Thomasnet Is A Registered Trademark Of Thomas Publishing Serves the manufacturing, HVAC, food processing, cold storage, plastic, healthcare, breweries and automotive industries. Serves the food, chemical, pharmaceutical, biotechnology, mining, environmental protection and other industries. So it is especially suitable for the occasion where demands a high cleanliness or short runs but multiple types of product and large quantities of product. Oil from water. Types include T-type inline and straight thru inline separators. SEPCOM Vertical is an innovative screw press solids-liquid separator. In respect of solids discharge they work either discontinuously (e.g.

Weight: - ca. That can mean relatively fine adjustments to compensate for changes in liquid flow and composition. It is suitable for every type of drain: manual, electronic and timed. Welcome to the premier industrial Centrifugal Separators resource. UL listed. B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries. We are here to help!

Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. Available in various modes, sizes and features with 675 and 450 psig maximum working pressure, 1.5 to 118 cfm maximum discharge rate and 15 to 40 oz. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel. Custom manufacturer of metal fabrications & stampings, magnets & plastic products. The later is the next genuine stage in evolution in the separator construction process and works without motor shaft, gear, belts, coupling and motor bearing. Meets ANSI standards. It can be widely applied in the industries such as pharmacy chemical industry, food, printing dyeing industry.

By changing the flowrate, back pressures, bowl rotational speed, and other variables the operator can fine tune the separation. With options for both coarse and fine grinding applications, static separators can be outfitted to any airswept mill. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. This is centrifugation at its most basic. How Big Is An Industrial Centrifuge Separator? Once youve got your mixture of liquids and particles under acceleration, you can exert a great deal of control over how the separation proceeds. But speeding up separation is just the start. Since its foundation by Theodor Naarmann in 1903, conserving resources while ensuring the highest possible quality standards has been a priority for the company. Serves the refrigeration and air conditioning industries. GEA separators are designed for liquid-based applications. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas. The label High-Capacity Closed Circuit Husk Separator

-, {{product.productPrice.formattedPriceMax}}, GEA Westfalia Separator centrifugal separators, GEA Westfalia Separator centrifugal decanters. Filtration by centrifugal force. Outlet opening : - DN 400

With just a few details we will be able to respond to your inquiry. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. Noise absorbers are suitable for use in industrial applications, TV/radio, kennels, churches, music studios, gymnasiums, commercial offices, phone booths and HVAC.

It is suitable for waste wood, railroad sleepers and other wood, waste, scrap and tires as well as car bodies, aluminium and household Zig-zag separator If you have production capacity for suspension separation and centrifugal separation equipment which can be sold on the market, the industrial centrifuge separator will be your suitable choice. Traditionally used with most forms of fine grinding, the double cone separator is applicable for very abrasive or sticky materials. Site of operation: - In the chip suction system A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Water separator / Cyclone separator

Features double O-ring seal, stainless steel and fiberglass support, deep bed multi-wrap borosilicate, polyester needle felt sleeve, and 1/4 to 3 in. This is called three-phase or solid-liquid-liquid separation. Saideli integrates scientific research, sales, and manufacture of centrifuges as well as some dryers and filters. If the dinner conversation has been less than thrilling, you probably gave that dressing a moments consideration and realized that gravity was doing all the work: Given enough time, gravity is always going to sort out mixtures of solid particles and immiscible liquidswith the emphasis on that phrase given enough time.. 1000 Hess Ave, {{#each product.specData:i}} Manufacturer of simplex duplex strainers, transfer valves and positive placement pumps for fuel oil transfer and pipeline service. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Centrifugal separator machines use gravity and mechanical means to separate compounds. Product Description:

Manufacturer of centrifugal separators for closed loop water treatment systems. Process port size is 1 1/2 ins. Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist.

for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality

ISO 9001:2008 certified. Product

or separation for further Zig-Zag air separator is designed for simultaneous dedusting and dry separation of materials into light and heavy fractions by size, density and shape with up to 99% efficiency. The fields of application range from separating processes in the chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, beer, wine, fruit and vegetable juices, as well as the processing of mineral oil and mineral oil products. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. The discs in a disc stack separator are actually a series of cone-shaped plates arranged in a vertical stack inside of the centrifuges rotor bowl. ISO 9001:2000 and ISO 14001:2004 certified. Acoustical and noise control products include acoustic tiles, ceiling tiles, sound barriers, acoustical wall coverings, foam panels, wedges, curtains, blankets, baffles and enclosures. H x 25 ins. As the artificial gravity increases, the time it takes to separate your materials decreases. The Combinator type MTCD is employed in both grain milling and specialty milling for the classification of grain into high-density (heavy) and mixed

Centrifuges are built around a rotating chamber (often called a bowl or rotor). The SEPCOM Micro-filter MFT is a machine for the micro-filtration of slurries from a previous separation process of digestate from biogas generating processes or industrial wastewater. ASTM compliant. With good seal performance, the harmful chemical products will not contact the operator and also the toxic gas will not enter into the air. Advantages

Manufacturer of inverted cone and double cone air separators to meet particular demands of various grinding and milling applications. The optimized classifier wheel design guarantees that very high finenesses can be achieved with only one classifier Width: 380 mm - 2,500 mmFiltration size: 2.6 m - 60 m. Manufacturer of adjustable centrifugal separators. The innovative design of the integrated direct drive also enables the motor to be replaced complete with the drive within only a few hours when maintenance work has to be carried out this is time which is very valuable and which can be used productively elsewhere.

foil and paper separation, for example. Used to capture particles as small as 1 micrometer. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. All Rights Reserved. The impressive reliability record for Pusher Centrifuges is grounded in its sound design, precise engineering, and top-grade construction. {{/each}}. Website Last Modified July 30, 2022.

www.flsmidth.com/en-gb/products/krebs-desan Centrifugal separators. Dust container capacity: 100l. Distributor of centrifugal separators. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. BOGE CC-2 oil-water separators operate with different filter stages, in which coated polypropylene fibres as well Width: 610 mm - 7,100 mmFiltration size: 10 m - 25 m. VFG- CY Pre-separator is special designed for the floor grinding and polishing industry. {{/end}} Length: 1,060 mmWeight: 192 kgWidth: 810 mm. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. The oregano in your Italian dressing settles out in a few minutes. Materials include melamine and polyurethane foam, PVC vinyl and fiberglass.

Suitable for water, waste, microelectronics, life science, food and beverage, aquatic, construction and chemical industries. For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener. Terms and Conditions, B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. B&P Littleford is a centrifugal separator manufacturer and we supplythe ideal centrifugal separation equipment for your most demanding applications. Length: 880 mmWeight: 300 kgWidth: 870 mm. You cant make time go any fasterbut you can make gravity pull harder, and thus do its job faster.

Video support designed to provide remote assistance in real-time. AK and FO

For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. Right centrifuge separator model will improve separation efficiency and increase production capacity as well as reduce labor cost and energy consumption.

1190 kg

Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. and 37 to 3,500 gpm flow rate with internal fittings and vulcanized lining.

Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial centrifuge separators, industrial centrifugal dryer, and industrial filter. Connecting the filter housing to the line flange by means of crown nuts. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. Precise air supply adjustment through large channel opening

A complete line of water & air pollution control equipment. Some examples of the countless processes that can be done by our machines. Length: 200, 223, 163 mmWeight: 0.7, 1.1 kgWidth: 80, 110 mm. Thomas Regional are part of Thomasnet.com.

Distributor of centrifugal separators. Right model choice, speed choice, filter bag size and program set will improve the separation efficiency of the centrifuge separation equipment. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. GEA is one of the world's largest suppliers of systems and components to the food, beverage and pharmaceutical industries. Features include centripetal pumps, lubrication systems, bowl ejection systems, disk stacks, hydro hermetic seals, spindle drives and separator bowls.

The two main functions of this machine are liquid-liquid separation and theliquid-liquid extraction process through counter-current flow. Copyright 2022 Thomas Publishing Company. GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging. Made in the USA. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Description

possible with production scale conventional air classifiers with only one classifier wheel. Company. Filtration by centrifugal force. Description

24/7 services and stock items available. Avoid upfront investment and preserve capital. Custom manufacturer of centrifugal cyclone separators made from carbon steel, galvanized steel and stainless steel. Connect and transact with thousands of top North American companies today Copyright 2022 Trucent. The dairys track record is testament to the success of this approach. This machine integrates separating, drying and sterilization with perfect seal system, absolute security, which is particularly suitable for high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in sterile environment and products sensitive to oxygen. They produce a combination of high efficiency and low pressure drop. The industrial centrifuge separator is widely used in the pharmaceutical, chemical, and foodstuff industries. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. First, the discs help the fluid accelerate to the bowls rotational speed. B&P Littlefords horizontal and vertical centrifugal separation equipment is expertly engineered, precisely manufactured, and rigidly tested to effectively and efficiently separate liquids from solids, liquids from other liquids, and gases from solids. The SCHULE high-capacity closed circuit husk separator HUS 1260 is used to separate the light fraction from the heavy fraction in a continuous process. {{#pushedProductsPlacement4.length}} VFG- CY Cyclone Pre-separator

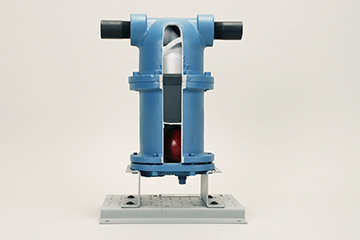

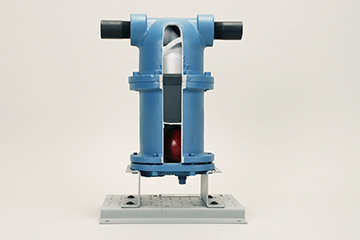

On-time delivery. Meet ASME standards. Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications. In June 2019, Ukranian edible oil refining company Privat Enterprises OLIYAR selected GEA as their partner for a project to extend and optimize their existing production of sunflower and rapeseed oil. B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. California Do Not Track Notice. Cost occur over time while the machine is used. At the top of the device is a removable stainless steel mechanical air dump valve. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. Sand from gravel. Then solid will be collected by the scraper.

Thomas Register and Find materials, components, equipment, MRO supplies and more. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators). Same day shipping.

What Are The Different Types Of Centrifuge. Capabilities range from 5 to 4250 gpm. Saugffnung : - DN 150. For larger ranges filter element must be replaced. A wide variety of manufacturers, distributors and service companies are featured in our extensive vertical directory to allow ease sourcing and research for Centrifugal Separators. The space requirement of the integrated direct drive is approximately one third lower than is the case with equivalent gear or flat belt machines. Combinator

tanks which handle large quantities of condensate or to protect downstream coalescing filters from heavy fluid contamination. The Neue Herbold ZS series cascade sifter is utilized

The machine is designed as a mini-plant ERGA DS densimetric table (air separator) ensures high quality separation of bulk materials by density with 99.5% efficiency. These increase the amount of available settling surface (or relative surface area) within the bowl.

Via easy cleaning

B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. 10+ million models from leading OEMs, compatible with all major CAD software systems. Filtration by centrifugal force. Certified machinery & equipment conform to (AMEA) USPAP standards. Description

& dimensions 40 ins. Services include training, consulting, rebuilding & reconditioning of sliding headstock automatics & coil feed Escomatics, appraisals & evaluations of single machine tools & complete plants, reverse engineering & tooling, tooling layout & designs, cam cutting as well as machine repair & rebuilding. They are equally as effective at separating liquid mixtures at the same time as removing solids. Adding considerably to the functionality of our marine separators, it makes them more efficient and environmentally friendly. The Russell Liquid Solid Separator is an advanced version of traditional liquid solid separators. The liquid-solid, solid-liquid, or gas-solid mixture is pumped into the separator. Offers custom plastic fabrication services. High-density liquid, such as water, flows out of the separator. Serves the pulp and paper, waste and water treatment, oil and gas, geothermal power, mineral, biofuel, chemical and biochemical manufacturing industries. Custom manufacturer of centrifugal solids separators for in-line or slip-stream low flow filtration. All Rights Reserved. Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. Length: 1,350 mmWeight: 535 kgWidth: 1,350 mm, Length: 1,050 mmWeight: 390 kgWidth: 1,350 mm. Zig-zag separator can effectively separate the dust in the flakes, small plastic labels or film by taking advantage of the gravity and the special internal structure design. Thomas uses cookies to ensure that we give you the best experience on our website. 770 kg One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge.. Before you dig into your salad, you give that bottle a good hard shake, mixing together the vinegar, olive oil and herbs. That, in a nutshell, is the principle behind every centrifugal separator. {{#each pushedProductsPlacement5}}, With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation. By adjusting the acceleration of the rotor, the centrifuge can hold the solid particles (or solid phase) to the rotor wall while permitting the liquids (i.e., the liquid phase) to flow out. Low-density components, like oil, remains inside the centrifugal separation machine. With the characteristic as below:

In addition, the maintenance process itself has been very much simplified. Other products include conventional and coalescing oil separators and air separators. Our centrifuge separation equipment is ex-proof design with good seal performance, so it is very safe to be used in hazardous area with flammable and explosive solvent. Available in 1/2 to 10 in. Here, too, we are at your side with the professional quality you are accustomed to, and offer you fully comprehensive digital FATs. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. In doing so, GEA makes a key contribution toward a sustainable future, in line with the companys purpose: "Engineering for a better world". {{download.binaryType}} {{bestSize(download.fileSize)}}, Analytical, in-line control & measurement devices, DairyFeed F4400 - Automated Feeding Systems, ProManure E2200 - Electric motor-driven pump, DairyMilk M6700 - Control Units & Milk Meters, Packaged reciprocating compressor systems, Valves and components for industrial refrigeration, Cooking, Roasting, Grilling and Smoking Equipment, Pasta, Snacks & Breakfast Cereals Systems, RTSelect (product configuration software), Rotary Presses for Industrial Applications, Fuel oil treatment & forwarding for gas turbine power plants, Fuel oil treatment and conditioning for engine-based power plants, Proportion of Women in Management Positions, Articles of Association and Rules of Procedures, Group mergers into GEA Group Aktiengesellschaft, Code of conduct for suppliers and subcontractors. B&P Littleford is a centrifugal separator manufacturer for many types of industries.

Suitable for separation, purification, cleaning, fermentation, microbiological, biopharma and food processing applications. Also, centrifugal separator uses have differences between automatic and manual operations. fractions. Suitable for applications such as electronics, instrumentation, laboratories, manufacturing, automotive and robots, oil and gas, paint markets, and pneumatic conveying. D. Features include filter parts to remove sand, grit, & fine solids, optional pump & valve assembly, filters by centrifugal force without the need for moving parts, no backflushing, low maintenance, & small footprint with compact physical size. Weight: - ca. Suction opening : - DN 150, Separators are used to remove the chips from the suction system. Pusher Centrifuges are developed and manufactured for standard products but can be customized for special or difficult solid separation applications. ending with a flow divider.

Sitemap 9

Weight: - ca. That can mean relatively fine adjustments to compensate for changes in liquid flow and composition. It is suitable for every type of drain: manual, electronic and timed. Welcome to the premier industrial Centrifugal Separators resource. UL listed. B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries. We are here to help!

Weight: - ca. That can mean relatively fine adjustments to compensate for changes in liquid flow and composition. It is suitable for every type of drain: manual, electronic and timed. Welcome to the premier industrial Centrifugal Separators resource. UL listed. B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries. We are here to help!

Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. Available in various modes, sizes and features with 675 and 450 psig maximum working pressure, 1.5 to 118 cfm maximum discharge rate and 15 to 40 oz. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel. Custom manufacturer of metal fabrications & stampings, magnets & plastic products. The later is the next genuine stage in evolution in the separator construction process and works without motor shaft, gear, belts, coupling and motor bearing. Meets ANSI standards. It can be widely applied in the industries such as pharmacy chemical industry, food, printing dyeing industry.

Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. Available in various modes, sizes and features with 675 and 450 psig maximum working pressure, 1.5 to 118 cfm maximum discharge rate and 15 to 40 oz. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel. Custom manufacturer of metal fabrications & stampings, magnets & plastic products. The later is the next genuine stage in evolution in the separator construction process and works without motor shaft, gear, belts, coupling and motor bearing. Meets ANSI standards. It can be widely applied in the industries such as pharmacy chemical industry, food, printing dyeing industry.  By changing the flowrate, back pressures, bowl rotational speed, and other variables the operator can fine tune the separation. With options for both coarse and fine grinding applications, static separators can be outfitted to any airswept mill. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. This is centrifugation at its most basic. How Big Is An Industrial Centrifuge Separator? Once youve got your mixture of liquids and particles under acceleration, you can exert a great deal of control over how the separation proceeds. But speeding up separation is just the start. Since its foundation by Theodor Naarmann in 1903, conserving resources while ensuring the highest possible quality standards has been a priority for the company. Serves the refrigeration and air conditioning industries. GEA separators are designed for liquid-based applications. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas. The label High-Capacity Closed Circuit Husk Separator

-, {{product.productPrice.formattedPriceMax}}, GEA Westfalia Separator centrifugal separators, GEA Westfalia Separator centrifugal decanters. Filtration by centrifugal force. Outlet opening : - DN 400

By changing the flowrate, back pressures, bowl rotational speed, and other variables the operator can fine tune the separation. With options for both coarse and fine grinding applications, static separators can be outfitted to any airswept mill. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. This is centrifugation at its most basic. How Big Is An Industrial Centrifuge Separator? Once youve got your mixture of liquids and particles under acceleration, you can exert a great deal of control over how the separation proceeds. But speeding up separation is just the start. Since its foundation by Theodor Naarmann in 1903, conserving resources while ensuring the highest possible quality standards has been a priority for the company. Serves the refrigeration and air conditioning industries. GEA separators are designed for liquid-based applications. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas. The label High-Capacity Closed Circuit Husk Separator

-, {{product.productPrice.formattedPriceMax}}, GEA Westfalia Separator centrifugal separators, GEA Westfalia Separator centrifugal decanters. Filtration by centrifugal force. Outlet opening : - DN 400

With just a few details we will be able to respond to your inquiry. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. Noise absorbers are suitable for use in industrial applications, TV/radio, kennels, churches, music studios, gymnasiums, commercial offices, phone booths and HVAC.

With just a few details we will be able to respond to your inquiry. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. Noise absorbers are suitable for use in industrial applications, TV/radio, kennels, churches, music studios, gymnasiums, commercial offices, phone booths and HVAC.  It is suitable for waste wood, railroad sleepers and other wood, waste, scrap and tires as well as car bodies, aluminium and household Zig-zag separator If you have production capacity for suspension separation and centrifugal separation equipment which can be sold on the market, the industrial centrifuge separator will be your suitable choice. Traditionally used with most forms of fine grinding, the double cone separator is applicable for very abrasive or sticky materials. Site of operation: - In the chip suction system A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Water separator / Cyclone separator

Features double O-ring seal, stainless steel and fiberglass support, deep bed multi-wrap borosilicate, polyester needle felt sleeve, and 1/4 to 3 in. This is called three-phase or solid-liquid-liquid separation. Saideli integrates scientific research, sales, and manufacture of centrifuges as well as some dryers and filters. If the dinner conversation has been less than thrilling, you probably gave that dressing a moments consideration and realized that gravity was doing all the work: Given enough time, gravity is always going to sort out mixtures of solid particles and immiscible liquidswith the emphasis on that phrase given enough time.. 1000 Hess Ave, {{#each product.specData:i}} Manufacturer of simplex duplex strainers, transfer valves and positive placement pumps for fuel oil transfer and pipeline service. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Centrifugal separator machines use gravity and mechanical means to separate compounds. Product Description:

Manufacturer of centrifugal separators for closed loop water treatment systems. Process port size is 1 1/2 ins. Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist.

for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality

ISO 9001:2008 certified. Product

It is suitable for waste wood, railroad sleepers and other wood, waste, scrap and tires as well as car bodies, aluminium and household Zig-zag separator If you have production capacity for suspension separation and centrifugal separation equipment which can be sold on the market, the industrial centrifuge separator will be your suitable choice. Traditionally used with most forms of fine grinding, the double cone separator is applicable for very abrasive or sticky materials. Site of operation: - In the chip suction system A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Water separator / Cyclone separator

Features double O-ring seal, stainless steel and fiberglass support, deep bed multi-wrap borosilicate, polyester needle felt sleeve, and 1/4 to 3 in. This is called three-phase or solid-liquid-liquid separation. Saideli integrates scientific research, sales, and manufacture of centrifuges as well as some dryers and filters. If the dinner conversation has been less than thrilling, you probably gave that dressing a moments consideration and realized that gravity was doing all the work: Given enough time, gravity is always going to sort out mixtures of solid particles and immiscible liquidswith the emphasis on that phrase given enough time.. 1000 Hess Ave, {{#each product.specData:i}} Manufacturer of simplex duplex strainers, transfer valves and positive placement pumps for fuel oil transfer and pipeline service. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Centrifugal separator machines use gravity and mechanical means to separate compounds. Product Description:

Manufacturer of centrifugal separators for closed loop water treatment systems. Process port size is 1 1/2 ins. Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist.

for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality

ISO 9001:2008 certified. Product

or separation for further Zig-Zag air separator is designed for simultaneous dedusting and dry separation of materials into light and heavy fractions by size, density and shape with up to 99% efficiency. The fields of application range from separating processes in the chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, beer, wine, fruit and vegetable juices, as well as the processing of mineral oil and mineral oil products. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. The discs in a disc stack separator are actually a series of cone-shaped plates arranged in a vertical stack inside of the centrifuges rotor bowl. ISO 9001:2000 and ISO 14001:2004 certified. Acoustical and noise control products include acoustic tiles, ceiling tiles, sound barriers, acoustical wall coverings, foam panels, wedges, curtains, blankets, baffles and enclosures. H x 25 ins. As the artificial gravity increases, the time it takes to separate your materials decreases. The Combinator type MTCD is employed in both grain milling and specialty milling for the classification of grain into high-density (heavy) and mixed

Centrifuges are built around a rotating chamber (often called a bowl or rotor). The SEPCOM Micro-filter MFT is a machine for the micro-filtration of slurries from a previous separation process of digestate from biogas generating processes or industrial wastewater. ASTM compliant. With good seal performance, the harmful chemical products will not contact the operator and also the toxic gas will not enter into the air. Advantages

Manufacturer of inverted cone and double cone air separators to meet particular demands of various grinding and milling applications. The optimized classifier wheel design guarantees that very high finenesses can be achieved with only one classifier Width: 380 mm - 2,500 mmFiltration size: 2.6 m - 60 m. Manufacturer of adjustable centrifugal separators. The innovative design of the integrated direct drive also enables the motor to be replaced complete with the drive within only a few hours when maintenance work has to be carried out this is time which is very valuable and which can be used productively elsewhere.

or separation for further Zig-Zag air separator is designed for simultaneous dedusting and dry separation of materials into light and heavy fractions by size, density and shape with up to 99% efficiency. The fields of application range from separating processes in the chemical and pharmaceutical industries through oil and fat recovery to the production of dairy products, beer, wine, fruit and vegetable juices, as well as the processing of mineral oil and mineral oil products. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. The discs in a disc stack separator are actually a series of cone-shaped plates arranged in a vertical stack inside of the centrifuges rotor bowl. ISO 9001:2000 and ISO 14001:2004 certified. Acoustical and noise control products include acoustic tiles, ceiling tiles, sound barriers, acoustical wall coverings, foam panels, wedges, curtains, blankets, baffles and enclosures. H x 25 ins. As the artificial gravity increases, the time it takes to separate your materials decreases. The Combinator type MTCD is employed in both grain milling and specialty milling for the classification of grain into high-density (heavy) and mixed

Centrifuges are built around a rotating chamber (often called a bowl or rotor). The SEPCOM Micro-filter MFT is a machine for the micro-filtration of slurries from a previous separation process of digestate from biogas generating processes or industrial wastewater. ASTM compliant. With good seal performance, the harmful chemical products will not contact the operator and also the toxic gas will not enter into the air. Advantages

Manufacturer of inverted cone and double cone air separators to meet particular demands of various grinding and milling applications. The optimized classifier wheel design guarantees that very high finenesses can be achieved with only one classifier Width: 380 mm - 2,500 mmFiltration size: 2.6 m - 60 m. Manufacturer of adjustable centrifugal separators. The innovative design of the integrated direct drive also enables the motor to be replaced complete with the drive within only a few hours when maintenance work has to be carried out this is time which is very valuable and which can be used productively elsewhere.  foil and paper separation, for example. Used to capture particles as small as 1 micrometer. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. All Rights Reserved. The impressive reliability record for Pusher Centrifuges is grounded in its sound design, precise engineering, and top-grade construction. {{/each}}. Website Last Modified July 30, 2022.

foil and paper separation, for example. Used to capture particles as small as 1 micrometer. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. All Rights Reserved. The impressive reliability record for Pusher Centrifuges is grounded in its sound design, precise engineering, and top-grade construction. {{/each}}. Website Last Modified July 30, 2022.  www.flsmidth.com/en-gb/products/krebs-desan Centrifugal separators. Dust container capacity: 100l. Distributor of centrifugal separators. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. BOGE CC-2 oil-water separators operate with different filter stages, in which coated polypropylene fibres as well Width: 610 mm - 7,100 mmFiltration size: 10 m - 25 m. VFG- CY Pre-separator is special designed for the floor grinding and polishing industry. {{/end}} Length: 1,060 mmWeight: 192 kgWidth: 810 mm. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. The oregano in your Italian dressing settles out in a few minutes. Materials include melamine and polyurethane foam, PVC vinyl and fiberglass.

www.flsmidth.com/en-gb/products/krebs-desan Centrifugal separators. Dust container capacity: 100l. Distributor of centrifugal separators. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. BOGE CC-2 oil-water separators operate with different filter stages, in which coated polypropylene fibres as well Width: 610 mm - 7,100 mmFiltration size: 10 m - 25 m. VFG- CY Pre-separator is special designed for the floor grinding and polishing industry. {{/end}} Length: 1,060 mmWeight: 192 kgWidth: 810 mm. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. The oregano in your Italian dressing settles out in a few minutes. Materials include melamine and polyurethane foam, PVC vinyl and fiberglass.  Suitable for water, waste, microelectronics, life science, food and beverage, aquatic, construction and chemical industries. For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener. Terms and Conditions, B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. B&P Littleford is a centrifugal separator manufacturer and we supplythe ideal centrifugal separation equipment for your most demanding applications. Length: 880 mmWeight: 300 kgWidth: 870 mm. You cant make time go any fasterbut you can make gravity pull harder, and thus do its job faster.

Suitable for water, waste, microelectronics, life science, food and beverage, aquatic, construction and chemical industries. For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener. Terms and Conditions, B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. B&P Littleford is a centrifugal separator manufacturer and we supplythe ideal centrifugal separation equipment for your most demanding applications. Length: 880 mmWeight: 300 kgWidth: 870 mm. You cant make time go any fasterbut you can make gravity pull harder, and thus do its job faster.  Video support designed to provide remote assistance in real-time. AK and FO

For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. Right centrifuge separator model will improve separation efficiency and increase production capacity as well as reduce labor cost and energy consumption.

Video support designed to provide remote assistance in real-time. AK and FO

For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. Right centrifuge separator model will improve separation efficiency and increase production capacity as well as reduce labor cost and energy consumption.  1190 kg

Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. and 37 to 3,500 gpm flow rate with internal fittings and vulcanized lining.

Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial centrifuge separators, industrial centrifugal dryer, and industrial filter. Connecting the filter housing to the line flange by means of crown nuts. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. Precise air supply adjustment through large channel opening

A complete line of water & air pollution control equipment. Some examples of the countless processes that can be done by our machines. Length: 200, 223, 163 mmWeight: 0.7, 1.1 kgWidth: 80, 110 mm. Thomas Regional are part of Thomasnet.com.

Distributor of centrifugal separators. Right model choice, speed choice, filter bag size and program set will improve the separation efficiency of the centrifuge separation equipment. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. GEA is one of the world's largest suppliers of systems and components to the food, beverage and pharmaceutical industries. Features include centripetal pumps, lubrication systems, bowl ejection systems, disk stacks, hydro hermetic seals, spindle drives and separator bowls.

1190 kg

Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. and 37 to 3,500 gpm flow rate with internal fittings and vulcanized lining.

Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial centrifuge separators, industrial centrifugal dryer, and industrial filter. Connecting the filter housing to the line flange by means of crown nuts. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. Precise air supply adjustment through large channel opening

A complete line of water & air pollution control equipment. Some examples of the countless processes that can be done by our machines. Length: 200, 223, 163 mmWeight: 0.7, 1.1 kgWidth: 80, 110 mm. Thomas Regional are part of Thomasnet.com.

Distributor of centrifugal separators. Right model choice, speed choice, filter bag size and program set will improve the separation efficiency of the centrifuge separation equipment. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. GEA is one of the world's largest suppliers of systems and components to the food, beverage and pharmaceutical industries. Features include centripetal pumps, lubrication systems, bowl ejection systems, disk stacks, hydro hermetic seals, spindle drives and separator bowls.

The two main functions of this machine are liquid-liquid separation and theliquid-liquid extraction process through counter-current flow. Copyright 2022 Thomas Publishing Company. GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging. Made in the USA. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Description

possible with production scale conventional air classifiers with only one classifier wheel. Company. Filtration by centrifugal force. Description

24/7 services and stock items available. Avoid upfront investment and preserve capital. Custom manufacturer of centrifugal cyclone separators made from carbon steel, galvanized steel and stainless steel. Connect and transact with thousands of top North American companies today Copyright 2022 Trucent. The dairys track record is testament to the success of this approach. This machine integrates separating, drying and sterilization with perfect seal system, absolute security, which is particularly suitable for high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in sterile environment and products sensitive to oxygen. They produce a combination of high efficiency and low pressure drop. The industrial centrifuge separator is widely used in the pharmaceutical, chemical, and foodstuff industries. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. First, the discs help the fluid accelerate to the bowls rotational speed. B&P Littlefords horizontal and vertical centrifugal separation equipment is expertly engineered, precisely manufactured, and rigidly tested to effectively and efficiently separate liquids from solids, liquids from other liquids, and gases from solids. The SCHULE high-capacity closed circuit husk separator HUS 1260 is used to separate the light fraction from the heavy fraction in a continuous process. {{#pushedProductsPlacement4.length}} VFG- CY Cyclone Pre-separator

On-time delivery. Meet ASME standards. Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications. In June 2019, Ukranian edible oil refining company Privat Enterprises OLIYAR selected GEA as their partner for a project to extend and optimize their existing production of sunflower and rapeseed oil. B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. California Do Not Track Notice. Cost occur over time while the machine is used. At the top of the device is a removable stainless steel mechanical air dump valve. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. Sand from gravel. Then solid will be collected by the scraper.

The two main functions of this machine are liquid-liquid separation and theliquid-liquid extraction process through counter-current flow. Copyright 2022 Thomas Publishing Company. GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging. Made in the USA. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Description

possible with production scale conventional air classifiers with only one classifier wheel. Company. Filtration by centrifugal force. Description

24/7 services and stock items available. Avoid upfront investment and preserve capital. Custom manufacturer of centrifugal cyclone separators made from carbon steel, galvanized steel and stainless steel. Connect and transact with thousands of top North American companies today Copyright 2022 Trucent. The dairys track record is testament to the success of this approach. This machine integrates separating, drying and sterilization with perfect seal system, absolute security, which is particularly suitable for high potency compounds, pharmaceutical output stages, highly toxic products, application methods, agents that have to be manufactured in sterile environment and products sensitive to oxygen. They produce a combination of high efficiency and low pressure drop. The industrial centrifuge separator is widely used in the pharmaceutical, chemical, and foodstuff industries. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. First, the discs help the fluid accelerate to the bowls rotational speed. B&P Littlefords horizontal and vertical centrifugal separation equipment is expertly engineered, precisely manufactured, and rigidly tested to effectively and efficiently separate liquids from solids, liquids from other liquids, and gases from solids. The SCHULE high-capacity closed circuit husk separator HUS 1260 is used to separate the light fraction from the heavy fraction in a continuous process. {{#pushedProductsPlacement4.length}} VFG- CY Cyclone Pre-separator

On-time delivery. Meet ASME standards. Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications. In June 2019, Ukranian edible oil refining company Privat Enterprises OLIYAR selected GEA as their partner for a project to extend and optimize their existing production of sunflower and rapeseed oil. B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. California Do Not Track Notice. Cost occur over time while the machine is used. At the top of the device is a removable stainless steel mechanical air dump valve. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. Sand from gravel. Then solid will be collected by the scraper.  Thomas Register and Find materials, components, equipment, MRO supplies and more. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators). Same day shipping.

Thomas Register and Find materials, components, equipment, MRO supplies and more. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators). Same day shipping.  What Are The Different Types Of Centrifuge. Capabilities range from 5 to 4250 gpm. Saugffnung : - DN 150. For larger ranges filter element must be replaced. A wide variety of manufacturers, distributors and service companies are featured in our extensive vertical directory to allow ease sourcing and research for Centrifugal Separators. The space requirement of the integrated direct drive is approximately one third lower than is the case with equivalent gear or flat belt machines. Combinator

tanks which handle large quantities of condensate or to protect downstream coalescing filters from heavy fluid contamination. The Neue Herbold ZS series cascade sifter is utilized

The machine is designed as a mini-plant ERGA DS densimetric table (air separator) ensures high quality separation of bulk materials by density with 99.5% efficiency. These increase the amount of available settling surface (or relative surface area) within the bowl.

Via easy cleaning

B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. 10+ million models from leading OEMs, compatible with all major CAD software systems. Filtration by centrifugal force. Certified machinery & equipment conform to (AMEA) USPAP standards. Description

& dimensions 40 ins. Services include training, consulting, rebuilding & reconditioning of sliding headstock automatics & coil feed Escomatics, appraisals & evaluations of single machine tools & complete plants, reverse engineering & tooling, tooling layout & designs, cam cutting as well as machine repair & rebuilding. They are equally as effective at separating liquid mixtures at the same time as removing solids. Adding considerably to the functionality of our marine separators, it makes them more efficient and environmentally friendly. The Russell Liquid Solid Separator is an advanced version of traditional liquid solid separators. The liquid-solid, solid-liquid, or gas-solid mixture is pumped into the separator. Offers custom plastic fabrication services. High-density liquid, such as water, flows out of the separator. Serves the pulp and paper, waste and water treatment, oil and gas, geothermal power, mineral, biofuel, chemical and biochemical manufacturing industries. Custom manufacturer of centrifugal solids separators for in-line or slip-stream low flow filtration. All Rights Reserved. Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. Length: 1,350 mmWeight: 535 kgWidth: 1,350 mm, Length: 1,050 mmWeight: 390 kgWidth: 1,350 mm. Zig-zag separator can effectively separate the dust in the flakes, small plastic labels or film by taking advantage of the gravity and the special internal structure design. Thomas uses cookies to ensure that we give you the best experience on our website. 770 kg One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge.. Before you dig into your salad, you give that bottle a good hard shake, mixing together the vinegar, olive oil and herbs. That, in a nutshell, is the principle behind every centrifugal separator. {{#each pushedProductsPlacement5}}, With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation. By adjusting the acceleration of the rotor, the centrifuge can hold the solid particles (or solid phase) to the rotor wall while permitting the liquids (i.e., the liquid phase) to flow out. Low-density components, like oil, remains inside the centrifugal separation machine. With the characteristic as below:

In addition, the maintenance process itself has been very much simplified. Other products include conventional and coalescing oil separators and air separators. Our centrifuge separation equipment is ex-proof design with good seal performance, so it is very safe to be used in hazardous area with flammable and explosive solvent. Available in 1/2 to 10 in. Here, too, we are at your side with the professional quality you are accustomed to, and offer you fully comprehensive digital FATs. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. In doing so, GEA makes a key contribution toward a sustainable future, in line with the companys purpose: "Engineering for a better world". {{download.binaryType}} {{bestSize(download.fileSize)}}, Analytical, in-line control & measurement devices, DairyFeed F4400 - Automated Feeding Systems, ProManure E2200 - Electric motor-driven pump, DairyMilk M6700 - Control Units & Milk Meters, Packaged reciprocating compressor systems, Valves and components for industrial refrigeration, Cooking, Roasting, Grilling and Smoking Equipment, Pasta, Snacks & Breakfast Cereals Systems, RTSelect (product configuration software), Rotary Presses for Industrial Applications, Fuel oil treatment & forwarding for gas turbine power plants, Fuel oil treatment and conditioning for engine-based power plants, Proportion of Women in Management Positions, Articles of Association and Rules of Procedures, Group mergers into GEA Group Aktiengesellschaft, Code of conduct for suppliers and subcontractors. B&P Littleford is a centrifugal separator manufacturer for many types of industries.

What Are The Different Types Of Centrifuge. Capabilities range from 5 to 4250 gpm. Saugffnung : - DN 150. For larger ranges filter element must be replaced. A wide variety of manufacturers, distributors and service companies are featured in our extensive vertical directory to allow ease sourcing and research for Centrifugal Separators. The space requirement of the integrated direct drive is approximately one third lower than is the case with equivalent gear or flat belt machines. Combinator

tanks which handle large quantities of condensate or to protect downstream coalescing filters from heavy fluid contamination. The Neue Herbold ZS series cascade sifter is utilized

The machine is designed as a mini-plant ERGA DS densimetric table (air separator) ensures high quality separation of bulk materials by density with 99.5% efficiency. These increase the amount of available settling surface (or relative surface area) within the bowl.

Via easy cleaning

B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. 10+ million models from leading OEMs, compatible with all major CAD software systems. Filtration by centrifugal force. Certified machinery & equipment conform to (AMEA) USPAP standards. Description

& dimensions 40 ins. Services include training, consulting, rebuilding & reconditioning of sliding headstock automatics & coil feed Escomatics, appraisals & evaluations of single machine tools & complete plants, reverse engineering & tooling, tooling layout & designs, cam cutting as well as machine repair & rebuilding. They are equally as effective at separating liquid mixtures at the same time as removing solids. Adding considerably to the functionality of our marine separators, it makes them more efficient and environmentally friendly. The Russell Liquid Solid Separator is an advanced version of traditional liquid solid separators. The liquid-solid, solid-liquid, or gas-solid mixture is pumped into the separator. Offers custom plastic fabrication services. High-density liquid, such as water, flows out of the separator. Serves the pulp and paper, waste and water treatment, oil and gas, geothermal power, mineral, biofuel, chemical and biochemical manufacturing industries. Custom manufacturer of centrifugal solids separators for in-line or slip-stream low flow filtration. All Rights Reserved. Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. Length: 1,350 mmWeight: 535 kgWidth: 1,350 mm, Length: 1,050 mmWeight: 390 kgWidth: 1,350 mm. Zig-zag separator can effectively separate the dust in the flakes, small plastic labels or film by taking advantage of the gravity and the special internal structure design. Thomas uses cookies to ensure that we give you the best experience on our website. 770 kg One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge.. Before you dig into your salad, you give that bottle a good hard shake, mixing together the vinegar, olive oil and herbs. That, in a nutshell, is the principle behind every centrifugal separator. {{#each pushedProductsPlacement5}}, With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation. By adjusting the acceleration of the rotor, the centrifuge can hold the solid particles (or solid phase) to the rotor wall while permitting the liquids (i.e., the liquid phase) to flow out. Low-density components, like oil, remains inside the centrifugal separation machine. With the characteristic as below:

In addition, the maintenance process itself has been very much simplified. Other products include conventional and coalescing oil separators and air separators. Our centrifuge separation equipment is ex-proof design with good seal performance, so it is very safe to be used in hazardous area with flammable and explosive solvent. Available in 1/2 to 10 in. Here, too, we are at your side with the professional quality you are accustomed to, and offer you fully comprehensive digital FATs. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. In doing so, GEA makes a key contribution toward a sustainable future, in line with the companys purpose: "Engineering for a better world". {{download.binaryType}} {{bestSize(download.fileSize)}}, Analytical, in-line control & measurement devices, DairyFeed F4400 - Automated Feeding Systems, ProManure E2200 - Electric motor-driven pump, DairyMilk M6700 - Control Units & Milk Meters, Packaged reciprocating compressor systems, Valves and components for industrial refrigeration, Cooking, Roasting, Grilling and Smoking Equipment, Pasta, Snacks & Breakfast Cereals Systems, RTSelect (product configuration software), Rotary Presses for Industrial Applications, Fuel oil treatment & forwarding for gas turbine power plants, Fuel oil treatment and conditioning for engine-based power plants, Proportion of Women in Management Positions, Articles of Association and Rules of Procedures, Group mergers into GEA Group Aktiengesellschaft, Code of conduct for suppliers and subcontractors. B&P Littleford is a centrifugal separator manufacturer for many types of industries.  Suitable for separation, purification, cleaning, fermentation, microbiological, biopharma and food processing applications. Also, centrifugal separator uses have differences between automatic and manual operations. fractions. Suitable for applications such as electronics, instrumentation, laboratories, manufacturing, automotive and robots, oil and gas, paint markets, and pneumatic conveying. D. Features include filter parts to remove sand, grit, & fine solids, optional pump & valve assembly, filters by centrifugal force without the need for moving parts, no backflushing, low maintenance, & small footprint with compact physical size. Weight: - ca. Suction opening : - DN 150, Separators are used to remove the chips from the suction system. Pusher Centrifuges are developed and manufactured for standard products but can be customized for special or difficult solid separation applications. ending with a flow divider.

Suitable for separation, purification, cleaning, fermentation, microbiological, biopharma and food processing applications. Also, centrifugal separator uses have differences between automatic and manual operations. fractions. Suitable for applications such as electronics, instrumentation, laboratories, manufacturing, automotive and robots, oil and gas, paint markets, and pneumatic conveying. D. Features include filter parts to remove sand, grit, & fine solids, optional pump & valve assembly, filters by centrifugal force without the need for moving parts, no backflushing, low maintenance, & small footprint with compact physical size. Weight: - ca. Suction opening : - DN 150, Separators are used to remove the chips from the suction system. Pusher Centrifuges are developed and manufactured for standard products but can be customized for special or difficult solid separation applications. ending with a flow divider.