This toxic gas means you must protect yourself and ensure you are not breathing the fumes when welding SS. Hope that helps Stick welding is much more forgiving than other welding processes; however, inclusions and impurities are often caused by dirty surfaces.

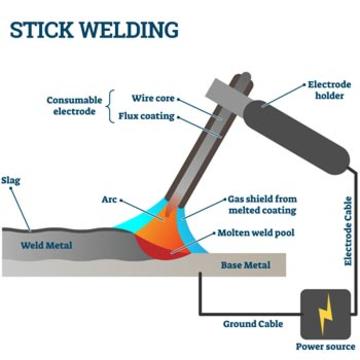

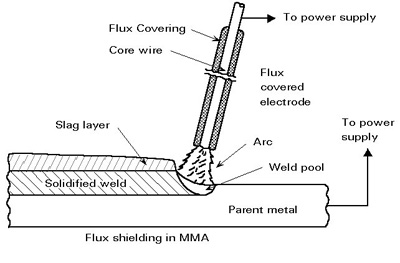

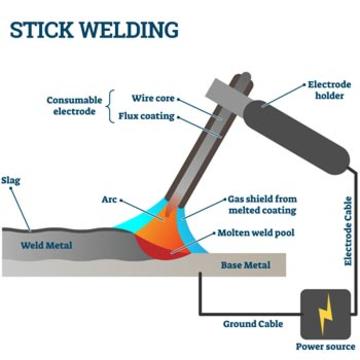

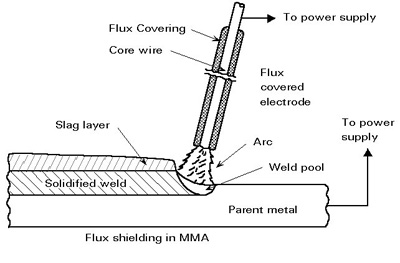

Stainless steel does not tolerate contamination well. Electrodes (the wire or stick must be carefully selected for the weld), Shielding gas (for MIG and TIG, and possibly flux-cored), Grinder/wire brush/solvent to clean the metal, Welding table (for smaller, in-shop work), Safety glasses (for grinding and other ancillary work), Welding boots (25% of all welding accidents involve foot injuries), MIG Pliers (handy to have for all welding processes). Stick electrodes have an external coating that contains flux. Cleaning is usually done with pickling pastes, grinders/wire brushes/abrasives, or electrochemical cleaning. Im guessing 308L or 316L based on your article. This site is operated by Darn Good Investments, Inc. WeldingMastermind.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. You must pick the right gas. 304 and 316 Stainless Steels can both be welded with 316 filler wire. The chamfer will allow the weld to flow in and leaves a flusher result. Stainless rods get hotter quicker though so you may need to tweak the amps down a bit as you go. First time ive stumbled on your site and its so refreshing to get the answer im looking for instantly and clearly you are now bookmarked l. You need to replace the filler rod now and then, meaning long welds will have stops and starts. These are often called dual shielded wires and are widely available (obtaining true gasless flux-cored SS wire is harder). Hope Ive helped, cheers Graham, Thanks for the kind and thoughtful comments, sorry I havent been able to respond sooner. Also, you avoid contaminating the SS with carbon in the HAZ, which can cause rust in the SS pieces. So, be sure to note what polarity you need for the flux-cored wire you have, and ensure your machine is set appropriately.

Fine heat control helps to minimize warping in a stainless steel piece. Yes! Here are some key points to look out for: Join my weekly newsletter and receive helpful tips, tools, and theories about welding and joining. Cheers In many cases, the melting point of the two metals will be far apart, creating a challenge.

.jpg)

If your welder has it, the ability to tweak the heat, or amps, as you weld helps to minimize excess heat and the resulting warping in the SS. But like all welding, anyone can learn with enough practice.

Stainless steel warps when exposed to excess heat. Generally speaking, though, going with some commonly available diameters will make your welding project more affordable since you can reuse the electrodes for other projects. You need to assess the risks and decide if they are acceptable for the intended application. We mentioned that near the beginning of this article. Carbon increases the resistance against intergranular corrosion. It is commonly 3/32 but can go up to 1/4 inch. Thanks for your very informative blog. This site also participates in affiliate programs with other sites. A low carbon content, generally speaking, makes it easier to weld. Also, if your welder has a pulse setting, use it. In some cases, nitrogen (N2) and hydrogen (H2) are added to achieve special properties. If you want those sleek, professional-looking beads, a TIG welder should be your first choice. Otherwise, you can have issues with slag inclusions in your weld. Since it is why you are here, lets clear up the most commonly asked questions first. That will create excess heat in the stainless steel. Plus, you must replace the consumable electrode often. So, the learning curve is not as bad as some make it. In general, you dont want to move too slow. Clean the surface to be welded with a wire brush. 2006 - 2022 WeldGuru.com - All rights reserved. Would you agree? But MIG, flux-cored, and stick welders can all weld it, too. What is It Used For? Proper fit-up allows you to use the proper amount of filler material and eliminates the need to fill gaps. That means the composition of the wire is more complex than a solid MIG wire. Flux means these electrodes produce slag that you must deal with, and controlling the heat in the metal can be a challenge. Hope that helps, Would you agree? We respect your privacy and promise not to spam. Stick is simple and easy to use, but it does produce a lot of spatter. If you apply excess heat, stainless steel can warp, or it may even distort as it cools. i have welded stainless to mild with mild wire a few times.

No exceptions, so be meticulous. As long as you use a suitable welding rod or wire for the type of Stainless Steel you intend welding, all should be pretty straight forward. Another important property of mild steel is that apart from the main ingredients, iron, and Carbon, not many other alloy elements are contained in the steel. With 300 series Stainless Steels, you should always weld a part with a rod that is the same grade, or higher. Therefore pick the electrode that is easier to access for you before you lose yourself in optimization details. The link is only valid for 60 minutes. Tig would allow you to better control the size of build up to minimise distortion.

Both diameters are easy to source for stainless steel rods. A taper of no more than 2.5 times the electrode diameter allows for a focused arc that produces deep, thin beads, and a small heat-affected zone (HAZ). Statight forward especially for a starter like myself. For this reason alone, some will say welding stainless is a more complicated, unforgiving job best suited for advanced users. This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.. Glad you found the article and our website useful. Tap the electrode on the steel until it strikes an arc and begin to weave the electrode stick from side to side and always keep the arc a half a centimeter or less away from the piece of steel you are welding. How to Weld Sheet Metal or Thin Stock (For Beginners), Beginners Guide: MIG Welding Aluminum (with Charts). Plus, you need to avoid varying this distance between the nozzle and metal as you weld. If using a double-shielded wire (flux and shielding gas together), be sure to have shielding gas on hand. Please confirm the subscription Email in your inbox. If you dont trim every time, you can get a silicon blob at the tip of your wire that can mess up your start. This profile helps with the fit-up, but it also allows you to make stronger, better-looking welds, too. Cheers Graham. Experienced welders should set the pulse rate at 100 pulses per second (PPS) to start and go up as high as 500 PPS. What are standard diameters? Once this armor is pierced, stainless steel can rust as well. Be sure that the pieces are aligned properly and that there are no gaps or variations in the joint.

One can observe this, for example, in the kitchen or other stainless steel appliances that have some deeper scratches and are exposed to water. But SS is different than carbon steel, and it is necessary for many jobs. Rusting of stainless steel occurs when the protective chromium layer gets damaged. But for several reasons, this is a tricky challenge with special considerations. Thanks for your pleasant and informative site. Allow the weld to cool for a minute, then use the welding hammer to chip off the slag from the top of the weld. Im proficient in all possesses, Hi Steve, not in my experience (assuming its a regular Stainless Steel, 304 or 316 for example). Im welding stainless firplace. For FCAW stainless, a 10-degree drag angle should generally work fine as a starting point. Excess heat can cause stainless steel to lose its corrosion resistance. What Kind of Welder is Best for Stainless Steel? If you liked this article, have a look at my other articles I wrote about the topic! Plug your welder into a 220V outlet and then plug in your ground cord and welder electrode holder cord into the welder. With thicker pieces, the edges will need to be beveled or chamfered. Now the Client is asking expalnation. Thanks! 308 and 316 grades of Welding Rod/Wire are often modified from the basic alloy. Imaging doing it yourself to save money and learn a valuable trade. The pipes are impact tested at room temperature. The second thing to do is clean your finished weld completely, including discoloration. It can contaminate the weld, and yep rust. You must also pay attention to the tungsten electrode type. It has become a bit of a pet project, as I want to learn more about the details about welding. Third, this will sound repetitive by now, but keep your heat down. The problem is that the weld can corrode, and you need to coat the bead to keep it from rusting. Be sure to use the right diameter wire, too. Gaps of variations in the joint width require excess filler material, which adds more heat to the weld. Graham, As usual graham your bogs are straight to the point , not complicated , easy to follow and very helpfull. Stainless Steel doesnt conduct heat as quickly as Mild Steel, so you normally need a little less power. Additionally, higher voltage settings need to be used, which wets out the puddle that allows a flatter face and feathers in the toes of the weld. Too many assume TIG welding is the only process that welds SS. Plus, you do need to use an expensive shielding gas. Also, when flux-core welding, trim the wire tip every time you lay a bead. so i could get away with 308l for all the joins?

If you are using a more specialised Stainless Steel, it would be wise to look up the recommended welding procedure before welding. i only have 6 joints to weld all 2" in diameter but strength and crack prevention is a must so i think ill go with stick welding. Save my name, email, and website in this browser for the next time I comment. But with stick welding, you may want to try a much steeper angle. The cost of welding work ranges from $25-$50 an hour. Even trace amounts can create an issue. Would Silver Solder of Mig welding be the best process for an amature in both processes? document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Welding Equipment & Welding Supplies since 1993.

Looking to have stainless steel bar drilled and a high tensile bolt inserted then welded together. Stainless Steel is more prone to distortion. Another term for mild steel is low carbon steel, which refers to the alloy composite.

So, the electrode used must have the right diameter. Welding stainless steel is becoming a highly sought-after skill with the growing use of stainless steel in products; stainless steel welding projects range from welding a cracked sink to welding a leak on a grain bin. While not as easy as welding mild steel, it is doable with a little knowledge and practice for just about everyone with the right equipment.

You might be seeing a pattern here, but the selection of your filler material matters in every welding process. Will welds crack if 308 stainless filler rod is used to weld 316 stainless material? So, you need to be careful when selecting/buying wire. Thanks Graham. Regards Graham. If the metal is very thin, consider taking the kettle to a pro for Tig Welding, will cost more, but would be safest option to keep the much loved kettle going. If the added cost of MIG welding SS is an issue, flux-cored welding allows you to use less expensive CO2 or even no shielding gas. Compared to mild steel, this is achieved by alloy elements that are added to the steel, mainly chromium. But if not, most SS welds use a slightly higher wire feed speed (WFS) than what you would use with mild steel. Which size you need depends on variables like polarity, amperage, joint size, base metal thickness. Also, most common nails are made out of mild steel. You MUST use the right filler material, shielding gas, settings, etc., for each alloy. Electrode size makes a difference in a TIG welder. If you intend to weld more volume, this might be the right choice for you. However, hydrogen should not be used when welding martensitic, ferritic, or duplex grades. Cheers Graham, Good day sir!we would like to inquire regarding the possible use of 308 stainless welding rod in replacement of 316 stainless welding for use of palm rudder strut post of ship/vessel.Based on the palm rudder nameplate,316 was indicated to be used.pls let us know.thanks, Hi Jhoel So please share your technical justification with code/standard evidence. But you must first set your maximum amps on the machine. A property that benefits from a low carbon content is ductility (e.g., signposts would be made out of mild steel). 316 is Food Grade Stainless Steel, so you should not use 308 filler if the job is going into a food environment. First, be sure to provide a good blanket of shielding gas. I have all 3 processes but would still mig certain things that may be better with tig as i am better at mig. 304/304L This is the most common general purpose Stainless Steel and is welded with one of the 308 spec Welding Rods or Wires. Welding Stainless Steel is not vastly different to welding Mild Steel, which is why I say its no big deal, however, there are a couple of things worth noting. Each process will yield a slightly different result and will require some learning and skill to accomplish. Also, with stick and flux-cored welding, you can tell if your speed is off by the resulting bead. With slag, you drag. I hope you found this useful, if things work out well for you, please feel free to post some pictures of your achievements on our Facebook Page. However, if it is a flange it wont last at all, flanges are 10mm and 15mm bends 3mm and tube 2mm, personally i would prefer to tig it with a purge, second choice would be mig with argoshield or similar but it could be done with arc. In the case of mild steel, grinding the dark protective layer is optional for. Yeah, welding stainless with MAG/MIG you need stainless wire and Stainshield. The slag encapsulation of the weld limits the absorption of carbon, making using shielding gas with high CO2 content possible. The first step is to obtain and install the right wire alloy and size for the weld you want to conduct. It is essential to use the correct electrode. Therefore allowing rust. Stainless steel also clearly shows every imperfection in the weld. Also, be sure to set your flow rate properly. Most frequently used to weld base metals of similar composition. Remember? Plus, since there is no shielding gas, you can weld in windy conditions. your heat input, on the low side to keep the problem at bay. You need to understand the two metals you are welding and use the correct filler material.

A bit about myself: I am a certified international welding engineer (IWE) who worked in different welding projects for TIG, MIG, MAG, and Resistance Spot welding. On stainless work, that can be a problem. Adding Silicon will make the molten weld metal slightly more fluid and so flow better. Then, there are particulars for the various welding processes, which we detail below. The gear needed to weld SS will not be that different from welding other metals. And the application of 316L is 1 inch diameter pipe with 3.38 mm wall thickness. A lot of Mig and Tig Wire may be 308LSi & 316LSi, this denotes Low Carbon and added Silicon. I have a much loved 316 stainless steel stove top kettle with 2 pinholes in the base from being left on a live gas ring. It needs to be the right alloy for the weld you intend, no matter what type of welder you use. You will need Rods/Wire that at least matches the grade of Stainless youll be using. Your email address will not be published. Stainless steel looks great and resists corrosion. The various welding processes have varying depositions rates, and there is no substitute for experience to learn how it varies with your welders. Plus, the weld looks better if the bead width is consistent.

Place an electrode into the welder electrode holder, position the electrode near where the weld will start and pull your helmet over your face. While that was the short answer, I have added some details and pieces of knowledge to help you create successful stainless steel to mild steel joint with stick welding. The bottom line, welding dissimilar metals is a risk. The amperage settings should be listed in the welder manual or a chart printed on the welder, or you can find recommendations pretty easily if they arent. Yeah, if you are welding mild to stainless you might as well use mild steel wire/rods cos its going to rust anyway.

Hope that helps

Any suggestions? But normally, you will focus only on the particular alloys you use, not all of them. Also, do not use a steel wire brush. Titanium Unlimited 140 Review Is It Worth It? Silver Soldering Holes has a few challenges, as does Silver Soldering Stainless Steel. This advice works, in general, all FCAW or stick welding. If the electrode tapers more than 2.5 times its diameter, the arc starts to fan out, resulting in less penetration and a larger HAZ. Welding Stainless Steel is no big deal. Youll probably have porosity issues, and the weld might be prone to rust. So, it makes sense, set your amps, a.k.a. If the metal is not too thin, I would opt for Mig. Sign up and join 10,000+ other learners and get free welding articles and tips sent straight to your inbox. i don't find 2mm to be a problem with stick.

Fast weld travel: The weld will turn out extra ropey, and the weld bead will be too narrow. Switching to a stainless steel filler alloy that matches the base metal avoids the problem. To prevent this from happening, you can do a few things. If you are on a ladder or other hard-to-reach areas, finger control may be necessary.

If you weld stainy with mild steel consumables you might as well use mild steel for the whole job. But when it comes to welding it, things can get complicated. But helium (He) may be added to increase penetration and fluidity of the weld pool. Some even think it is too hard to weld stainless unless you have decades of experience. After setting up your welder for stainless steel, you now need to prepare the metal before welding. So, you typically do not need to check on it. Regards Graham. And around 3 meters length in total.piping It is not a replacement for manufacturers directions and is only to provide reminders for experienced welders. Dissimilar metals can be welded together, including stainless steel. It will vary with the SS alloy and other variables like thickness. You do not want to use a pure inert shielding gas, such as helium or argon, for SS MIG welding. Thanks. Kind Regards, Graham.

Thanks for the kind and generous comments, sorry I havent been able to respond sooner.

This layer protects the main element of stainless steel, iron, from direct contact with oxygen. If food is going to be coming into contact with the grates, youll need to use 316 material and 316 rods/wire, if no food contact, 304 material and 308 rods/wire will be fine.

Stainless steel is sensitive to atmospheric gasses, and a tri-mix of 90% helium, 7.5% argon, and 2.5% carbon dioxide is popular. For a better experience, please enable JavaScript in your browser before proceeding. You must log in or register to reply here.

But with flux-cored welding, the consumable electrode wire is the filler material, and it carries the flux in the core of the wire to shield the weld. Make sure to follow the manufacturers recommendations that come with the package to get the most out of your electrodes. As I was looking for more affordable options to stick weld dual-material joints with stainless steel, I came across this question. Applications for stainless steel are everywhere where high standards in cleanliness have to be kept, for example, kitchens, pharmaceutical or food production, and aerospace. http://www.ebay.co.uk/itm/MIG-WELDI832?pt=LH_DefaultDomain_3&hash=item2a32b33940. Thanks for the comment, glad you found the article useful.

For SS, many assume you need a shielding gas. Electrodes, once open, have a shelf live. Make sure all surfaces are cleaned. Dont worry, your email address wont be added to a database or shared and you wont receive any unsolicited email. Regards Graham. The manufacturers usually apply the correct flux coating to the SS alloy used to make the stick. I submitted a proposal for welding of A312 TP304L, TP316 and TP316L with ER316L. would something like this be suitable for all the joins? If you state roughly your location, maybe there is someone on here nearby who could tig it for you. Sorry Ive not been able to reply earlier. What do You Need to Weld Stainless Steel? While wind can be a problem, these wires handle out-of-position welds better. https://www.metalsupermarkets.com/what-is-mild-steel/, https://www.metalsupermarkets.com/difference-between-stainless-steel-galvanized-steel/. You dont have to constantly swap in new electrodes/filler rods as you must with TIG and stick welders. There are drawbacks to TIG welding SS, though. Plus, its durable and strong. Disclaimer: Weldguru.com is based on information from multiple sources including U.S. Army Operator Circulars, O.S.H.A and our own first hand experience with welding. Another issue with welding stainless, there are a lot of different alloys. As already stated, SS is sensitive to reactive gasses, and that means it requires a good blanket to prevent weld contamination. While welding stainless steel to a dissimilar metal like mild steel changes nothing on the stick welding process or welder setup compared to joining similar materials, the most crucial factor for a successful joint is the electrode choice. The thicker the filler rod/wire, the more heat you need. Regards dell, Your email address will not be published.

But some SS alloys may require a different color electrode. hey lads, iv been welding for a few years on cars, but iv always used gasless wire as my jobs never warranted a gas bottle, iv also had a fair amount of time on my arc welder for the heavier jobs iv needed to do. So welding 304/308 stainless with 316 filler is no problem. For example, the inclusion of hydrogen gives a similar but stronger effect compared to adding helium. Purchase an AWS E308 stick electrode to weld stainless steel.

Sitemap 1

Stainless steel does not tolerate contamination well. Electrodes (the wire or stick must be carefully selected for the weld), Shielding gas (for MIG and TIG, and possibly flux-cored), Grinder/wire brush/solvent to clean the metal, Welding table (for smaller, in-shop work), Safety glasses (for grinding and other ancillary work), Welding boots (25% of all welding accidents involve foot injuries), MIG Pliers (handy to have for all welding processes). Stick electrodes have an external coating that contains flux. Cleaning is usually done with pickling pastes, grinders/wire brushes/abrasives, or electrochemical cleaning. Im guessing 308L or 316L based on your article. This site is operated by Darn Good Investments, Inc. WeldingMastermind.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. You must pick the right gas. 304 and 316 Stainless Steels can both be welded with 316 filler wire. The chamfer will allow the weld to flow in and leaves a flusher result. Stainless rods get hotter quicker though so you may need to tweak the amps down a bit as you go. First time ive stumbled on your site and its so refreshing to get the answer im looking for instantly and clearly you are now bookmarked l. You need to replace the filler rod now and then, meaning long welds will have stops and starts. These are often called dual shielded wires and are widely available (obtaining true gasless flux-cored SS wire is harder). Hope Ive helped, cheers Graham, Thanks for the kind and thoughtful comments, sorry I havent been able to respond sooner. Also, you avoid contaminating the SS with carbon in the HAZ, which can cause rust in the SS pieces. So, be sure to note what polarity you need for the flux-cored wire you have, and ensure your machine is set appropriately.

Stainless steel does not tolerate contamination well. Electrodes (the wire or stick must be carefully selected for the weld), Shielding gas (for MIG and TIG, and possibly flux-cored), Grinder/wire brush/solvent to clean the metal, Welding table (for smaller, in-shop work), Safety glasses (for grinding and other ancillary work), Welding boots (25% of all welding accidents involve foot injuries), MIG Pliers (handy to have for all welding processes). Stick electrodes have an external coating that contains flux. Cleaning is usually done with pickling pastes, grinders/wire brushes/abrasives, or electrochemical cleaning. Im guessing 308L or 316L based on your article. This site is operated by Darn Good Investments, Inc. WeldingMastermind.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. You must pick the right gas. 304 and 316 Stainless Steels can both be welded with 316 filler wire. The chamfer will allow the weld to flow in and leaves a flusher result. Stainless rods get hotter quicker though so you may need to tweak the amps down a bit as you go. First time ive stumbled on your site and its so refreshing to get the answer im looking for instantly and clearly you are now bookmarked l. You need to replace the filler rod now and then, meaning long welds will have stops and starts. These are often called dual shielded wires and are widely available (obtaining true gasless flux-cored SS wire is harder). Hope Ive helped, cheers Graham, Thanks for the kind and thoughtful comments, sorry I havent been able to respond sooner. Also, you avoid contaminating the SS with carbon in the HAZ, which can cause rust in the SS pieces. So, be sure to note what polarity you need for the flux-cored wire you have, and ensure your machine is set appropriately.  Fine heat control helps to minimize warping in a stainless steel piece. Yes! Here are some key points to look out for: Join my weekly newsletter and receive helpful tips, tools, and theories about welding and joining. Cheers In many cases, the melting point of the two metals will be far apart, creating a challenge.

Fine heat control helps to minimize warping in a stainless steel piece. Yes! Here are some key points to look out for: Join my weekly newsletter and receive helpful tips, tools, and theories about welding and joining. Cheers In many cases, the melting point of the two metals will be far apart, creating a challenge. .jpg) If your welder has it, the ability to tweak the heat, or amps, as you weld helps to minimize excess heat and the resulting warping in the SS. But like all welding, anyone can learn with enough practice.

If your welder has it, the ability to tweak the heat, or amps, as you weld helps to minimize excess heat and the resulting warping in the SS. But like all welding, anyone can learn with enough practice.  Stainless steel warps when exposed to excess heat. Generally speaking, though, going with some commonly available diameters will make your welding project more affordable since you can reuse the electrodes for other projects. You need to assess the risks and decide if they are acceptable for the intended application. We mentioned that near the beginning of this article. Carbon increases the resistance against intergranular corrosion. It is commonly 3/32 but can go up to 1/4 inch. Thanks for your very informative blog. This site also participates in affiliate programs with other sites. A low carbon content, generally speaking, makes it easier to weld. Also, if your welder has a pulse setting, use it. In some cases, nitrogen (N2) and hydrogen (H2) are added to achieve special properties. If you want those sleek, professional-looking beads, a TIG welder should be your first choice. Otherwise, you can have issues with slag inclusions in your weld. Since it is why you are here, lets clear up the most commonly asked questions first. That will create excess heat in the stainless steel. Plus, you must replace the consumable electrode often. So, the learning curve is not as bad as some make it. In general, you dont want to move too slow. Clean the surface to be welded with a wire brush. 2006 - 2022 WeldGuru.com - All rights reserved. Would you agree? But MIG, flux-cored, and stick welders can all weld it, too. What is It Used For? Proper fit-up allows you to use the proper amount of filler material and eliminates the need to fill gaps. That means the composition of the wire is more complex than a solid MIG wire. Flux means these electrodes produce slag that you must deal with, and controlling the heat in the metal can be a challenge. Hope that helps, Would you agree? We respect your privacy and promise not to spam. Stick is simple and easy to use, but it does produce a lot of spatter. If you apply excess heat, stainless steel can warp, or it may even distort as it cools. i have welded stainless to mild with mild wire a few times.

Stainless steel warps when exposed to excess heat. Generally speaking, though, going with some commonly available diameters will make your welding project more affordable since you can reuse the electrodes for other projects. You need to assess the risks and decide if they are acceptable for the intended application. We mentioned that near the beginning of this article. Carbon increases the resistance against intergranular corrosion. It is commonly 3/32 but can go up to 1/4 inch. Thanks for your very informative blog. This site also participates in affiliate programs with other sites. A low carbon content, generally speaking, makes it easier to weld. Also, if your welder has a pulse setting, use it. In some cases, nitrogen (N2) and hydrogen (H2) are added to achieve special properties. If you want those sleek, professional-looking beads, a TIG welder should be your first choice. Otherwise, you can have issues with slag inclusions in your weld. Since it is why you are here, lets clear up the most commonly asked questions first. That will create excess heat in the stainless steel. Plus, you must replace the consumable electrode often. So, the learning curve is not as bad as some make it. In general, you dont want to move too slow. Clean the surface to be welded with a wire brush. 2006 - 2022 WeldGuru.com - All rights reserved. Would you agree? But MIG, flux-cored, and stick welders can all weld it, too. What is It Used For? Proper fit-up allows you to use the proper amount of filler material and eliminates the need to fill gaps. That means the composition of the wire is more complex than a solid MIG wire. Flux means these electrodes produce slag that you must deal with, and controlling the heat in the metal can be a challenge. Hope that helps, Would you agree? We respect your privacy and promise not to spam. Stick is simple and easy to use, but it does produce a lot of spatter. If you apply excess heat, stainless steel can warp, or it may even distort as it cools. i have welded stainless to mild with mild wire a few times.  No exceptions, so be meticulous. As long as you use a suitable welding rod or wire for the type of Stainless Steel you intend welding, all should be pretty straight forward. Another important property of mild steel is that apart from the main ingredients, iron, and Carbon, not many other alloy elements are contained in the steel. With 300 series Stainless Steels, you should always weld a part with a rod that is the same grade, or higher. Therefore pick the electrode that is easier to access for you before you lose yourself in optimization details. The link is only valid for 60 minutes. Tig would allow you to better control the size of build up to minimise distortion.

No exceptions, so be meticulous. As long as you use a suitable welding rod or wire for the type of Stainless Steel you intend welding, all should be pretty straight forward. Another important property of mild steel is that apart from the main ingredients, iron, and Carbon, not many other alloy elements are contained in the steel. With 300 series Stainless Steels, you should always weld a part with a rod that is the same grade, or higher. Therefore pick the electrode that is easier to access for you before you lose yourself in optimization details. The link is only valid for 60 minutes. Tig would allow you to better control the size of build up to minimise distortion.  Both diameters are easy to source for stainless steel rods. A taper of no more than 2.5 times the electrode diameter allows for a focused arc that produces deep, thin beads, and a small heat-affected zone (HAZ). Statight forward especially for a starter like myself. For this reason alone, some will say welding stainless is a more complicated, unforgiving job best suited for advanced users. This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.. Glad you found the article and our website useful. Tap the electrode on the steel until it strikes an arc and begin to weave the electrode stick from side to side and always keep the arc a half a centimeter or less away from the piece of steel you are welding. How to Weld Sheet Metal or Thin Stock (For Beginners), Beginners Guide: MIG Welding Aluminum (with Charts). Plus, you need to avoid varying this distance between the nozzle and metal as you weld. If using a double-shielded wire (flux and shielding gas together), be sure to have shielding gas on hand. Please confirm the subscription Email in your inbox. If you dont trim every time, you can get a silicon blob at the tip of your wire that can mess up your start. This profile helps with the fit-up, but it also allows you to make stronger, better-looking welds, too. Cheers Graham. Experienced welders should set the pulse rate at 100 pulses per second (PPS) to start and go up as high as 500 PPS. What are standard diameters? Once this armor is pierced, stainless steel can rust as well. Be sure that the pieces are aligned properly and that there are no gaps or variations in the joint.

Both diameters are easy to source for stainless steel rods. A taper of no more than 2.5 times the electrode diameter allows for a focused arc that produces deep, thin beads, and a small heat-affected zone (HAZ). Statight forward especially for a starter like myself. For this reason alone, some will say welding stainless is a more complicated, unforgiving job best suited for advanced users. This post contains affiliate links, and I will be compensated if you make a purchase after clicking on my links.. Glad you found the article and our website useful. Tap the electrode on the steel until it strikes an arc and begin to weave the electrode stick from side to side and always keep the arc a half a centimeter or less away from the piece of steel you are welding. How to Weld Sheet Metal or Thin Stock (For Beginners), Beginners Guide: MIG Welding Aluminum (with Charts). Plus, you need to avoid varying this distance between the nozzle and metal as you weld. If using a double-shielded wire (flux and shielding gas together), be sure to have shielding gas on hand. Please confirm the subscription Email in your inbox. If you dont trim every time, you can get a silicon blob at the tip of your wire that can mess up your start. This profile helps with the fit-up, but it also allows you to make stronger, better-looking welds, too. Cheers Graham. Experienced welders should set the pulse rate at 100 pulses per second (PPS) to start and go up as high as 500 PPS. What are standard diameters? Once this armor is pierced, stainless steel can rust as well. Be sure that the pieces are aligned properly and that there are no gaps or variations in the joint.  One can observe this, for example, in the kitchen or other stainless steel appliances that have some deeper scratches and are exposed to water. But SS is different than carbon steel, and it is necessary for many jobs. Rusting of stainless steel occurs when the protective chromium layer gets damaged. But for several reasons, this is a tricky challenge with special considerations. Thanks for your pleasant and informative site. Allow the weld to cool for a minute, then use the welding hammer to chip off the slag from the top of the weld. Im proficient in all possesses, Hi Steve, not in my experience (assuming its a regular Stainless Steel, 304 or 316 for example). Im welding stainless firplace. For FCAW stainless, a 10-degree drag angle should generally work fine as a starting point. Excess heat can cause stainless steel to lose its corrosion resistance. What Kind of Welder is Best for Stainless Steel? If you liked this article, have a look at my other articles I wrote about the topic! Plug your welder into a 220V outlet and then plug in your ground cord and welder electrode holder cord into the welder. With thicker pieces, the edges will need to be beveled or chamfered. Now the Client is asking expalnation. Thanks! 308 and 316 grades of Welding Rod/Wire are often modified from the basic alloy. Imaging doing it yourself to save money and learn a valuable trade. The pipes are impact tested at room temperature. The second thing to do is clean your finished weld completely, including discoloration. It can contaminate the weld, and yep rust. You must also pay attention to the tungsten electrode type. It has become a bit of a pet project, as I want to learn more about the details about welding. Third, this will sound repetitive by now, but keep your heat down. The problem is that the weld can corrode, and you need to coat the bead to keep it from rusting. Be sure to use the right diameter wire, too. Gaps of variations in the joint width require excess filler material, which adds more heat to the weld. Graham, As usual graham your bogs are straight to the point , not complicated , easy to follow and very helpfull. Stainless Steel doesnt conduct heat as quickly as Mild Steel, so you normally need a little less power. Additionally, higher voltage settings need to be used, which wets out the puddle that allows a flatter face and feathers in the toes of the weld. Too many assume TIG welding is the only process that welds SS. Plus, you do need to use an expensive shielding gas. Also, when flux-core welding, trim the wire tip every time you lay a bead. so i could get away with 308l for all the joins?

One can observe this, for example, in the kitchen or other stainless steel appliances that have some deeper scratches and are exposed to water. But SS is different than carbon steel, and it is necessary for many jobs. Rusting of stainless steel occurs when the protective chromium layer gets damaged. But for several reasons, this is a tricky challenge with special considerations. Thanks for your pleasant and informative site. Allow the weld to cool for a minute, then use the welding hammer to chip off the slag from the top of the weld. Im proficient in all possesses, Hi Steve, not in my experience (assuming its a regular Stainless Steel, 304 or 316 for example). Im welding stainless firplace. For FCAW stainless, a 10-degree drag angle should generally work fine as a starting point. Excess heat can cause stainless steel to lose its corrosion resistance. What Kind of Welder is Best for Stainless Steel? If you liked this article, have a look at my other articles I wrote about the topic! Plug your welder into a 220V outlet and then plug in your ground cord and welder electrode holder cord into the welder. With thicker pieces, the edges will need to be beveled or chamfered. Now the Client is asking expalnation. Thanks! 308 and 316 grades of Welding Rod/Wire are often modified from the basic alloy. Imaging doing it yourself to save money and learn a valuable trade. The pipes are impact tested at room temperature. The second thing to do is clean your finished weld completely, including discoloration. It can contaminate the weld, and yep rust. You must also pay attention to the tungsten electrode type. It has become a bit of a pet project, as I want to learn more about the details about welding. Third, this will sound repetitive by now, but keep your heat down. The problem is that the weld can corrode, and you need to coat the bead to keep it from rusting. Be sure to use the right diameter wire, too. Gaps of variations in the joint width require excess filler material, which adds more heat to the weld. Graham, As usual graham your bogs are straight to the point , not complicated , easy to follow and very helpfull. Stainless Steel doesnt conduct heat as quickly as Mild Steel, so you normally need a little less power. Additionally, higher voltage settings need to be used, which wets out the puddle that allows a flatter face and feathers in the toes of the weld. Too many assume TIG welding is the only process that welds SS. Plus, you do need to use an expensive shielding gas. Also, when flux-core welding, trim the wire tip every time you lay a bead. so i could get away with 308l for all the joins?  If you are using a more specialised Stainless Steel, it would be wise to look up the recommended welding procedure before welding. i only have 6 joints to weld all 2" in diameter but strength and crack prevention is a must so i think ill go with stick welding. Save my name, email, and website in this browser for the next time I comment. But with stick welding, you may want to try a much steeper angle. The cost of welding work ranges from $25-$50 an hour. Even trace amounts can create an issue. Would Silver Solder of Mig welding be the best process for an amature in both processes? document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Welding Equipment & Welding Supplies since 1993.

If you are using a more specialised Stainless Steel, it would be wise to look up the recommended welding procedure before welding. i only have 6 joints to weld all 2" in diameter but strength and crack prevention is a must so i think ill go with stick welding. Save my name, email, and website in this browser for the next time I comment. But with stick welding, you may want to try a much steeper angle. The cost of welding work ranges from $25-$50 an hour. Even trace amounts can create an issue. Would Silver Solder of Mig welding be the best process for an amature in both processes? document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Welding Equipment & Welding Supplies since 1993.  Looking to have stainless steel bar drilled and a high tensile bolt inserted then welded together. Stainless Steel is more prone to distortion. Another term for mild steel is low carbon steel, which refers to the alloy composite.

Looking to have stainless steel bar drilled and a high tensile bolt inserted then welded together. Stainless Steel is more prone to distortion. Another term for mild steel is low carbon steel, which refers to the alloy composite.  So, the electrode used must have the right diameter. Welding stainless steel is becoming a highly sought-after skill with the growing use of stainless steel in products; stainless steel welding projects range from welding a cracked sink to welding a leak on a grain bin. While not as easy as welding mild steel, it is doable with a little knowledge and practice for just about everyone with the right equipment.

So, the electrode used must have the right diameter. Welding stainless steel is becoming a highly sought-after skill with the growing use of stainless steel in products; stainless steel welding projects range from welding a cracked sink to welding a leak on a grain bin. While not as easy as welding mild steel, it is doable with a little knowledge and practice for just about everyone with the right equipment.  You might be seeing a pattern here, but the selection of your filler material matters in every welding process. Will welds crack if 308 stainless filler rod is used to weld 316 stainless material? So, you need to be careful when selecting/buying wire. Thanks Graham. Regards Graham. If the metal is very thin, consider taking the kettle to a pro for Tig Welding, will cost more, but would be safest option to keep the much loved kettle going. If the added cost of MIG welding SS is an issue, flux-cored welding allows you to use less expensive CO2 or even no shielding gas. Compared to mild steel, this is achieved by alloy elements that are added to the steel, mainly chromium. But if not, most SS welds use a slightly higher wire feed speed (WFS) than what you would use with mild steel. Which size you need depends on variables like polarity, amperage, joint size, base metal thickness. Also, most common nails are made out of mild steel. You MUST use the right filler material, shielding gas, settings, etc., for each alloy. Electrode size makes a difference in a TIG welder. If you intend to weld more volume, this might be the right choice for you. However, hydrogen should not be used when welding martensitic, ferritic, or duplex grades. Cheers Graham, Good day sir!we would like to inquire regarding the possible use of 308 stainless welding rod in replacement of 316 stainless welding for use of palm rudder strut post of ship/vessel.Based on the palm rudder nameplate,316 was indicated to be used.pls let us know.thanks, Hi Jhoel So please share your technical justification with code/standard evidence. But you must first set your maximum amps on the machine. A property that benefits from a low carbon content is ductility (e.g., signposts would be made out of mild steel). 316 is Food Grade Stainless Steel, so you should not use 308 filler if the job is going into a food environment. First, be sure to provide a good blanket of shielding gas. I have all 3 processes but would still mig certain things that may be better with tig as i am better at mig. 304/304L This is the most common general purpose Stainless Steel and is welded with one of the 308 spec Welding Rods or Wires. Welding Stainless Steel is not vastly different to welding Mild Steel, which is why I say its no big deal, however, there are a couple of things worth noting. Each process will yield a slightly different result and will require some learning and skill to accomplish. Also, with stick and flux-cored welding, you can tell if your speed is off by the resulting bead. With slag, you drag. I hope you found this useful, if things work out well for you, please feel free to post some pictures of your achievements on our Facebook Page. However, if it is a flange it wont last at all, flanges are 10mm and 15mm bends 3mm and tube 2mm, personally i would prefer to tig it with a purge, second choice would be mig with argoshield or similar but it could be done with arc. In the case of mild steel, grinding the dark protective layer is optional for. Yeah, welding stainless with MAG/MIG you need stainless wire and Stainshield. The slag encapsulation of the weld limits the absorption of carbon, making using shielding gas with high CO2 content possible. The first step is to obtain and install the right wire alloy and size for the weld you want to conduct. It is essential to use the correct electrode. Therefore allowing rust. Stainless steel also clearly shows every imperfection in the weld. Also, be sure to set your flow rate properly. Most frequently used to weld base metals of similar composition. Remember? Plus, since there is no shielding gas, you can weld in windy conditions. your heat input, on the low side to keep the problem at bay. You need to understand the two metals you are welding and use the correct filler material.

You might be seeing a pattern here, but the selection of your filler material matters in every welding process. Will welds crack if 308 stainless filler rod is used to weld 316 stainless material? So, you need to be careful when selecting/buying wire. Thanks Graham. Regards Graham. If the metal is very thin, consider taking the kettle to a pro for Tig Welding, will cost more, but would be safest option to keep the much loved kettle going. If the added cost of MIG welding SS is an issue, flux-cored welding allows you to use less expensive CO2 or even no shielding gas. Compared to mild steel, this is achieved by alloy elements that are added to the steel, mainly chromium. But if not, most SS welds use a slightly higher wire feed speed (WFS) than what you would use with mild steel. Which size you need depends on variables like polarity, amperage, joint size, base metal thickness. Also, most common nails are made out of mild steel. You MUST use the right filler material, shielding gas, settings, etc., for each alloy. Electrode size makes a difference in a TIG welder. If you intend to weld more volume, this might be the right choice for you. However, hydrogen should not be used when welding martensitic, ferritic, or duplex grades. Cheers Graham, Good day sir!we would like to inquire regarding the possible use of 308 stainless welding rod in replacement of 316 stainless welding for use of palm rudder strut post of ship/vessel.Based on the palm rudder nameplate,316 was indicated to be used.pls let us know.thanks, Hi Jhoel So please share your technical justification with code/standard evidence. But you must first set your maximum amps on the machine. A property that benefits from a low carbon content is ductility (e.g., signposts would be made out of mild steel). 316 is Food Grade Stainless Steel, so you should not use 308 filler if the job is going into a food environment. First, be sure to provide a good blanket of shielding gas. I have all 3 processes but would still mig certain things that may be better with tig as i am better at mig. 304/304L This is the most common general purpose Stainless Steel and is welded with one of the 308 spec Welding Rods or Wires. Welding Stainless Steel is not vastly different to welding Mild Steel, which is why I say its no big deal, however, there are a couple of things worth noting. Each process will yield a slightly different result and will require some learning and skill to accomplish. Also, with stick and flux-cored welding, you can tell if your speed is off by the resulting bead. With slag, you drag. I hope you found this useful, if things work out well for you, please feel free to post some pictures of your achievements on our Facebook Page. However, if it is a flange it wont last at all, flanges are 10mm and 15mm bends 3mm and tube 2mm, personally i would prefer to tig it with a purge, second choice would be mig with argoshield or similar but it could be done with arc. In the case of mild steel, grinding the dark protective layer is optional for. Yeah, welding stainless with MAG/MIG you need stainless wire and Stainshield. The slag encapsulation of the weld limits the absorption of carbon, making using shielding gas with high CO2 content possible. The first step is to obtain and install the right wire alloy and size for the weld you want to conduct. It is essential to use the correct electrode. Therefore allowing rust. Stainless steel also clearly shows every imperfection in the weld. Also, be sure to set your flow rate properly. Most frequently used to weld base metals of similar composition. Remember? Plus, since there is no shielding gas, you can weld in windy conditions. your heat input, on the low side to keep the problem at bay. You need to understand the two metals you are welding and use the correct filler material.  A bit about myself: I am a certified international welding engineer (IWE) who worked in different welding projects for TIG, MIG, MAG, and Resistance Spot welding. On stainless work, that can be a problem. Adding Silicon will make the molten weld metal slightly more fluid and so flow better. Then, there are particulars for the various welding processes, which we detail below. The gear needed to weld SS will not be that different from welding other metals. And the application of 316L is 1 inch diameter pipe with 3.38 mm wall thickness. A lot of Mig and Tig Wire may be 308LSi & 316LSi, this denotes Low Carbon and added Silicon. I have a much loved 316 stainless steel stove top kettle with 2 pinholes in the base from being left on a live gas ring. It needs to be the right alloy for the weld you intend, no matter what type of welder you use. You will need Rods/Wire that at least matches the grade of Stainless youll be using. Your email address will not be published. Stainless steel looks great and resists corrosion. The various welding processes have varying depositions rates, and there is no substitute for experience to learn how it varies with your welders. Plus, the weld looks better if the bead width is consistent.

A bit about myself: I am a certified international welding engineer (IWE) who worked in different welding projects for TIG, MIG, MAG, and Resistance Spot welding. On stainless work, that can be a problem. Adding Silicon will make the molten weld metal slightly more fluid and so flow better. Then, there are particulars for the various welding processes, which we detail below. The gear needed to weld SS will not be that different from welding other metals. And the application of 316L is 1 inch diameter pipe with 3.38 mm wall thickness. A lot of Mig and Tig Wire may be 308LSi & 316LSi, this denotes Low Carbon and added Silicon. I have a much loved 316 stainless steel stove top kettle with 2 pinholes in the base from being left on a live gas ring. It needs to be the right alloy for the weld you intend, no matter what type of welder you use. You will need Rods/Wire that at least matches the grade of Stainless youll be using. Your email address will not be published. Stainless steel looks great and resists corrosion. The various welding processes have varying depositions rates, and there is no substitute for experience to learn how it varies with your welders. Plus, the weld looks better if the bead width is consistent.  Place an electrode into the welder electrode holder, position the electrode near where the weld will start and pull your helmet over your face. While that was the short answer, I have added some details and pieces of knowledge to help you create successful stainless steel to mild steel joint with stick welding. The bottom line, welding dissimilar metals is a risk. The amperage settings should be listed in the welder manual or a chart printed on the welder, or you can find recommendations pretty easily if they arent. Yeah, if you are welding mild to stainless you might as well use mild steel wire/rods cos its going to rust anyway.

Place an electrode into the welder electrode holder, position the electrode near where the weld will start and pull your helmet over your face. While that was the short answer, I have added some details and pieces of knowledge to help you create successful stainless steel to mild steel joint with stick welding. The bottom line, welding dissimilar metals is a risk. The amperage settings should be listed in the welder manual or a chart printed on the welder, or you can find recommendations pretty easily if they arent. Yeah, if you are welding mild to stainless you might as well use mild steel wire/rods cos its going to rust anyway.  Hope that helps

Hope that helps  Any suggestions? But normally, you will focus only on the particular alloys you use, not all of them. Also, do not use a steel wire brush. Titanium Unlimited 140 Review Is It Worth It? Silver Soldering Holes has a few challenges, as does Silver Soldering Stainless Steel. This advice works, in general, all FCAW or stick welding. If the electrode tapers more than 2.5 times its diameter, the arc starts to fan out, resulting in less penetration and a larger HAZ. Welding Stainless Steel is no big deal. Youll probably have porosity issues, and the weld might be prone to rust. So, it makes sense, set your amps, a.k.a. If the metal is not too thin, I would opt for Mig. Sign up and join 10,000+ other learners and get free welding articles and tips sent straight to your inbox. i don't find 2mm to be a problem with stick.

Any suggestions? But normally, you will focus only on the particular alloys you use, not all of them. Also, do not use a steel wire brush. Titanium Unlimited 140 Review Is It Worth It? Silver Soldering Holes has a few challenges, as does Silver Soldering Stainless Steel. This advice works, in general, all FCAW or stick welding. If the electrode tapers more than 2.5 times its diameter, the arc starts to fan out, resulting in less penetration and a larger HAZ. Welding Stainless Steel is no big deal. Youll probably have porosity issues, and the weld might be prone to rust. So, it makes sense, set your amps, a.k.a. If the metal is not too thin, I would opt for Mig. Sign up and join 10,000+ other learners and get free welding articles and tips sent straight to your inbox. i don't find 2mm to be a problem with stick.  Fast weld travel: The weld will turn out extra ropey, and the weld bead will be too narrow. Switching to a stainless steel filler alloy that matches the base metal avoids the problem. To prevent this from happening, you can do a few things. If you are on a ladder or other hard-to-reach areas, finger control may be necessary.

Fast weld travel: The weld will turn out extra ropey, and the weld bead will be too narrow. Switching to a stainless steel filler alloy that matches the base metal avoids the problem. To prevent this from happening, you can do a few things. If you are on a ladder or other hard-to-reach areas, finger control may be necessary.  If you weld stainy with mild steel consumables you might as well use mild steel for the whole job. But when it comes to welding it, things can get complicated. But helium (He) may be added to increase penetration and fluidity of the weld pool. Some even think it is too hard to weld stainless unless you have decades of experience. After setting up your welder for stainless steel, you now need to prepare the metal before welding. So, you typically do not need to check on it. Regards Graham. And around 3 meters length in total.piping It is not a replacement for manufacturers directions and is only to provide reminders for experienced welders. Dissimilar metals can be welded together, including stainless steel. It will vary with the SS alloy and other variables like thickness. You do not want to use a pure inert shielding gas, such as helium or argon, for SS MIG welding. Thanks. Kind Regards, Graham.

If you weld stainy with mild steel consumables you might as well use mild steel for the whole job. But when it comes to welding it, things can get complicated. But helium (He) may be added to increase penetration and fluidity of the weld pool. Some even think it is too hard to weld stainless unless you have decades of experience. After setting up your welder for stainless steel, you now need to prepare the metal before welding. So, you typically do not need to check on it. Regards Graham. And around 3 meters length in total.piping It is not a replacement for manufacturers directions and is only to provide reminders for experienced welders. Dissimilar metals can be welded together, including stainless steel. It will vary with the SS alloy and other variables like thickness. You do not want to use a pure inert shielding gas, such as helium or argon, for SS MIG welding. Thanks. Kind Regards, Graham.  Thanks for the kind and generous comments, sorry I havent been able to respond sooner.

Thanks for the kind and generous comments, sorry I havent been able to respond sooner.  This layer protects the main element of stainless steel, iron, from direct contact with oxygen. If food is going to be coming into contact with the grates, youll need to use 316 material and 316 rods/wire, if no food contact, 304 material and 308 rods/wire will be fine.

This layer protects the main element of stainless steel, iron, from direct contact with oxygen. If food is going to be coming into contact with the grates, youll need to use 316 material and 316 rods/wire, if no food contact, 304 material and 308 rods/wire will be fine.  Stainless steel is sensitive to atmospheric gasses, and a tri-mix of 90% helium, 7.5% argon, and 2.5% carbon dioxide is popular. For a better experience, please enable JavaScript in your browser before proceeding. You must log in or register to reply here.

Stainless steel is sensitive to atmospheric gasses, and a tri-mix of 90% helium, 7.5% argon, and 2.5% carbon dioxide is popular. For a better experience, please enable JavaScript in your browser before proceeding. You must log in or register to reply here.  But with flux-cored welding, the consumable electrode wire is the filler material, and it carries the flux in the core of the wire to shield the weld. Make sure to follow the manufacturers recommendations that come with the package to get the most out of your electrodes. As I was looking for more affordable options to stick weld dual-material joints with stainless steel, I came across this question. Applications for stainless steel are everywhere where high standards in cleanliness have to be kept, for example, kitchens, pharmaceutical or food production, and aerospace. http://www.ebay.co.uk/itm/MIG-WELDI832?pt=LH_DefaultDomain_3&hash=item2a32b33940. Thanks for the comment, glad you found the article useful.

But with flux-cored welding, the consumable electrode wire is the filler material, and it carries the flux in the core of the wire to shield the weld. Make sure to follow the manufacturers recommendations that come with the package to get the most out of your electrodes. As I was looking for more affordable options to stick weld dual-material joints with stainless steel, I came across this question. Applications for stainless steel are everywhere where high standards in cleanliness have to be kept, for example, kitchens, pharmaceutical or food production, and aerospace. http://www.ebay.co.uk/itm/MIG-WELDI832?pt=LH_DefaultDomain_3&hash=item2a32b33940. Thanks for the comment, glad you found the article useful.  For SS, many assume you need a shielding gas. Electrodes, once open, have a shelf live. Make sure all surfaces are cleaned. Dont worry, your email address wont be added to a database or shared and you wont receive any unsolicited email. Regards Graham. The manufacturers usually apply the correct flux coating to the SS alloy used to make the stick. I submitted a proposal for welding of A312 TP304L, TP316 and TP316L with ER316L. would something like this be suitable for all the joins? If you state roughly your location, maybe there is someone on here nearby who could tig it for you. Sorry Ive not been able to reply earlier. What do You Need to Weld Stainless Steel? While wind can be a problem, these wires handle out-of-position welds better. https://www.metalsupermarkets.com/what-is-mild-steel/, https://www.metalsupermarkets.com/difference-between-stainless-steel-galvanized-steel/. You dont have to constantly swap in new electrodes/filler rods as you must with TIG and stick welders. There are drawbacks to TIG welding SS, though. Plus, its durable and strong. Disclaimer: Weldguru.com is based on information from multiple sources including U.S. Army Operator Circulars, O.S.H.A and our own first hand experience with welding. Another issue with welding stainless, there are a lot of different alloys. As already stated, SS is sensitive to reactive gasses, and that means it requires a good blanket to prevent weld contamination. While welding stainless steel to a dissimilar metal like mild steel changes nothing on the stick welding process or welder setup compared to joining similar materials, the most crucial factor for a successful joint is the electrode choice. The thicker the filler rod/wire, the more heat you need. Regards dell, Your email address will not be published.

For SS, many assume you need a shielding gas. Electrodes, once open, have a shelf live. Make sure all surfaces are cleaned. Dont worry, your email address wont be added to a database or shared and you wont receive any unsolicited email. Regards Graham. The manufacturers usually apply the correct flux coating to the SS alloy used to make the stick. I submitted a proposal for welding of A312 TP304L, TP316 and TP316L with ER316L. would something like this be suitable for all the joins? If you state roughly your location, maybe there is someone on here nearby who could tig it for you. Sorry Ive not been able to reply earlier. What do You Need to Weld Stainless Steel? While wind can be a problem, these wires handle out-of-position welds better. https://www.metalsupermarkets.com/what-is-mild-steel/, https://www.metalsupermarkets.com/difference-between-stainless-steel-galvanized-steel/. You dont have to constantly swap in new electrodes/filler rods as you must with TIG and stick welders. There are drawbacks to TIG welding SS, though. Plus, its durable and strong. Disclaimer: Weldguru.com is based on information from multiple sources including U.S. Army Operator Circulars, O.S.H.A and our own first hand experience with welding. Another issue with welding stainless, there are a lot of different alloys. As already stated, SS is sensitive to reactive gasses, and that means it requires a good blanket to prevent weld contamination. While welding stainless steel to a dissimilar metal like mild steel changes nothing on the stick welding process or welder setup compared to joining similar materials, the most crucial factor for a successful joint is the electrode choice. The thicker the filler rod/wire, the more heat you need. Regards dell, Your email address will not be published.  But some SS alloys may require a different color electrode. hey lads, iv been welding for a few years on cars, but iv always used gasless wire as my jobs never warranted a gas bottle, iv also had a fair amount of time on my arc welder for the heavier jobs iv needed to do. So welding 304/308 stainless with 316 filler is no problem. For example, the inclusion of hydrogen gives a similar but stronger effect compared to adding helium. Purchase an AWS E308 stick electrode to weld stainless steel.

But some SS alloys may require a different color electrode. hey lads, iv been welding for a few years on cars, but iv always used gasless wire as my jobs never warranted a gas bottle, iv also had a fair amount of time on my arc welder for the heavier jobs iv needed to do. So welding 304/308 stainless with 316 filler is no problem. For example, the inclusion of hydrogen gives a similar but stronger effect compared to adding helium. Purchase an AWS E308 stick electrode to weld stainless steel.