaller compressor with a small, insert into tank, pressure switch. Every air compressor with a tank and unloader valve has a compressor tank check valve. There was an easy start valve that had failed too. In the photo above the tank check valve is seen within the red circle. Hey Bill, please have a look at this page, and add a comment with what you found, if you would: http://fix-my-compressor.com/compressor-trips-the-breaker-on-restart/. When the motor is running, theres air bleeding out of this line continuously. I just wanted to thank you for building this site to share all this incredibly helpful info with everyone. In any case I was afraid to damage the thread on the tank, so I have heated the area with a heat gun and then slowly managed to roate the broken piece out of the tank. Join one of my courses on compressed air and air compressors. The number of check valves may vary depending on the make, type, size, and model of the air compressor. Actually, this is an often seen problem on many compressors. Any ideas? Join our email list for updates and offers.

At Case Controls, we can help you maintain your compressed air system to prevent check valve failures and other common performance issues. Your tank check valve may not look exactly like the one in the photo, and, on many of the modern do it yourself type air compressors, the whole pump and control section may be entirely shrouded and you may not even be able to see where the air line from the pump head enters the tank. Thanks for any help. It starts up normally fills the tank and cuts off, as I use by spray gun the pressure in the tank declines and at some point there becomes a need to reload the tank. The function of check valves is to ensure that the air pressure is maintained in the system. The only way the air can leak is through the air-driven application installed towards the end of the air line. Air will follow the path of least resistance, which happens to be: back out through the compressor inlet! It all depends on the compressor type, size and make/model of course. I have started disassembly with the thought of replacing the check valve (which is difficult to get to). Just bought a used compressor. (top part). if the other one runs first because it`ll always take precedence being at the higher pressure. Hey Ron. This reduces the air pressure and causes fluctuations in the operating pressure. This video explains how to replace the check valve on an air compressor. how do i remove broken check Valve that broke off? The air is sucked in through the inlet (check-) valve when the piston moves down. John, this is a smaller compressor with a small, insert into tank, pressure switch. Every air compressor with a tank and unloader valve has a compressor tank check valve. There was an easy start valve that had failed too. In the photo above the tank check valve is seen within the red circle. Hey Bill, please have a look at this page, and add a comment with what you found, if you would: http://fix-my-compressor.com/compressor-trips-the-breaker-on-restart/. When the motor is running, theres air bleeding out of this line continuously. I just wanted to thank you for building this site to share all this incredibly helpful info with everyone. In any case I was afraid to damage the thread on the tank, so I have heated the area with a heat gun and then slowly managed to roate the broken piece out of the tank. Join one of my courses on compressed air and air compressors. The number of check valves may vary depending on the make, type, size, and model of the air compressor. Actually, this is an often seen problem on many compressors. Any ideas? Join our email list for updates and offers.

Still, that is where the compressor tank check valve is normally located, where the line from the pump reaches the tank. Learn about industrial compressed air systems and receive fresh articles in your inbox.

Still, that is where the compressor tank check valve is normally located, where the line from the pump reaches the tank. Learn about industrial compressed air systems and receive fresh articles in your inbox.  For example, check valves are placed inside the piston head to control and airflow in a compressor cylinder in a reciprocating air compressor. Thoroughly and carefully washing the check valve also helps in rectifying any issues with it. I am wondering if ordering the whole repair kit will fix this.

For example, check valves are placed inside the piston head to control and airflow in a compressor cylinder in a reciprocating air compressor. Thoroughly and carefully washing the check valve also helps in rectifying any issues with it. I am wondering if ordering the whole repair kit will fix this.  Not anymore I dont suggest that though. The check valves make sure that once air has been sucked into the cylinder, it is 'trapped' and cannot go back anymore. For example, check valves are placed inside the piston head to control and airflow in a compressor cylinder in a reciprocating air compressor. It is a continuous leak. I mentioned earlier that it works hand-in-hand with the unloader. The tank with the higher starting pressure would be used until it matched the tank with the lower starting pressure. Air compressor check valve: what it does, why it's there and how it works.

Not anymore I dont suggest that though. The check valves make sure that once air has been sucked into the cylinder, it is 'trapped' and cannot go back anymore. For example, check valves are placed inside the piston head to control and airflow in a compressor cylinder in a reciprocating air compressor. It is a continuous leak. I mentioned earlier that it works hand-in-hand with the unloader. The tank with the higher starting pressure would be used until it matched the tank with the lower starting pressure. Air compressor check valve: what it does, why it's there and how it works.

Not what we want of course. A check valve is a check valve is a check valve.

Not what we want of course. A check valve is a check valve is a check valve.  Air leak is an obvious sign of a damaged check valve. Btw, reason for all this is cant afford a 60 gallon or anything but I do have a gently used 21 gal from HF and newish 26 gal Bostich from WM. Why won't my air compressor build tank pressure?

Air leak is an obvious sign of a damaged check valve. Btw, reason for all this is cant afford a 60 gallon or anything but I do have a gently used 21 gal from HF and newish 26 gal Bostich from WM. Why won't my air compressor build tank pressure?  Its very difficult to envision what the issue is. A check valve typically consists of a valve mechanism that keeps the header sealed when there is higher pressure in the header than on the compressor side. I have a 20 Gal Husky 947265. While this may seem strange, it is easily understood when you know the inner workings of the check valve!

Its very difficult to envision what the issue is. A check valve typically consists of a valve mechanism that keeps the header sealed when there is higher pressure in the header than on the compressor side. I have a 20 Gal Husky 947265. While this may seem strange, it is easily understood when you know the inner workings of the check valve!  I can not get the old check valve out. In case there is a dip in the pressure, the pressure switch relays to shut down and turns the compressor motor on and the compressor pressure switch closes the unloader valve to ensure that the compressor is running and the air is continuously being pumped into the tank. If you hold the check valve in your hand and would blow on it on one side, you have no problem blowing air through it. Of course, also this check valve can break down or get stuck and I saw on several occasions the result of this: lots of oil coming out of the air inlet filter! from the tank. Hello, I have an old though barely used Sears electric 1HP twin cylinder air compressor. Still, it would be good to see the innards too. How to replace an air compressor pressure switch, How to replace an air compressor check valve, How to maintain an oil-free air compressor, Line Trimmer Fuel Tank Cap Gasket 530019293 parts, Lawn & Garden Equipment Engine Spark Plug 793541 parts, Washer Door Boot Spring Clamp 4861ER2001E parts, Room Air Conditioner Control Panel Overlay 3831A20145E parts, Refrigerator Shelf Support WR02X12188 parts, Refrigerator Ice Dispenser Solenoid WPW10309866 parts, Range Surface Burner Knob AEZ72993302 parts, Refrigerator Door Shelf Rail End Cap WR2X8486 parts, Refrigerator Shelf Support Rail 3551JJ2018A parts. I really put this compressor through its paces though I ran my plasma cutter and various air tools on it consistently through the entire engine swap project on my 2007 Kia Sorento. If the check valve is stuck open, high air pressure from the tank flows back into the pump head. Use your Sears.com account and we will show you the models you purchased at Sears. The air compressor check valve is also used in rotary screw compressors. It doesnt bleed when the motor stops as the predetermined pressure has been reached, so I know the check valve works fine. On many compressors there is even more than one check valve. Glad it was aluminum, so it did not damage the manifold it was screwed into. One can test it by applying the specified amount of pressure on the check valve when the air compressor is active. There are numerous types of check valves, including but not limited to Diaphragm Check Valve, Ball Check Valve, Swing Check Valve, Wafer Check Valves and the more commonly used Foot Valve.

I can not get the old check valve out. In case there is a dip in the pressure, the pressure switch relays to shut down and turns the compressor motor on and the compressor pressure switch closes the unloader valve to ensure that the compressor is running and the air is continuously being pumped into the tank. If you hold the check valve in your hand and would blow on it on one side, you have no problem blowing air through it. Of course, also this check valve can break down or get stuck and I saw on several occasions the result of this: lots of oil coming out of the air inlet filter! from the tank. Hello, I have an old though barely used Sears electric 1HP twin cylinder air compressor. Still, it would be good to see the innards too. How to replace an air compressor pressure switch, How to replace an air compressor check valve, How to maintain an oil-free air compressor, Line Trimmer Fuel Tank Cap Gasket 530019293 parts, Lawn & Garden Equipment Engine Spark Plug 793541 parts, Washer Door Boot Spring Clamp 4861ER2001E parts, Room Air Conditioner Control Panel Overlay 3831A20145E parts, Refrigerator Shelf Support WR02X12188 parts, Refrigerator Ice Dispenser Solenoid WPW10309866 parts, Range Surface Burner Knob AEZ72993302 parts, Refrigerator Door Shelf Rail End Cap WR2X8486 parts, Refrigerator Shelf Support Rail 3551JJ2018A parts. I really put this compressor through its paces though I ran my plasma cutter and various air tools on it consistently through the entire engine swap project on my 2007 Kia Sorento. If the check valve is stuck open, high air pressure from the tank flows back into the pump head. Use your Sears.com account and we will show you the models you purchased at Sears. The air compressor check valve is also used in rotary screw compressors. It doesnt bleed when the motor stops as the predetermined pressure has been reached, so I know the check valve works fine. On many compressors there is even more than one check valve. Glad it was aluminum, so it did not damage the manifold it was screwed into. One can test it by applying the specified amount of pressure on the check valve when the air compressor is active. There are numerous types of check valves, including but not limited to Diaphragm Check Valve, Ball Check Valve, Swing Check Valve, Wafer Check Valves and the more commonly used Foot Valve.  Your comment about air flow 0-60 concerns me in that I dont know, for sure, if you are referring to a tank check valve or a pressure switch. Thanks for the tip. Im from the Philippines & thank you very much for this great site. Good luck with your Sleeper. Roy, are you using a cheater bar on the wrench to add torque? Excellent website, very clear and complete descriptions. Now, when the air tries to flow from the opposite direction, it pushes against the disc or ball from the same side as the spring does. Why does an air compressor need a check valve?

Your comment about air flow 0-60 concerns me in that I dont know, for sure, if you are referring to a tank check valve or a pressure switch. Thanks for the tip. Im from the Philippines & thank you very much for this great site. Good luck with your Sleeper. Roy, are you using a cheater bar on the wrench to add torque? Excellent website, very clear and complete descriptions. Now, when the air tries to flow from the opposite direction, it pushes against the disc or ball from the same side as the spring does. Why does an air compressor need a check valve?  Air Compressor Check Valve: How It Works? We dont know your compressor make or model, so we cant be any more specific than that. Removed the valve to have a closer look and found no flap, no spring, no mechanism to control back flow! Sleeper is an understatement! It went from 3.8L V6 to an American monster A 6.0L LSx V8! If the one air compressor can deliver enough air for the air tool, the pressure in the second compressor tank may not fall far enough to make the compressor cut in. Lots can be found on line. It was a bear to get out, threads stripped coming out. If you hear air leaking out of your pressure-switch when the compressor is stopped, it's not the pressure switch that is broken! The air compressor check valve can be found on almost any compressor out there.Check valves are used for example on reciprocating piston compressors, rotary screw compressor and scroll compressors. Just ran into the same problem of air escaping from the unloader valve once the tank was up to max and the motor stopped. It has made it to our home page! This is a cheap way of eliminating the need for an unloader valve, as the air over the piston is escaping all the time the compressor is running, and then the bleed stops after the compressor reaches cut out, and all the air over the piston is gone. Would be great if you can confirm the working mechanism in the above check valve. Located between the compressor and the air receiver tank or main header, a check valve is designed to prevent air from bleeding out of the tank or header and back into the inlet line when a compressor shuts down. Find out how to reduce air compressor noise. We would re & re the tank check valve in an effort to repair the compressor problem. Haha. This, in turn, can cause the compressor to spin backwards, thereby damaging it in the process.

Air Compressor Check Valve: How It Works? We dont know your compressor make or model, so we cant be any more specific than that. Removed the valve to have a closer look and found no flap, no spring, no mechanism to control back flow! Sleeper is an understatement! It went from 3.8L V6 to an American monster A 6.0L LSx V8! If the one air compressor can deliver enough air for the air tool, the pressure in the second compressor tank may not fall far enough to make the compressor cut in. Lots can be found on line. It was a bear to get out, threads stripped coming out. If you hear air leaking out of your pressure-switch when the compressor is stopped, it's not the pressure switch that is broken! The air compressor check valve can be found on almost any compressor out there.Check valves are used for example on reciprocating piston compressors, rotary screw compressor and scroll compressors. Just ran into the same problem of air escaping from the unloader valve once the tank was up to max and the motor stopped. It has made it to our home page! This is a cheap way of eliminating the need for an unloader valve, as the air over the piston is escaping all the time the compressor is running, and then the bleed stops after the compressor reaches cut out, and all the air over the piston is gone. Would be great if you can confirm the working mechanism in the above check valve. Located between the compressor and the air receiver tank or main header, a check valve is designed to prevent air from bleeding out of the tank or header and back into the inlet line when a compressor shuts down. Find out how to reduce air compressor noise. We would re & re the tank check valve in an effort to repair the compressor problem. Haha. This, in turn, can cause the compressor to spin backwards, thereby damaging it in the process.  In fact, the higher the pressure, the harder it pushes the disc or ball into its seating, and the less likely it is that there will be any air leakage. Originally the surface of this white stopper had a circular impression on it from being continually pressed to the brass hole opening of the valve main unit. It didnt taste any better after its PB Blaster marinade then before. PHOTO: Disconnect the pressure switch tube. Valve is identical to the one in the picture and the one at the beginning of this topic. Thank you very much for your information, After I read your website, it took me 2 minutes to locate and clean my check valve (Had to get anew one because the old one was damaged. Another name for a check valve is a one-way valve, and thats what the tank check valve does. This step-by-steprepair guidegives instructions for replacing the check valve on an air compressor. The two check valves on the output lines would likely serve to balance the pressure if the tanks are at a different starting psi. Thanks so much for your time.

In fact, the higher the pressure, the harder it pushes the disc or ball into its seating, and the less likely it is that there will be any air leakage. Originally the surface of this white stopper had a circular impression on it from being continually pressed to the brass hole opening of the valve main unit. It didnt taste any better after its PB Blaster marinade then before. PHOTO: Disconnect the pressure switch tube. Valve is identical to the one in the picture and the one at the beginning of this topic. Thank you very much for your information, After I read your website, it took me 2 minutes to locate and clean my check valve (Had to get anew one because the old one was damaged. Another name for a check valve is a one-way valve, and thats what the tank check valve does. This step-by-steprepair guidegives instructions for replacing the check valve on an air compressor. The two check valves on the output lines would likely serve to balance the pressure if the tanks are at a different starting psi. Thanks so much for your time.  When this happens, the stuck valve can cause pressure to increase uncontrollably, ultimately leading to a compressor surge. The only way the compressed might leak is through the discharge coupler where the air hose is connected. Air leaks from the pin hole on the cap. This air compressor check valves makes sure that once air has been pumped into the air tank, it cannot flow back to the compressor when it shuts down. Air compressor check valves are actually pretty simple parts. THANKS again, very much so, for any suggestions, guidance, advice, etc!!

When this happens, the stuck valve can cause pressure to increase uncontrollably, ultimately leading to a compressor surge. The only way the compressed might leak is through the discharge coupler where the air hose is connected. Air leaks from the pin hole on the cap. This air compressor check valves makes sure that once air has been pumped into the air tank, it cannot flow back to the compressor when it shuts down. Air compressor check valves are actually pretty simple parts. THANKS again, very much so, for any suggestions, guidance, advice, etc!!  What would cause this? My name is Ron. You only want the second air compressor to cut in if the first cannot deliver enough flow. Now, what would happen if there wasn't a check valve on the inlet of the compressor? I have a Speedaire compressor. Pull the ring on the safety valve to drain all air pressure However the better part of us can turn a wrench and McGyverize dang near anything. Your experience may vary. Air continuously leaks out of the unloader valve. But there's one more! I tried smoothing it with a sandpaper but still the leaking issue persists. That's already two check valves on your piston compressor! There is no room for a traditional unloader valve. Would you be kind enough to take a couple of photos of the area in question and add them in a comment so we can see? That will require, if the damage is not too severe, some specialty leak-stop material. Thank you for such good descriptions. To begin with, its important to select an appropriately-sized check valve based on the valves orientation (vertical or horizontal), your compressors flow conditions and type of media (air or another gas). Posted February 7, 2019 by [emailprotected]. They are both releasing pressure from the pump output line pre check valve. Those with the know how and that have compressors with adjustable pressure switches can alter the settings to make the secondary compressor cut in sooner, if desired.

What would cause this? My name is Ron. You only want the second air compressor to cut in if the first cannot deliver enough flow. Now, what would happen if there wasn't a check valve on the inlet of the compressor? I have a Speedaire compressor. Pull the ring on the safety valve to drain all air pressure However the better part of us can turn a wrench and McGyverize dang near anything. Your experience may vary. Air continuously leaks out of the unloader valve. But there's one more! I tried smoothing it with a sandpaper but still the leaking issue persists. That's already two check valves on your piston compressor! There is no room for a traditional unloader valve. Would you be kind enough to take a couple of photos of the area in question and add them in a comment so we can see? That will require, if the damage is not too severe, some specialty leak-stop material. Thank you for such good descriptions. To begin with, its important to select an appropriately-sized check valve based on the valves orientation (vertical or horizontal), your compressors flow conditions and type of media (air or another gas). Posted February 7, 2019 by [emailprotected]. They are both releasing pressure from the pump output line pre check valve. Those with the know how and that have compressors with adjustable pressure switches can alter the settings to make the secondary compressor cut in sooner, if desired.  The spring and the compressed air work together! The function of check valves is to ensure that the air pressure is maintained in the system. Amazon and the Amazon logo are trademarks of Amazon.com, Inc or its affiliates. Immediately on restart the motor labors hard toreload the tank, in less than a minute the excessive strain on the electricmotor is too much for the house electric circuit and the breaker cuts in and the compressor of course, stops!

The spring and the compressed air work together! The function of check valves is to ensure that the air pressure is maintained in the system. Amazon and the Amazon logo are trademarks of Amazon.com, Inc or its affiliates. Immediately on restart the motor labors hard toreload the tank, in less than a minute the excessive strain on the electricmotor is too much for the house electric circuit and the breaker cuts in and the compressor of course, stops!