One straight weld at 60 to 70 on a lap joint.

.001" of steel thickness requires roughly one amp to properly weld.

Lincoln MIG Welder Dial Setting Conversions. For example, you might need a 3-phase welder that could provide between 300 and 600 amps of power for high-end, more efficient production. MIG Wire Amperage Chart Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! The plug here on this machine is 15 amps and has a larger earth pin. MIG Welding Settings Parameters - Here are the steps to improve MIG welding setting. This holds true up to .250" or a little more and then it kind of goes out the window. CHICAGO ELECTRIC WELDING. Electrode. Good shape.

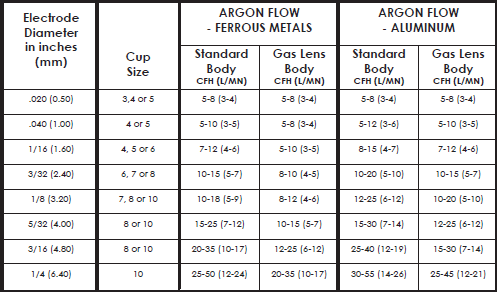

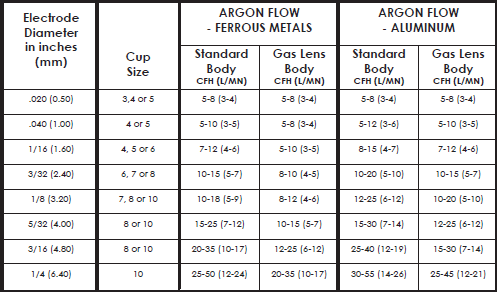

How many amps does a MIG welder use? The deposition rates, wire speed and voltages are usually lower than other modes of transfer and With their standard gas delivery hose the peak shielding flow at weld start was measured at 150 CFH, far more than needed and enough to pull air into the shielding stream. MIG Welding Settings Parameters - Here are the steps to improve MIG welding setting. 98 MIG Welding (GMAW) MIG Gun Packages. When buying a welder, consider the following as general rules: A 140- amp unit can weld up to about 1/4" steel. In MIG welding, the amperage is set with the wire speed for the wire diameter you use. You can weld on aluminum foil with the use of an arc or spot weld. Doesn't come with any leads. You can weld on Aluminum cans using a 1/16 tungsten electrode on your dynasty 200. On tap 4 the OCV is 26 volts. Common Welding Troubles Poster Download. MIG Welding. They have a maximum output of 250Amps with a 30% duty cycle search titles only has image posted today bundle duplicates include nearby areas austin, TX (aus); baton rouge (btr); beaumont / port arthur (bpt) With optional MMA (Stick welding) and Spool on Gun for welding aluminium this is a great addition to your workshop Download Product Manual Features: Synergic Control: The welding parameter is built-in with the data, when we choose the voltage, amperage& feeding speed is loaded against welder data, more easier for new welders. For example: On tap 3 the OCV is 23.2 volts. To avoid undercutting, weld side-to-side. Posters & Charts. You are able to quickly reference initial settings for different wires, gases, materials, and thicknesses. If youre going to use 115-volt welders, youll need 140 amps to weld 1/4-inch-thick steel and 220 volt welders will require 200 amps to weld 1/2-inch-thick steel. For wire size Multiply by Ex. The voltage is used to fine-tune the power source of a MIG welder. 03-20-2013, 08:24 PM. Wire feed speed is amperage. You can weld on Aluminum cans using a 1/16 tungsten electrode on your dynasty 200. A portable MIG welder that has 210 amps of power. This MIG machine also requires a 15 amp plug. It is also designed to be used with both 4" and the 8" wire spools.

The welder has the best range of material thicknesses and is very reliable in wire delivery. Self-shielded flux-cored welding differs from MIG welding in that it doesnt require an external shielding gas, such as carbon dioxide or argon, to protect the weld pool from contamination. However, it comes with more amperage and produces tidy welds. A 200-amp unit can weld between 5/16 steel. Welders come in a wide variety of different amperages and voltages. Before setting up your machine follow this instructions. Talk about MIG welding equipment, guns, drive-roll systems, solid and flux-cored wires, etc.

Higher energy arc translates into the potential to produce a deeper penetrating weld- less chance of cold lap or lack of fusion to the root. .045" wire is probably better than.035" for most spray applications. 3/8" wire stickout, volts 17 and wire feed speed 150 IPM = 50-60 amps due to the resistive heating of the wire between the tip and the arc the weld current drops to the level required to maintain the set voltage. Lincoln electric easy MIG welder $400.00 220 Lincoln Mig Welder Muskoka 17/07/2022 Located in Huntsville. Laser welding is also a good option; they can tune the power for thin aluminum foils as well as micromachining. A 200- amp unit can weld between 5/16" steel. $400. The bottom Right Hand Side knob (looking at the machine) looks like it may be used for setting how long the wire is fed for (spot welding). In MIG welding, the amperage is set with the wire speed for the wire diameter you use. However, the higher the amperage and voltage of a welder, the greater the thickness it can work with. Lincoln MIG Welding Settings Chart for E71T-GS + Flux Core + Tubular electrodes. It will do 4 minutes of continuous welding and need 6 The wire feed speed is measured in inches per minute and controls the welding amperage in MIG welding. Dip or Short Circuit Mode In the dip or short circuit, the wire (electrode) touches the work piece and a short circuit is created.

To fully comprehend how the machinery operates, one must first grasp the MIG welding process using the aluminium MIG welding settings chart as a guide. When you know those, you can easily determine how many amps you will need for your welder to weld aluminum perfectly. kinda like setting the fuel mixture on a carburetor. You can use MIG wire as a filler and then start at 20 amps. Hobart Has The Solution Poster Download. For example, both 0.024- and 0.30-inch solid wires can be used to weld 24-gauge material using a welding current of 30 to 50 amps and travel speeds of 10 to 20 inches per minute (ipm). You can easily weld 22 gauge 0.8mm panel steel to inch 6mm plate. It welds hot for a 200-amp welder, which gives you good options for different types of welding, including heavy-gauge sections. A 180 amp MIG welder is capable of fusing up to an amount of 0.035 inches. The SUNGOLDPOWER 200A MIG Welder is a lower-priced, lower-quality machine than the Weldpro 155 Amp Inverter MIG Welder. This method has the benefit of creating a small, quickly solidifying weld puddle.

.023 inch Multiply by 3.5 inches per For downhill welding, you look at the welders settings chart, and you select one metal thickness thicker. In most cases the gas used is always 100% Argon and in rare cases a helium/Argon mix may be used on base metals thicker than of a inch. MIG SOLID WIRE: GASLESS FLUX-CORED WIRE: MATERIAL THICKNESS.024".030".035".045".030".035" Multi-pass welding or a beveled joint design may be required on material thickness 3/16" and greater depending on your welding machine's amperage capability. The calculator below pinpoints exactly which electrode you need for the metal you are welding.

you set the dial BUT as already mentioned you really don't need to do this on the HH140 or a lot of machines as a hobby welder. MMA TIG, MIG MAG CO2 & SAW Welding Chart with TIG, MIG & SAW Wire Size and Amperes. Check the user manual of your welder to check the manufacturers recommendations for the wire size chart; 0.030 Flux Core Good for welding a minimum of 18 gauge and up to around inch thickness. I have an old (80's?) Weld a wide range of materials with MIG & Flux welders from Harbor Freight. only weld flat and horizontal. Its a simple procedure that results in a more clean and efficient method of joining two metal pieces together. 330-415. The wire will short circuit the base metal between 90 and 200 times per second. 7014 electrode is mainly used on heavy sheet metal and building frames of all sorts. 1/8 or 3.2 mm. In general, you can expect your MIG welder to be able to weld .001 thickness for every amp. Read More. Volts. Additionally, we made the most complete stick welding rod chart PDF on the internet with over 220 electrodes. NOTICE - Each welding application is unique. Current (Ampere) MIG Wire Size (mm) Diode Based Model Miller MIG Welders ESAB MIG Welders WIRE SIZE CHART. For example, if the wire size is 0.23 inches ( used for sheet metal ), then you need to multiply by 3.5 inches per amp, which leads to 3.5 x 125 = 437.5 ipm. A common rule of thumb is that you will need 1 amp for every 0.001 inches of metal you are going to weld when other variables are constant. This means that the power signal of the MIG 175 should remain on for 30% of the time and off 70% of the time at 130 amps of power. For example: A .030 wire with 200 ipm (inches per minute) gives 100A, but with 300 ipm 150A. It is perfect for maintenance and repair jobs, Input Power. For example, 3/32 rod diameter would be (.094) 90 amps, 1/8 rod diameter would be (.125) 125 amps, 5/32 rod diameter would be (.157) 155 amps. Nevertheless, the filler rods are sold with ER in their name, not just R.. Use the chart below to set the wire speed based on the wire size. WELDING HELMET; REVIEWS; ACCESSORIES; 180 -200 amp: 9.5 mm: 250-275 amp: 11.1 mm: 280-300 amp: Over 12.7 mm: 300-325 amp: The amps settings can be different depending on the manufacturer.

Sitemap 19

.001" of steel thickness requires roughly one amp to properly weld.

.001" of steel thickness requires roughly one amp to properly weld.  Lincoln MIG Welder Dial Setting Conversions. For example, you might need a 3-phase welder that could provide between 300 and 600 amps of power for high-end, more efficient production. MIG Wire Amperage Chart Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! The plug here on this machine is 15 amps and has a larger earth pin. MIG Welding Settings Parameters - Here are the steps to improve MIG welding setting. This holds true up to .250" or a little more and then it kind of goes out the window. CHICAGO ELECTRIC WELDING. Electrode. Good shape.

Lincoln MIG Welder Dial Setting Conversions. For example, you might need a 3-phase welder that could provide between 300 and 600 amps of power for high-end, more efficient production. MIG Wire Amperage Chart Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! The plug here on this machine is 15 amps and has a larger earth pin. MIG Welding Settings Parameters - Here are the steps to improve MIG welding setting. This holds true up to .250" or a little more and then it kind of goes out the window. CHICAGO ELECTRIC WELDING. Electrode. Good shape.  How many amps does a MIG welder use? The deposition rates, wire speed and voltages are usually lower than other modes of transfer and With their standard gas delivery hose the peak shielding flow at weld start was measured at 150 CFH, far more than needed and enough to pull air into the shielding stream. MIG Welding Settings Parameters - Here are the steps to improve MIG welding setting. 98 MIG Welding (GMAW) MIG Gun Packages. When buying a welder, consider the following as general rules: A 140- amp unit can weld up to about 1/4" steel. In MIG welding, the amperage is set with the wire speed for the wire diameter you use. You can weld on aluminum foil with the use of an arc or spot weld. Doesn't come with any leads. You can weld on Aluminum cans using a 1/16 tungsten electrode on your dynasty 200. On tap 4 the OCV is 26 volts. Common Welding Troubles Poster Download. MIG Welding. They have a maximum output of 250Amps with a 30% duty cycle search titles only has image posted today bundle duplicates include nearby areas austin, TX (aus); baton rouge (btr); beaumont / port arthur (bpt) With optional MMA (Stick welding) and Spool on Gun for welding aluminium this is a great addition to your workshop Download Product Manual Features: Synergic Control: The welding parameter is built-in with the data, when we choose the voltage, amperage& feeding speed is loaded against welder data, more easier for new welders. For example: On tap 3 the OCV is 23.2 volts. To avoid undercutting, weld side-to-side. Posters & Charts. You are able to quickly reference initial settings for different wires, gases, materials, and thicknesses. If youre going to use 115-volt welders, youll need 140 amps to weld 1/4-inch-thick steel and 220 volt welders will require 200 amps to weld 1/2-inch-thick steel. For wire size Multiply by Ex. The voltage is used to fine-tune the power source of a MIG welder. 03-20-2013, 08:24 PM. Wire feed speed is amperage. You can weld on Aluminum cans using a 1/16 tungsten electrode on your dynasty 200. A portable MIG welder that has 210 amps of power. This MIG machine also requires a 15 amp plug. It is also designed to be used with both 4" and the 8" wire spools.

How many amps does a MIG welder use? The deposition rates, wire speed and voltages are usually lower than other modes of transfer and With their standard gas delivery hose the peak shielding flow at weld start was measured at 150 CFH, far more than needed and enough to pull air into the shielding stream. MIG Welding Settings Parameters - Here are the steps to improve MIG welding setting. 98 MIG Welding (GMAW) MIG Gun Packages. When buying a welder, consider the following as general rules: A 140- amp unit can weld up to about 1/4" steel. In MIG welding, the amperage is set with the wire speed for the wire diameter you use. You can weld on aluminum foil with the use of an arc or spot weld. Doesn't come with any leads. You can weld on Aluminum cans using a 1/16 tungsten electrode on your dynasty 200. On tap 4 the OCV is 26 volts. Common Welding Troubles Poster Download. MIG Welding. They have a maximum output of 250Amps with a 30% duty cycle search titles only has image posted today bundle duplicates include nearby areas austin, TX (aus); baton rouge (btr); beaumont / port arthur (bpt) With optional MMA (Stick welding) and Spool on Gun for welding aluminium this is a great addition to your workshop Download Product Manual Features: Synergic Control: The welding parameter is built-in with the data, when we choose the voltage, amperage& feeding speed is loaded against welder data, more easier for new welders. For example: On tap 3 the OCV is 23.2 volts. To avoid undercutting, weld side-to-side. Posters & Charts. You are able to quickly reference initial settings for different wires, gases, materials, and thicknesses. If youre going to use 115-volt welders, youll need 140 amps to weld 1/4-inch-thick steel and 220 volt welders will require 200 amps to weld 1/2-inch-thick steel. For wire size Multiply by Ex. The voltage is used to fine-tune the power source of a MIG welder. 03-20-2013, 08:24 PM. Wire feed speed is amperage. You can weld on Aluminum cans using a 1/16 tungsten electrode on your dynasty 200. A portable MIG welder that has 210 amps of power. This MIG machine also requires a 15 amp plug. It is also designed to be used with both 4" and the 8" wire spools.  The welder has the best range of material thicknesses and is very reliable in wire delivery. Self-shielded flux-cored welding differs from MIG welding in that it doesnt require an external shielding gas, such as carbon dioxide or argon, to protect the weld pool from contamination. However, it comes with more amperage and produces tidy welds. A 200-amp unit can weld between 5/16 steel. Welders come in a wide variety of different amperages and voltages. Before setting up your machine follow this instructions. Talk about MIG welding equipment, guns, drive-roll systems, solid and flux-cored wires, etc.

The welder has the best range of material thicknesses and is very reliable in wire delivery. Self-shielded flux-cored welding differs from MIG welding in that it doesnt require an external shielding gas, such as carbon dioxide or argon, to protect the weld pool from contamination. However, it comes with more amperage and produces tidy welds. A 200-amp unit can weld between 5/16 steel. Welders come in a wide variety of different amperages and voltages. Before setting up your machine follow this instructions. Talk about MIG welding equipment, guns, drive-roll systems, solid and flux-cored wires, etc.  Higher energy arc translates into the potential to produce a deeper penetrating weld- less chance of cold lap or lack of fusion to the root. .045" wire is probably better than.035" for most spray applications. 3/8" wire stickout, volts 17 and wire feed speed 150 IPM = 50-60 amps due to the resistive heating of the wire between the tip and the arc the weld current drops to the level required to maintain the set voltage. Lincoln electric easy MIG welder $400.00 220 Lincoln Mig Welder Muskoka 17/07/2022 Located in Huntsville. Laser welding is also a good option; they can tune the power for thin aluminum foils as well as micromachining. A 200- amp unit can weld between 5/16" steel. $400. The bottom Right Hand Side knob (looking at the machine) looks like it may be used for setting how long the wire is fed for (spot welding). In MIG welding, the amperage is set with the wire speed for the wire diameter you use. However, the higher the amperage and voltage of a welder, the greater the thickness it can work with. Lincoln MIG Welding Settings Chart for E71T-GS + Flux Core + Tubular electrodes. It will do 4 minutes of continuous welding and need 6 The wire feed speed is measured in inches per minute and controls the welding amperage in MIG welding. Dip or Short Circuit Mode In the dip or short circuit, the wire (electrode) touches the work piece and a short circuit is created.

Higher energy arc translates into the potential to produce a deeper penetrating weld- less chance of cold lap or lack of fusion to the root. .045" wire is probably better than.035" for most spray applications. 3/8" wire stickout, volts 17 and wire feed speed 150 IPM = 50-60 amps due to the resistive heating of the wire between the tip and the arc the weld current drops to the level required to maintain the set voltage. Lincoln electric easy MIG welder $400.00 220 Lincoln Mig Welder Muskoka 17/07/2022 Located in Huntsville. Laser welding is also a good option; they can tune the power for thin aluminum foils as well as micromachining. A 200- amp unit can weld between 5/16" steel. $400. The bottom Right Hand Side knob (looking at the machine) looks like it may be used for setting how long the wire is fed for (spot welding). In MIG welding, the amperage is set with the wire speed for the wire diameter you use. However, the higher the amperage and voltage of a welder, the greater the thickness it can work with. Lincoln MIG Welding Settings Chart for E71T-GS + Flux Core + Tubular electrodes. It will do 4 minutes of continuous welding and need 6 The wire feed speed is measured in inches per minute and controls the welding amperage in MIG welding. Dip or Short Circuit Mode In the dip or short circuit, the wire (electrode) touches the work piece and a short circuit is created.  To fully comprehend how the machinery operates, one must first grasp the MIG welding process using the aluminium MIG welding settings chart as a guide. When you know those, you can easily determine how many amps you will need for your welder to weld aluminum perfectly. kinda like setting the fuel mixture on a carburetor. You can use MIG wire as a filler and then start at 20 amps. Hobart Has The Solution Poster Download. For example, both 0.024- and 0.30-inch solid wires can be used to weld 24-gauge material using a welding current of 30 to 50 amps and travel speeds of 10 to 20 inches per minute (ipm). You can easily weld 22 gauge 0.8mm panel steel to inch 6mm plate. It welds hot for a 200-amp welder, which gives you good options for different types of welding, including heavy-gauge sections. A 180 amp MIG welder is capable of fusing up to an amount of 0.035 inches. The SUNGOLDPOWER 200A MIG Welder is a lower-priced, lower-quality machine than the Weldpro 155 Amp Inverter MIG Welder. This method has the benefit of creating a small, quickly solidifying weld puddle.

To fully comprehend how the machinery operates, one must first grasp the MIG welding process using the aluminium MIG welding settings chart as a guide. When you know those, you can easily determine how many amps you will need for your welder to weld aluminum perfectly. kinda like setting the fuel mixture on a carburetor. You can use MIG wire as a filler and then start at 20 amps. Hobart Has The Solution Poster Download. For example, both 0.024- and 0.30-inch solid wires can be used to weld 24-gauge material using a welding current of 30 to 50 amps and travel speeds of 10 to 20 inches per minute (ipm). You can easily weld 22 gauge 0.8mm panel steel to inch 6mm plate. It welds hot for a 200-amp welder, which gives you good options for different types of welding, including heavy-gauge sections. A 180 amp MIG welder is capable of fusing up to an amount of 0.035 inches. The SUNGOLDPOWER 200A MIG Welder is a lower-priced, lower-quality machine than the Weldpro 155 Amp Inverter MIG Welder. This method has the benefit of creating a small, quickly solidifying weld puddle.  you set the dial BUT as already mentioned you really don't need to do this on the HH140 or a lot of machines as a hobby welder. MMA TIG, MIG MAG CO2 & SAW Welding Chart with TIG, MIG & SAW Wire Size and Amperes. Check the user manual of your welder to check the manufacturers recommendations for the wire size chart; 0.030 Flux Core Good for welding a minimum of 18 gauge and up to around inch thickness. I have an old (80's?) Weld a wide range of materials with MIG & Flux welders from Harbor Freight. only weld flat and horizontal. Its a simple procedure that results in a more clean and efficient method of joining two metal pieces together. 330-415. The wire will short circuit the base metal between 90 and 200 times per second. 7014 electrode is mainly used on heavy sheet metal and building frames of all sorts. 1/8 or 3.2 mm. In general, you can expect your MIG welder to be able to weld .001 thickness for every amp. Read More. Volts. Additionally, we made the most complete stick welding rod chart PDF on the internet with over 220 electrodes. NOTICE - Each welding application is unique. Current (Ampere) MIG Wire Size (mm) Diode Based Model Miller MIG Welders ESAB MIG Welders WIRE SIZE CHART. For example, if the wire size is 0.23 inches ( used for sheet metal ), then you need to multiply by 3.5 inches per amp, which leads to 3.5 x 125 = 437.5 ipm. A common rule of thumb is that you will need 1 amp for every 0.001 inches of metal you are going to weld when other variables are constant. This means that the power signal of the MIG 175 should remain on for 30% of the time and off 70% of the time at 130 amps of power. For example: A .030 wire with 200 ipm (inches per minute) gives 100A, but with 300 ipm 150A. It is perfect for maintenance and repair jobs, Input Power. For example, 3/32 rod diameter would be (.094) 90 amps, 1/8 rod diameter would be (.125) 125 amps, 5/32 rod diameter would be (.157) 155 amps. Nevertheless, the filler rods are sold with ER in their name, not just R.. Use the chart below to set the wire speed based on the wire size. WELDING HELMET; REVIEWS; ACCESSORIES; 180 -200 amp: 9.5 mm: 250-275 amp: 11.1 mm: 280-300 amp: Over 12.7 mm: 300-325 amp: The amps settings can be different depending on the manufacturer.

you set the dial BUT as already mentioned you really don't need to do this on the HH140 or a lot of machines as a hobby welder. MMA TIG, MIG MAG CO2 & SAW Welding Chart with TIG, MIG & SAW Wire Size and Amperes. Check the user manual of your welder to check the manufacturers recommendations for the wire size chart; 0.030 Flux Core Good for welding a minimum of 18 gauge and up to around inch thickness. I have an old (80's?) Weld a wide range of materials with MIG & Flux welders from Harbor Freight. only weld flat and horizontal. Its a simple procedure that results in a more clean and efficient method of joining two metal pieces together. 330-415. The wire will short circuit the base metal between 90 and 200 times per second. 7014 electrode is mainly used on heavy sheet metal and building frames of all sorts. 1/8 or 3.2 mm. In general, you can expect your MIG welder to be able to weld .001 thickness for every amp. Read More. Volts. Additionally, we made the most complete stick welding rod chart PDF on the internet with over 220 electrodes. NOTICE - Each welding application is unique. Current (Ampere) MIG Wire Size (mm) Diode Based Model Miller MIG Welders ESAB MIG Welders WIRE SIZE CHART. For example, if the wire size is 0.23 inches ( used for sheet metal ), then you need to multiply by 3.5 inches per amp, which leads to 3.5 x 125 = 437.5 ipm. A common rule of thumb is that you will need 1 amp for every 0.001 inches of metal you are going to weld when other variables are constant. This means that the power signal of the MIG 175 should remain on for 30% of the time and off 70% of the time at 130 amps of power. For example: A .030 wire with 200 ipm (inches per minute) gives 100A, but with 300 ipm 150A. It is perfect for maintenance and repair jobs, Input Power. For example, 3/32 rod diameter would be (.094) 90 amps, 1/8 rod diameter would be (.125) 125 amps, 5/32 rod diameter would be (.157) 155 amps. Nevertheless, the filler rods are sold with ER in their name, not just R.. Use the chart below to set the wire speed based on the wire size. WELDING HELMET; REVIEWS; ACCESSORIES; 180 -200 amp: 9.5 mm: 250-275 amp: 11.1 mm: 280-300 amp: Over 12.7 mm: 300-325 amp: The amps settings can be different depending on the manufacturer.